New Material Called Tungstenite Has Optical Applications

- Details

- Category: Tungsten Patents

- Published on Tuesday, 05 February 2013 14:26

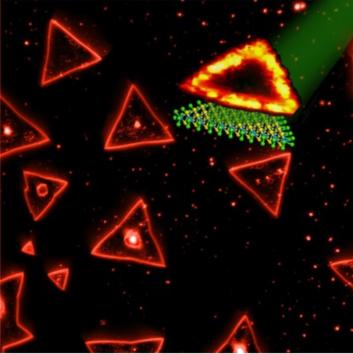

Single layers of tungsten disulfide create triangles that exhibit extraordinary photoluminescence at their edges, while the interior area does not. Credit: Terrones lab/Penn State University

A rare mineral called tungstenite has been formed into thin sheets with possible uses in technologies such as light detectors and lasers, U.S. researchers say.

Stacked in sheets with sulfur atoms, it forms tungsten disulfide in a honeycomb pattern of triangles that have been shown to have unusual light-emitting, or photoluminescent, properties, Penn State researchers reported Monday.

Photoluminescence occurs when a substance absorbs light at one wavelength and re-emits that light at a different wavelength, Penn State physics and material science Professor Mauricio Terrones said.

The "monolayer" of tungstenite and sulphur atoms photoluminesce at room temperature, he said, so "no special temperature requirements are needed for the material to exhibit this property."

The researchers said the material has many potential applications in the fields of optical light detection, the production of light-emitting diodes, and even laser technology.

"The images of the photoluminescence are beautiful; the triangles light up all around their edges like little holiday ornaments -- holiday ornaments with potentially transformative, long-term applications in nano-optics," study co-author Vincent H. Crespi said.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Nutrients and Energy from Waste Liquid Manure Using Vibrating Cup Mill in a Tungsten Carbide Grinding

- Details

- Category: Tungsten Patents

- Published on Monday, 04 February 2013 15:04

Introduction - Uses for Liquid Manure

Liquid manure is a waste product naturally generated from mass animal farming. The disposal of liquid manure is a costly process and challenges the concept of recycling management. However, liquid manure can be directly distributed on fields or utilized in biogas plants.

Moreover, the residual solids released from biogas facilities can be also be directly utilized as fertilizers on fields. The presence of magnesium, potassium, phosphorous, and nitrogen makes liquid manure suitable for these applications.

However, liquid manure also contains heavy metals, which are undesirable. Hence, it is necessary to analyze these contents. This article discusses the application of the Vibrating Cup Mill PULVERISETTE 9 from Fritsch to process samples down to analysis fineness.

Analyzing the Metal Content of Manure

At first, the liquid manure is dried at a temperature of 105 °C to produce cake. The resulting cake is then manually crushed and processed using the Vibrating Cup Mill PULVERISETTE 9 in a hard metal tungsten carbide grinding set running at ‘optimal speed’ for 10 seconds. The resulting powder is analytically fine and completely homogenous.

Magnesium, potassium and phosphorous are key nutrients for plants, while heavy metals determined in solids are interfering accompanying elements in accordance with the internal rules of analysis. Nitrogen is detected in the liquid phase.

Conclusion

The Vibrating Cup Mill is ideal for this purpose due to the shorter process duration and the need to clean only very few large parts. The deployment of hard metal tungsten carbide grinding tools excludes the falsification of the heavy metal contents.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Graphene and 2D Tungsten Disulfide Electrodes in Lithium-Ion Batteries

- Details

- Category: Tungsten Patents

- Published on Wednesday, 30 January 2013 09:12

In this Thought Leader interview, Dr. Gurpreet Singh from Kansas State University talks to Will Soutter about his work on using 2D nanomaterials such as graphene and tungsten disulfide for electrodes in rechargeable lithium ion batteries.

WS: Can you give us a brief introduction to your work with lithium-ion batteries?

GS: We started working on lithium-ion batteries about 3 years ago. Our primary focus has been on designing the anode (negative electrode) material that can deliver improved electrochemical capacity with reduce polarization losses and no chemical or mechanical degradation over long periods of time. I have two PhD students (Romil Bhandavat and Lamuel David) working on this project.

WS: Why did you choose to study graphene in battery applications?

GS: Our initial work focused on use of molecular precursor derived glass ceramics (such as silicon oxycarbide) as rechargeable battery anodes. These high temperature glasses are unique because of their nanodomain structure consisting of graphene-like carbon domains.

In order to develop these anodes with tailored properties, we thought of first concentrating on understanding Li-ion storage mechanisms in single and multilayered graphene films. And that’s what got us into graphene film based anodes.

WS: How does the graphene manufacturing process you have developed make graphene more viable as a commercial electrode material?

GS: The process that we have developed allows synthesis of few-layer graphene without the use of high vacuum. The total time required for making these films is approximately 20 to 30 minutes. These graphene films can be used for corrosion prevention (grown on copper) and anodes for microbatteries (grown on nickel foil).

