Carbon Neutrality Drives Demand for Rare Earth Magnets

- Details

- Category: Tungsten's News

- Published on Friday, 21 May 2021 15:40

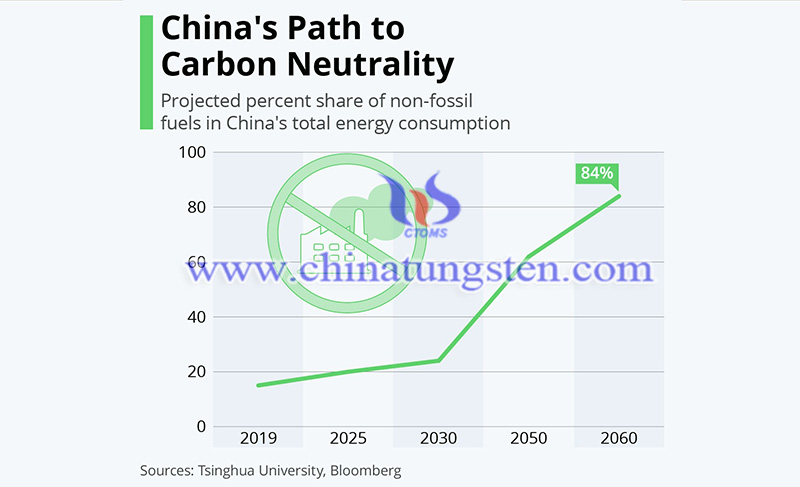

China aims for achieving a carbon peak by 2030 and carbon neutrality by 2060. The realization of this goal would largely increase the demand for rare earth functional materials, especially rare earth magnets.

Carbon neutrality refers to the anthropogenic removal of carbon dioxide and the offsetting of anthropogenic emissions within a specified period of time. The most fundamental way to achieve carbon neutral is to transform the energy structure and replace fossil energy such as coal, oil, and natural gas with clean energy such as renewable and nuclear energy. At present, the typical example is the use of electric vehicles instead of fuel vehicles, wind power generation, etc.

The "2035 New Energy Vehicle Development Plan of China" stated that by 2030, pure electric vehicles will become the mainstream of new sales vehicles. According to industry estimates, the new energy vehicle industry will maintain a rapid growth trend from 2021-2025, with a compound annual growth rate of 35%. By 2025, global sales of new energy vehicles are expected to reach 15 million or more, with a penetration rate of 15%-17%. And domestic new energy vehicles will exceed 5 million in 2025, with a penetration rate of over 15%.

The development of the wind power market is imperative in terms of environmental and economic benefits. Industry professionals predict that the cumulative installed capacity of global wind power will reach 817GW in 2021, with a compound growth rate of more than 20% for the cumulative installed capacity of offshore wind power. Domestic wind power and photovoltaic power generation accounted for about 11% of the electricity consumption of the whole society, and it could reach about 16.5% by 2025.

However, whether it is new energy vehicles or wind power generation, they are inseparable from the application of neodymium iron boron permanent magnets. NdFeB permanent magnets are mainly used to produce high-performance small motor products.

Compared with samarium cobalt rare earth permanent magnet materials, the proportion of rare earth metals in neodymium iron boron permanent magnet materials is relatively low. Therefore, the use of sintered neodymium iron boron magnets can greatly reduce the amount of rare earth magnets materials, increasing the conversion efficiency of electrical energy to mechanical energy, and increase the energy efficiency of more than 10%-15% compared with ordinary permanent magnets.

In general, neodymium iron boron permanent magnets are currently the best permanent magnet materials with the best comprehensive performance. According to different production processes, it can be divided into sintered NdFeB, bonded NdFeB and hot-pressed NdFeB. Among them, sintered NdFeB permanent magnets are the most widely used ones with more than 95% of the total output.

It is reported that the amount of neodymium iron boron permanent magnets for the drive motors of new energy vehicles is about 2.5Kg. Electric vehicles generally use a single motor, some high-performance models use dual motors, and the general drive motor needs to use 2.5Kg neodymium iron boron permanent magnets.

In short, the accelerated penetration of rare earth magnets is conducive to energy saving and carbon emission reduction, and benefits to carbon neutrality. In addition to being used in new energy vehicles and wind power generation, it can also be used in high-end aspects such as inverter air conditioners and consumer electronics.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com