Benefication Methods of Scheelite Tailings

- Details

- Category: Tungsten Patents

- Published on Thursday, 07 March 2013 10:35

Brief description of this technology:

The present invention provides a beneficiation methods of scheelite tailings .Turning scheelite tailings tune into tungsten slurry and added dispersant to the tungsten slurry ; then configure reunion reagents and reunion reagent was added to the tungsten slurry; Finally, Separation of the tungsten slurry. The reunion of the configuration of the reagent is tune into the first corn starch, corn starch slurry, and then adding a composite of cerium ammonium nitrate and potassium persulfate initiator, add oleic acid after stirring. It forms water soluble flocculant, and finally added anhydrous ethanol to the water-soluble flocculantr , ethanol extract after filtration reunion reagent. The present invention of scheelite tailings beneficiation method, through the reunion reagents multiple tungsten ore particles agglomerate into larger particles of tungsten ore group, and then placed on the sorting belt sorter. This method can improve the recovery rate and taste of tungsten ore.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Antioxidant Tungsten Rhenium Thermocouples

- Details

- Category: Tungsten Patents

- Published on Thursday, 07 March 2013 09:53

Technical description:

Temperature measurement is the eyes of the industrial production and scientific research. However, this high temperature measurement, particularly the automatic control of high temperature, still is the expensive platinum-rhodium thermocouple .Conventional tungsten rhenium thermocouple is capable of measuring high temperatures,but that can not be used in an oxidizing atmosphere. This patent takes use of the double protection tube and the perfect combination of special packing structure and the outer and inner layers of .It can prevent oxidation of the high-temperature process of using osmotic mini,at the same time eliminate residual oxygen packing microporous and silk gap.So that can ensure the long-term use of tungsten-rhenium thermocouples in the oxidation of the atmosphere . While using the structure and techniques of this patent, we useboth inside and outside protective tube of different materials and different fillers.In this way it can widen the range of applications of the tungsten-rhenium thermocouple extending from the ultra-high temperature to the high temperature,from the general medium to the special medium. This method not only can partially replace the platinum rhodium thermocouple, but also can be applied to special areas which some of the platinum-rhodium thermocouple are unbearable.

Prospects for applications of the technology:

The patented technology is the main part of measuring high temperature. In the high temperature zone it can replace the expensive platinum-rhodium thermocouple. In ultra-high temperature zone it is NO.1. Its products can be widely used in metallurgy, machinery, chemical industry, light industry, electric power, petroleum, aerospace, and cement ceramic silicate industrial sector, the market prospect is so broad.

The analysis of economic benefit :

This patented technology uses raw materials and equipment in the existing markets, require minimal equipment and don not have waste emissions. This patent is especially suitable for the existing thermal instrumentation manufacturers. Initial investment can be only a few million. If it is estimatedf from the market share of a few percent , there are several million dollars of annual profit margins.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The Chemical Granulation Technology of Calcium Tungsten

- Details

- Category: Tungsten Patents

- Published on Wednesday, 06 March 2013 18:03

The shape of the general chemical synthesis calcium tungsten is amorphous powder. Because powdery is sticky, controlled feeding can not be accurately measured, and therefore it is more difficult in the application. Measurement of granular calcium tungsten is accurate, and feeding applications are so extensive . The present invention is a new technology by using chemical methods to manufacture calcium tungsten. Chemical synthesis, could be produced mainly through the control of the mother liquor PH to complete 5-7 microns of chemical calcium tungsten particles and calcium tungsten can be widely applied to the process of feeding of calcium tungsten. This product was welcomed by foreign businessmen in the 1979 Fair trading.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The Beneficiation Process of Molybdenum and Tungsten Oxide

- Details

- Category: Tungsten Patents

- Published on Wednesday, 06 March 2013 17:13

The invention discloses a kind of beneficiation process molybdenum-tungsten oxide. This process as follows: the degree of ore crushing monomer solution dissociation is ≥ 70%; preferential flotation molybdenum disulfide; sorting after flotation tailings grading sediment, sediment systemalkali to adjust the agent, sodium silicate inhibitor, emulsified fatty acids collector, the mixed sediment sorting rough concentrate Featured, molybdenum and tungsten oxide ore mixed concentrate. The mixed concentrate regrinding join inhibitor, selected secondary concentrates; the secondary concentrates Petrov method selected, scheelite and molybdenum oxide, tungsten ore dressing concentrate.