WS: What effects make graphene grown on nickel so much more effective than graphene grown on copper?

GS: We believe that sheets of graphene on nickel are relatively thick near the grain boundaries, and based on electron microscopy and spectroscopy data, these sheets are stacked in a well-defined manner called Bernal Stacking, which provides multiple sites for easy uptake and release of lithium ions as the cell is discharged and charged.

WS: How does the performance of your graphene electrodes compare to that of conventional electrode materials in lithium batteries?

GS: The purpose of this work was to study the underlying principles related to insertion and release of Li within individual sheets of few-layer graphene. A typical Li-ion battery anode is made from of a type of graphite slurry (along with conducting agent and binders) coated on a copper foil (current collector), and so a direct comparison with our graphene-based anode may not really be fair.

One clear advantage with graphene/Ni electrode is that it is less prone to delamination and does not require any binding or conducting agents (thereby saving weight). Flexible electrodes for microscale batteries are also possible with our graphene/Ni electrode.

WS: You have also published work on tungsten disulfide, another 2D nanomaterial – how do the properties of this material differ from graphene?

GS: Tungsten disulfide (and also molybdenum disulfide) has a similar layered morphology to graphene, but its physical and chemical properties are quite different.

Firstly, each layer in Tungsten disulfide is 3 atoms thick (1 tungsten sandwiched between 2 sulfur atoms), while graphene is a one atom thick layer of carbon.

Secondly, tungsten disulfide is a semi-conductor whilst graphene is an excellent conductor of electricity. Tungsten disulfide is also much heavier and denser.

Now these materials can be combined together in the form of heterostructures and/ or layered composites to unravel some interesting applications - for example, the vertical field effect transistor demonstrated by Nobel Prize winning team of Novoselov and Geim in a recent article.

WS: How does tungsten disulfide differ from graphene when used as an electrode material?

GS: Although both these materials allow uptake and release of Li when used as anodes (approx. 0 to 3 V versus Li/Li+ range), the chemistry is quite different. Li-atoms in graphene or graphite are believed to be stored by means of intercalation - in other words the atoms are physically inserted in between the sheets (approx. one Li atom per six carbon atoms, in a one electron process).

In the case of tungsten disulfide, the majority of the Li-atoms are believed to be stored by means of a chemical conversion reaction, in which Li reacts with tungsten disulfide sheets, dissociating them into tungsten and lithium sulfide nanodomains as the cell is discharged.

Upon charging, after the Li-ions have travelled back to the cathode, nanodomains of tungsten disulfide (approx. 3 to 5 nanometers) are formed at the anode (2 or more electrons get transferred per W atom).

Due to this intrinsic nanodomain structure that is formed after the first cycle, the kinetics of Li-ion transport in the tungsten disulfide anode become slower. Researchers are still trying to get a complete picture of these processes. Prof. C.M. Julien (Université Pierre et Marie Curie), in particular has made some important contributions in the area.

WS: How commercially viable is the fabrication process for tungsten disulfide sheets?

GS: I think this process should be commercially viable in the next few years. At the moment we are trying to optimize the process to get sheets with controlled shape, size and thickness without causing significant damage from interaction with the strong acid.

WS: Do you think we will see these materials in next-generation lithium-ion batteries? How far away is the technology from large-scale commercial applications?

GS: Absolutely. Although it is more likely that we will see graphene-based composites as battery electrodes, where graphene provides both the electrical conductivity and the mechanical flexibility required to reduce the fatigue associated with repeated insertion and extraction of Li-ions. Electrodes based on conversion chemistry are still in their early stages.

As far as large scale commercial applications are concerned, a lot of studies regarding long-term cycleability and safety of these batteries need to be performed. Insufficient testing or safety measures can lead to disasters similar to the one that lead to grounding of the Boeing 787 Dreamliner.

Professor Jeff Dahn at University of Dalhousie is leading the effort in large scale testing of Li-ion batteries.

WS: What areas will you be working on next? Are there any other promising nanomaterials you are exploring?

GS: We will continue to work on graphene and transition metal dichalcogenide film based anodes. In addition, we are also looking at combining the high thermodynamic stability of molecularly derived ceramics with graphene in order to prepare anodes that can withstand extreme abuse particularly when the cell is charged and discharge at extremely high current densities (or C-rates).

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Configurator Helps Engineers Match Thyristors to Different Machine Loads

- Details

- Category: Tungsten Patents

- Published on Tuesday, 29 January 2013 11:26

CD Automation's newly launched Application product selector effectively cross-tabulates different single and three-phase machine loads from 30A to 2700A for a comprehensive range of thyristor power controllers. The simplicity of the form presented to engineers hides the complexity of algorithms and processes, which combine to provide an optimal load configuration.

First, using drop-down menus throughout, the engineer enters his choice from the application and element type: normal resistance elements; variable resistance with temperature using elements including molybdenum, platinum, quartz lamp, and super Kanthal among others; and transformer coupled with elements from graphite through short wave infrared to inductive loading.

