Performance Comparison of Tungsten and Copper Targets

- Details

- Category: Tungsten Information

- Published on Thursday, 11 September 2025 20:22

In the fields of semiconductor manufacturing and thin film deposition, the choice of target material significantly impacts process efficiency and product quality. Copper and tungsten targets, as two common sputtering targets, each have distinct advantages and disadvantages in terms of physical properties, chemical stability, and application scenarios.

Copper targets, due to their excellent electrical conductivity and relatively low cost, are widely used in the semiconductor industry for depositing interconnect layers. Copper’s high conductivity makes it an ideal choice for preparing low-resistance thin films, particularly in forming conductive paths such as interconnect lines and contact layers in integrated circuits. Its lower material cost and mature processing technology further reduce production expenses, giving copper targets a significant economic advantage in large-scale production.

However, copper targets have a low melting point, and during high-power sputtering, their surface is prone to degradation due to high temperatures, potentially generating particulate contamination. These particles may deposit onto the thin film, leading to defects that can affect the electrical performance and reliability of chips. Additionally, copper is susceptible to oxidation reactions in complex chemical environments (e.g., oxygen-containing sputtering atmospheres), forming a copper oxide layer. This not only reduces sputtering efficiency but may also introduce impurities, further degrading thin film quality. These limitations restrict the use of copper targets in high-precision, high-reliability processes.

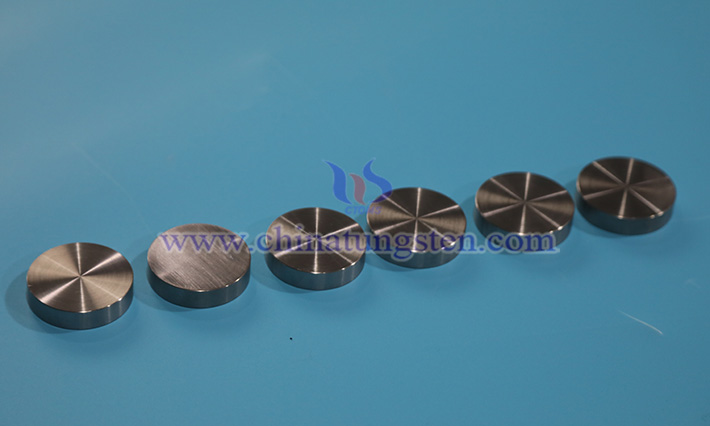

In contrast, tungsten targets excel in demanding process environments due to their excellent high-temperature resistance and chemical stability. With a melting point as high as 3,422°C, far exceeding that of copper targets, tungsten’s body-centered cubic crystal structure provides outstanding mechanical strength and thermal stability. Under high-energy ion bombardment, tungsten targets maintain relatively intact structural integrity, making them suitable for long-duration, high-intensity sputtering processes, such as depositing semiconductor barrier layers or diffusion barrier layers. Moreover, in sputtering environments containing reactive gases like oxygen, nitrogen, or sulfur, tungsten targets resist oxidation and corrosion reactions, effectively suppressing impurity formation and ensuring the purity and consistency of the deposited thin films.

However, tungsten targets also have certain limitations. Compared to copper, tungsten has lower electrical conductivity, making it less effective for low-resistance interconnect layer applications. Additionally, the higher processing difficulty and preparation cost of tungsten targets limit their use in large-scale, low-cost production to some extent.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com