Performance Comparison of Tungsten and Aluminum Targets

- Details

- Category: Tungsten Information

- Published on Thursday, 11 September 2025 20:27

In the fields of thin film deposition and semiconductor manufacturing, the choice of target material is crucial for process efficiency and product quality. Aluminum and tungsten targets, as two commonly used materials in sputtering processes, have distinct application focuses due to differences in their physical and chemical properties.

Aluminum targets, due to their lightweight nature, low cost, and high electrical conductivity, are widely used in optical coatings, decorative coatings, and thin film preparation for certain electronic devices. In display panels, mirror coatings, and transparent conductive layers of solar cells, aluminum targets can form thin films with high reflectivity and conductivity, meeting optical and electrical performance requirements. Their lower material cost and ease of processing provide an economic advantage in large-scale production, making them suitable for cost-sensitive industries such as architectural glass coatings and decorative coatings. However, aluminum targets’ low melting point limits their use in high-temperature environments. During high-power sputtering, aluminum targets are prone to softening or deforming due to thermal loads, leading to reduced sputtering efficiency and increased thin film defects. Additionally, aluminum’s poor corrosion resistance makes it susceptible to chemical reactions in sputtering environments with reactive gases, forming an aluminum oxide layer that affects the purity and performance of the thin film. Aluminum’s lower mechanical strength also makes its surface prone to damage or deformation under high-energy ion bombardment, further impacting the uniformity and durability of the thin film.

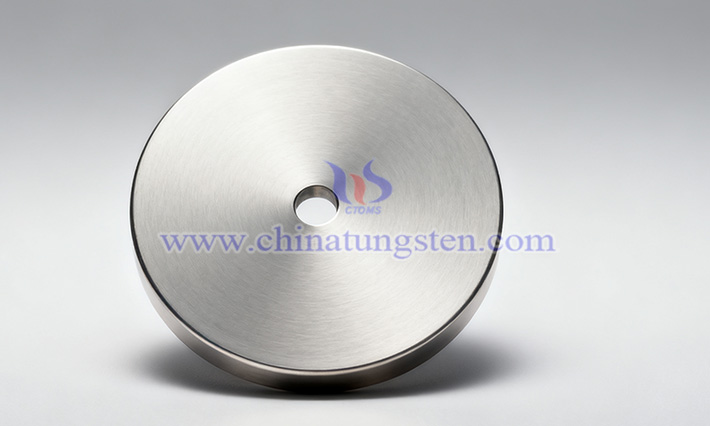

In stark contrast, tungsten targets stand out in demanding sputtering processes due to their high density, high melting point, and excellent chemical stability. Their body-centered cubic crystal structure, combined with a low thermal expansion coefficient, allows tungsten targets to maintain dimensional and structural stability during high-power sputtering, effectively preventing thermal deformation or surface cracks. This makes them suitable for applications such as depositing semiconductor barrier layers, diffusion barrier layers, and back electrodes for new energy batteries. Moreover, tungsten targets’ strong chemical stability resists corrosion from acids, alkalis, and oxidizing gases, while their high density ensures uniform atom release, reducing impurity contamination and extending service life. This provides dense, uniform thin films for high-performance devices such as solar cell back electrodes, optical filters, and high-temperature wear-resistant coatings. However, tungsten targets have limitations that cannot be ignored. Compared to aluminum, tungsten has lower electrical conductivity, making it less effective in applications requiring high conductivity (e.g., certain optical or conductive coatings). Additionally, the higher processing difficulty and preparation cost of tungsten targets limit their use to some extent.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com