Preparation Method of Nano Tungsten Trioxide Powder

- Details

- Category: Tungsten Patents

- Published on Wednesday, 22 October 2014 09:02

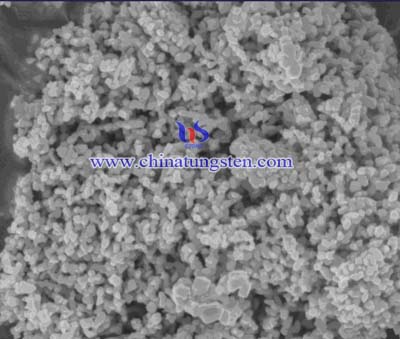

The invention relates to a preparation method of nano tungsten trioxide powder, and belongs to the field of powder metallurgy technology.

The method comprises the following steps: heating a saturated ammonium tungstate solution till 65-70 DEG C, then adding ammonium chloride, tartaric acid, ethylenediamine tetra-n-propionic acid and diethanol amine respectively in sequence, keeping stirring during the adding process till being dissolved completely and continuously stirring for 1-2h; then adding nitric acid under the condition of keeping stirring to form tungstic acid gel; then putting the gel in a heating furnace for drying at 140-150 DEG C, then warming up till 340-380 DEG C for calcination, and finally ball-milling and smashing to obtain the nano tungsten trioxide powder with the average particle size of 23-28 nm. The method disclosed by the invention is mild and stable for reaction process and easy to control, prepared nano tungsten trioxide is thin and uniform in particles and high in powder purity. Moreover, the process is simple and easy to control, so that the industrial production investment is few, the production technology is simple and convenient, the production cost is low, and industrial large-scale production is convenient to realize.

A process for producing a tungsten trioxide powder of nanometer, which is characterized by comprising the steps of: a saturated ammonium tungstate solution was heated to 65-70 ° C, and then ammonium chloride was added an amount of 8-13g / L, stirring 0.5_lh; tartaric acid were added in sequence and, ethylenediaminetetraacetic acid and diethanolamine were added in an amount ll_14g / L ,23-32g / L and 6-9g / L, was stirred to completely dissolve and continue stirring for 1 - 2h; nitric acid was added and stirring was continued for 320-380ml / L, the formation of tungsten acid gel; the gel is placed in a furnace 140-15 (TC drying, heating rate 1_2 ° C / min, heat l_2h, then 2-3 ° C / min heating to 340_38 (TC insulation 2_3h calcination, ball milling to obtain the final nano tungsten trioxide powder.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

sales@chinatungsten.com

sales@chinatungsten.com