Performance Comparison of Tungsten and Molybdenum Targets

- Details

- Category: Tungsten Information

- Published on Thursday, 11 September 2025 20:19

In the fields of thin film deposition and advanced manufacturing, the choice of target material significantly impacts process efficiency and product quality. Molybdenum and tungsten targets, as refractory metal targets, are widely used in the production of solar cells, display panels, and high-temperature coatings due to their high melting points and chemical stability.

Molybdenum targets excel in various sputtering processes due to their high melting point and good electrical conductivity, making them suitable for depositing back electrodes in solar cells (e.g., CIGS cells), conductive layers in display panels, and high-temperature wear-resistant coatings. Their superior thermal conductivity ensures effective heat dissipation during sputtering, making them ideal for low- to medium-power sputtering processes. Molybdenum targets are relatively low-cost to process, easy to prepare, and possess high mechanical strength, enabling them to withstand moderate ion bombardment, which suits mid-range industrial applications.

However, molybdenum’s lower density compared to tungsten targets results in slightly reduced sputtering efficiency and thin film uniformity. In high-power sputtering, molybdenum targets may experience microscopic damage, such as surface cracks or wear, due to thermal loads or high-energy ion bombardment, affecting long-term stability. Additionally, in certain high-corrosion environments (e.g., fluorine- or chlorine-containing gases), molybdenum targets are prone to surface erosion, forming oxide or compound layers that can degrade sputtering performance and introduce impurities, impacting thin film quality.

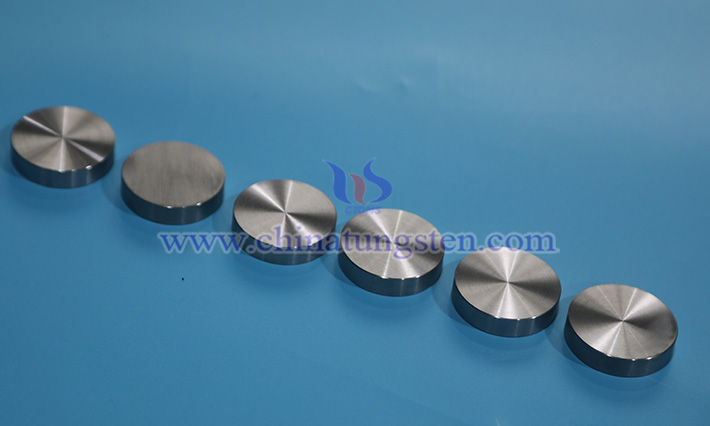

In contrast, tungsten targets demonstrate significant advantages in high-power sputtering and complex chemical environments, thanks to their high density, high melting point, and excellent thermal conductivity. Tungsten’s high melting point and low thermal expansion coefficient allow it to maintain structural integrity under high temperatures and ion bombardment, preventing thermal deformation or surface degradation. This makes tungsten targets suitable for high-precision, long-duration sputtering processes, such as depositing semiconductor barrier layers, optical coatings, or thin films in new energy applications (e.g., fuel cells and CIGS solar cell back electrodes). Another key advantage is its excellent chemical stability, enabling tungsten targets to resist corrosion effectively in reactive gas environments containing fluorine, oxygen, or sulfur, reducing impurity contamination and extending target lifespan.

However, tungsten targets have limitations, including higher processing difficulty and preparation costs compared to molybdenum targets, which can limit their use in cost-sensitive scenarios. Additionally, tungsten’s electrical conductivity is slightly lower than molybdenum’s, making it less cost-effective in applications requiring high conductivity (e.g., conductive layers in display panels). Therefore, in practical processes, the advantages and disadvantages of both materials must be weighed based on specific requirements.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com