Next, if selecting a transformer coupled with tungsten elements for example, the engineer can select the load configuration from single, three-phase star with or without neutral, three-phase delta and three-phase open delta. The next field is for the number of phases controlled, followed by fields for 'input-control signal', 'firing mode' and 'required current (A)'. On the above configuration, selecting three phases and DC linear will offer up a choice of three firing modes: burst firing, single cycle or phase angle.

The matching CD Automation thyristor products are then displayed below the form, and in the case of the transformer coupled with tungsten elements mentioned above, would show the REVO-E three-phase thyristor power controller up to 600A (14 current sizes available) and the Multidrive to 2700A (in 20 current sizes). The product selector is for guidance only and the engineer is encouraged to contact CD Automation to confirm this is the correct configuration.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Spherical Tungsten Disulfide Powder

- Details

- Category: Tungsten Patents

- Published on Friday, 25 January 2013 14:17

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten interconnect method

- Details

- Category: Tungsten Patents

- Published on Friday, 25 January 2013 14:07

A tungsten gate electrode and method of fabricating the same are provided. In one aspect, a method of fabricating a circuit device in an opening in an insulating film on a substrate is provided. The method includes depositing a film of amorphous silicon and amorphous tungsten in the opening, and thereafter depositing a film of polycrystalline tungsten on the film and annealing the substrate to react the amorphous silicon with the amorphous tungsten to form tungsten silicide on the insulating film and to increase the grain structure of the polycrystalline tungsten film. The tungsten silicide film and the polycrystalline tungsten film may be planarized to the insulating film. The method enables the seamless fabrication of an adhesion layer and a tungsten conductor structure in a single chamber and without resort to titanium.

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Carbide Blades Mean Faster Steel

- Details

- Category: Tungsten Patents

- Published on Thursday, 24 January 2013 15:13

New bandsaws using carbide tipped blades mean that Carrs Toolsteel Technologies can supply a single round or flat section billet to a customer within 24 hours.

The lead-time for multiple tool steel billets now is one to two days. Previously, two to three days was the typical delivery time for all such orders.

The two new Kasto bandsaws are the first ones installed at Carrs, Tipton site to have the necessary rigidity to operate with the tungsten carbide tipped (TCT) blades.

Conventional bimetal types have been retained for some cutting while carbide trials continue.

The other new bandsaw is a KASTOevo A4x5, capable of cutting round stock up to 430 mm diameter. Carrs is looking to increase this side of its business, as it currently forms only around 30 per cent of its billet throughput, the remainder being flat section. Again, TCT blades are used to very productive effect on this smaller machine.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Audi LED Lighting Technology - Xenon Plus-Headlights

- Details

- Category: Tungsten Patents

- Published on Thursday, 24 January 2013 13:59

Whether xenon plus or LED – the headlights and taillights in Audi models make a strong statement. The brand’s lighting technologies combine their attractive effects with a high level of active safety – with adaptive light, today’s headlights already react to the environment and to other vehicles in traffic.

Xenon plus headlights are offered in all models of the Audi lineup, either as optional or standard equipment. Xenon headlights are gas discharge lamps. Two tungsten electrodes are fused in a quartz glass cylinder, known as the burner, and a concentrated light arc burns between. The xenon inert gas charge in the burner, which is pressurized up to 100 bar, gives off a slightly violet light, while metallic salts in the glass cylinder charge reduce its color temperature to the spectrum of daylight.

Xenon headlights provide a much brighter light and better illumination than halogen headlights with incandescent bulbs, their energy consumption is about 20 percent lower and they have much longer life. In xenon plus technology from Audi, a single burner generates both the low and high beam lights, and they are switched by a moveable shutter. Of course, all xenon headlights are mercury-free.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

High-Torque Screen Classifying Cutter

- Details

- Category: Tungsten Patents

- Published on Thursday, 24 January 2013 11:48

New high-torque, low-speed cutter reduces hard materials and friable products into controlled particle sizes.

The SCC-15-SS Screen Classifying Cutter from Munson Machinery Company, Inc. features a proprietary rotor design comprised of cutter bits attached to a helical array of staggered holders called “interconnected parallelograms,” that continuously cut and crush oversize materials against twin, stationary bed knives.

Unlike high-shear cutters that rotate at high speeds, the high-torque cutter is equipped with a direct-coupled, gear-reduced drive that rotates the shaft at speeds down to 10 RPM to cut or crush tough materials using low shear, and/or to minimize fines when cutting friable materials.

The cutter bits, which are available in stainless steel, tool steel and tungsten carbide, can be slid onto holders and secured with one retaining socket-head screw, allowing rapid replacement.

Applications include a diversity of chemical, mineral, foundry and plastics materials.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Deposition of tungsten nitride

- Details

- Category: Tungsten Patents

- Published on Wednesday, 23 January 2013 09:29

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com