Performance Comparison of Tungsten and Titanium Targets

- Details

- Category: Tungsten Information

- Published on Thursday, 11 September 2025 20:31

In the fields of thin film deposition and semiconductor manufacturing, the choice of target material plays a crucial role in process stability and product quality. Titanium and tungsten targets, as two commonly used sputtering materials, each offer distinct advantages in different application scenarios due to their unique physical and chemical properties.

Titanium targets, with their excellent corrosion resistance and biocompatibility, are widely used in the thin film preparation for medical, aerospace, and industrial coatings. Titanium can form a stable oxide layer in mild chemical environments, effectively resisting corrosion, making it suitable for surface coatings on implantable medical devices, such as wear-resistant layers for artificial joints or dental implants, as well as protective coatings for aerospace components. Additionally, titanium targets have relatively low processing costs and are easy to prepare, making them suitable for mid-to-low-end industrial applications. However, titanium targets have a lower melting point and density compared to tungsten targets, and during high-power sputtering, thermal loads may cause surface performance fluctuations or even generate particulate contamination, affecting the uniformity and quality of the thin film.

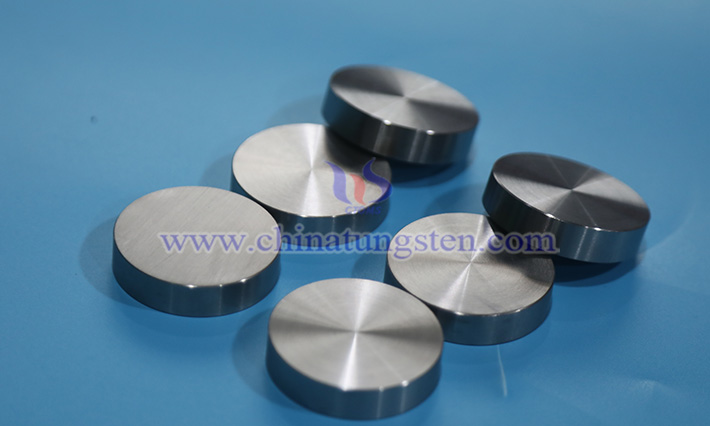

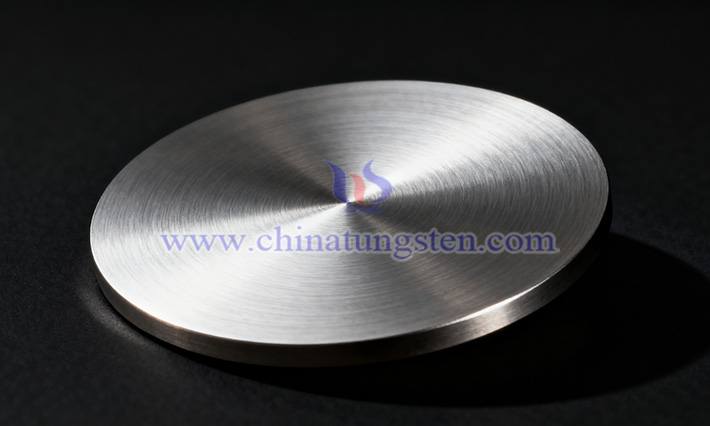

In contrast, tungsten targets demonstrate unique advantages in semiconductor production and optical coating fields due to their high density, high melting point, and excellent thermal stability. The combination of their body-centered cubic crystal structure and low thermal expansion characteristics allows them to effectively avoid thermal deformation or surface degradation in high-power sputtering environments. This property makes tungsten targets particularly effective in long-duration, high-intensity sputtering processes, suitable for depositing gate electrodes, barrier layers in integrated circuits, and anti-reflective coatings for optical lenses. However, tungsten targets have limitations, including lower electrical conductivity, which makes them less effective than titanium targets in applications requiring high conductivity. Furthermore, the higher processing difficulty and preparation cost of tungsten targets limit their use in cost-sensitive scenarios to some extent.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com