This invention has the following advantages: 1. The invention discloses a process of molybdenum and tungsten oxide ore beneficiation process;

2. The invention solves the problem of low technology indicators of molybdenum tungsten oxide;

3. The invention is to complete the study of laboratory tests, and complete the implementation of the industrialization at first time in domestic.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Diffusion Welding Methods of Tungsten Alloy and Tantalum Alloy in Low Temperature

- Details

- Category: Tungsten Patents

- Published on Wednesday, 06 March 2013 16:37

The invention relates to a tungsten alloy and tantalum alloys cryogenic diffusion welding method, the steps of this method include: (1) the cleaning steps of workpiece surface: tungsten alloy, tantalum alloy processed to a predetermined size, and to be welded to remove them and the intermediate layer - nickel foil surface oxide layer;

(2)the steps of workpiece assembly : the middle layer - nickel foil placed between the tungsten alloy and tantalum alloy structure is welded to the workpiece;

(3)the steps of vacuum diffusion welding: put welded workpiece into the vacuum diffusion welding furnace, heating, insulation. At the beginning of the insulation axial pressure is applied to the workpiece. At the end of insulation, we should remove pressure and cool in the furnace.

The problem of the present invention is able to overcome that the existing welding techniques can not be achieved at a low temperature of tungsten alloys and tantalum alloys high quality diffusion welding. This invention is particularly suitable for reliable and precision at low temperatures of the diffusion welding between the tungsten alloys and tantalum alloys. The tungsten tantalum welded body can be used to in the fields of high-pressure physics and nuclear fusion research.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The Wastewater Treatment Method of Containing Tungsten During Melting Tungsten

- Details

- Category: Tungsten Patents

- Published on Wednesday, 06 March 2013 15:28

The wastewater treatment method of containing tungsten during melting tungsten is a method of industrial wastewater treatment. This provides us a simple, low cost, high metal recovery rate method of wastewater treatment. After the exchange of ion, wastewater containing tungsten during melting tungsten is pretreated. After the pretreatment of the wastewater containing tungsten in tungsten smelting, we will collect chemical precipitation. And we should use chemical precipitation recycle tungsten in wastewater containing tungsten. That can optimize the industrial process, make a short industrial process. At the same time, it can reduce the quantity of consumed materials. This method not only improves the recovery rate of WO3, but also reduce the pollution to the environment. It is easy to monitor and control all kinds of indicators and male the production process cleaner.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The Method of Processing High Alkali Concentration of Sodium Tungsten Solution

- Details

- Category: Tungsten Patents

- Published on Wednesday, 06 March 2013 14:21

The method of processing high alkali concentration of sodium tungsten solution is to use strongly alkaline anion exchange resin. When dealing with high concentration of alkali solution, we just desorb for saturated resin. The characteristic is using multiple fixed beds exchange column in series, and take series of column operations. The exchange column of A leaks after wearing and containing tungsten exchange liquid directly into column B. It continues to adsorption. Column B leaks after wearing again further to column C. Column C leaks after wearing again further to column D. It is an order of pushing downstream. When column saturated, we can desorb and regenerate of resin at the same time. The regeneration of column A connected to the downstream. It is always continuing cycle operation.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The Method for Scheelite Oxide

- Details

- Category: Tungsten Patents

- Published on Wednesday, 06 March 2013 13:29

This invention uses the method of combusting urea to manufacture scheelite oxide. This method, which is to mix nitrate, ammonium salt with combustion urea according to the quality of a certain number of moles is combusting. It can be made into a series of high purity scheelite oxide solid and solution powder that keep a certain period of time to natural cooling. Ammonium salt should be ammonium molybdate or ammonium paratungstate. Nitrate should be the nitrate of Mg, Ca, Sr, Ba, Cr, Mn, Co, Ni, Zn, Cd or Al and nitrate, ammonium molybdate and urea combustion have reaction. The nitrate of Mg, Ca, Sr, Ba, Mn, Co, Ni, Zn or Cd ,ammonium paratungstate and urea combustion have reaction. The number of moles of urea is as 4 ~ 5 times as the total number of moles of ammonium salt and molybdenum ion or tungsten ion. The temperature of combusting is 400 ~ 500 ℃; the time of holding is during 20 ~ 30 min. This method is not only very simple during operating process, short preparation time, low energy consumption, but also particularly suitable for industrial mass production.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Rare Mineral Called Tungstenite Yields Light-Emitting Nano Triangles

