SLM Selective Laser Melting Technology Can Print Pure Tungsten Materials

- Details

- Category: Tungsten's News

- Published on Sunday, 11 November 2018 20:27

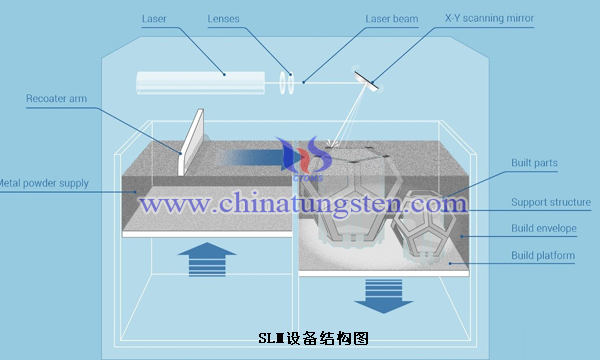

Additional material manufacturing is a new processing technology, commonly known as 3D printing, which is different from the traditional "removal" manufacturing. It does not need the original embryo and die. It directly forms any complex shape object by adding material layer by layer according to the computer three-dimensional model data of parts.

Selective Laser Melting (SLM) was first proposed by the Froounholfer Institute in Germany in 1995 and works in a similar way to SLS. SLM converts the energy of the laser into heat to shape the metal powder. The main difference is that the SLS is not completely melted during the manufacturing process, and the SLM is heated during the manufacturing process until it is completely melted. Adhesives, molding accuracy and mechanical properties are better than SLS. However, because the SLM has no thermal field, it needs to heat the metal from a normal temperature of 20 degrees Celsius to a melting point of thousands of degrees. This process consumes a huge amount of energy.

At present, SLM technology has prominent technological advantages in the fields of complex dies, personalized medical parts, aerospace and automobile. Most of the researches at home and abroad only focus on the manufacturing of additives for titanium alloy, stainless steel, nickel-based alloy and other materials. However, for refractory metals and their alloys, such as tungsten, molybdenum, tantalum and vanadium, it is difficult to make significant progress because of their inherent physical properties such as high melting point, density, thermal conductivity, melt tension and viscosity. The main defects of refractory metals such as tungsten and molybdenum are unstable droplets, remarkable spheroidization and low density.

There are already feasible solutions for the manufacture of tungsten alloy by SLM technology. The process and method are mainly W-Fe, W-Ni, W-Cu, etc. Fe, Ni or Cu is used as a bonding material to melt under the action of heat source. The inclusion of unmelted tungsten particles and bonding to each other is a typical analog liquid phase sintering process, which can reduce the difficulty of forming tungsten alloys. However, pure tungsten additive is not so easy. Compared with tungsten alloy, pure tungsten molding must be based on complete melting/solidification process. Due to the very high melting point and thermal conductivity of tungsten, the spreading/solidification behavior of droplets under the action of heat source It is more complicated and it is difficult to achieve complete compactness. Therefore, the additive forming process and method of pure tungsten have not been broken.

With the continuous progress of human beings in space, military, space exploration and other fields, the requirement for raw materials with special properties is getting higher and higher. When 3D printed tungsten materials use metal cobalt and nickel as bonding phases, the metal bonding phases promote the densification of alloys, but also reduce their hardness, wear resistance, corrosion resistance and oxidation resistance. Because of the difference of thermal expansion coefficients between metal phase and hard phase such as tungsten carbide, the thermal stress of material is larger, so its application field is limited.

Recently, regarding the SLM technology printing additive manufacturing scheme of refractory metals such as pure tungsten, the research team of Tsinghua University in Beijing has made a breakthrough. They use special pretreatment methods and process measures to ensure the dense molding of pure tungsten metal. The measures of the technical process ensure that the defects of pure tungsten additive forming are reduced and the density is increased.

In the process of pure tungsten additive manufacturing, the researchers first took spherical pure tungsten powder particles with no impurities and oxygen adsorption on the surface, and selected large particles of tungsten powder and small particles of tungsten powder, and tungsten powder in a ratio of 7:3. The small particles are mixed with the large particles of the tungsten powder to obtain a mixed powder, and then the rare earth lanthanum and the carbon black are added to the mixed powder in proportion to prepare a pure tungsten additive precursor.

Then a multi-layer composite iron-insulating material-tungsten substrate is installed on the working platform of the material-adding equipment. The temperature is preheated to 300 ℃ and maintained during laser forming and remelting. In the glove box protected by argon, the mixed powders are filled into the powder silo, and the protective gas argon is input into the forming chamber. The vacuum is relatively true. The vacant degree is -90KPa. The powder mixing mechanism is used to feed the mixed powder in the powder silo onto the multi-layer composite iron-insulation material-tungsten substrate and flatten it to obtain a thin layer of mixed powder having a thickness of 30 um, and then start to operate the additive equipment to form a section. After the time, the parts are formed, and a pure tungsten additive product having a tungsten molding density of 18 g/cm3 or more and a relative density of 93% or more is obtained.

The Chinese team adopted the optimization of the proportion of spherical tungsten powder and the assurance of forming process measures to solve the problems of unstable droplet state, spheroidization and more defective holes in the manufacture of pure tungsten metal additives, improve the density of forming and the performance of components, and achieve the high density required by finished products. The technology has been applied to complex dies and personalities. There are great potential applications in the fields of chemical medicine, aerospace and automobile manufacturing. (China Tungsten online: Weiping)

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com