- Details

- Category: Tungsten Patents

- Published on Thursday, 07 February 2013 11:04

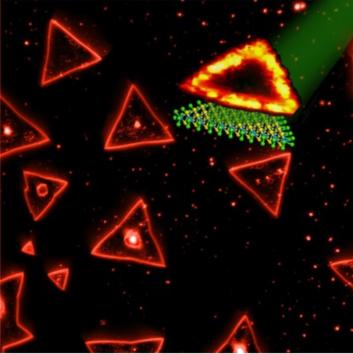

Triangular single layers of tungsten disulfide have been synthesized by Penn State researchers. The edges of the triangles exhibit extraordinary photoluminescence, while the interior area does not. The photoluminescent signal disappears as the number of layers increases. Courtesy of Terrones lab, Penn State University.

A rare mineral called tungstenite formed into single sheets has yielded triangular structures with unusual light-emitting properties that could be used in optical technologies such as light detectors or lasers.

Creating single, one-atom-thick layers, or monolayers, is of interest to scientists because the chemical properties of minerals and other substances are known to change depending on their atomic thickness, which could enable applications of multilayered materials of various thicknesses. In previous research, scientists at Penn State reached the similar goal of creating monolayers of graphene, although the process was difficult.

“The technique these researchers used was tedious, but it worked,” said Mauricio Terrones, a professor of physics and of materials science and engineering at Penn State University. “They basically removed, or exfoliated, the graphene, layer by layer, with Scotch tape, until they got down to a single atom of thickness.”

Terrones and colleagues have now used a controlled thermal reduction-sulfurization method called chemical vapor deposition to accomplish the same feat with a rare mineral called tungstenite. After depositing crystals of tungsten oxide less than 1 nm in height, they passed the crystals through sulfur vapor at 850 °C. This process yielded single sheets of a one-atom-thick structure called tungsten disulfide — a honeycomb pattern of triangles consisting of tungsten atoms bonded with sulfur atoms. This monolayer has unusual light-emitting, or photoluminescent, properties.

“One of the most exciting properties of the tungsten disulfide monolayer is its photoluminescence,” Terrones said. Photoluminescence occurs when a substance absorbs light at one wavelength and re-emits that light at a different wavelength. It also occurs in certain bioluminescent animals such as angler fish and fireflies.

“One interesting discovery from our work is the fact that we see the strongest photoluminescence at the edges of the triangles, right where the chemistry of the atoms changes, with much less photoluminescence occurring in the center of the triangles,” he said.

The monolayer also luminesces at room temperature, so “no special temperature requirements are needed for the material to exhibit this property,” Terrones said.

"The images of the photoluminescence are beautiful; the triangles light up all around their edges like little holiday ornaments — holiday ornaments with potentially transformative, long-term applications in nano-optics," said Vincent H. Crespi, co-author and distinguished professor of physics, chemistry and materials science and engineering at Penn State.

The structure has many potential applications in the fields of optical light detection, LED production and even laser technology. The scientists plan to use the chemical vapor deposition technology to produce layered materials using monolayers of other materials.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Light-Emitting Triangles Called Tungstenite Have Potential Applications

- Details

- Category: Tungsten Patents

- Published on Wednesday, 06 February 2013 10:56

Scientists have created single layers of a naturally occurring rare mineral called tungstenite, or WS2. The resulting sheet of stacked sulphur and tungsten atoms forms a honeycomb pattern of triangles that have been shown to have unusual light-emitting, or photoluminescent, properties.

According to team leader Mauricio Terrones, a professor of physics and of materials science and engineering at Penn State, the triangular structures have potential applications in optical technology; for example, for use in light detectors and lasers. The results of the research will be published in a print edition of the journal NANO Letters.

Terrones explained that creating monolayers -- single, one-atom-thick layers -- is of special interest to scientists because the chemical properties of minerals and other substances are known to change depending on their atomic thickness, opening the door to potentially useful applications of multi-layered materials of various thicknesses. In previous research, scientists had accomplished the feat of making a monolayer of graphene -- a substance similar to the graphite found in pencil leads. "The technique these researchers used was tedious, but it worked," Terrones said. "They basically removed, or exfoliated, the graphene, layer by layer, with Scotch tape, until they got down to a single atom of thickness."

Now, for the first time, Terrones and his team have used a controlled thermal reduction-sulfurization method -- or chemical vapour deposition -- to accomplish the same feat with a rare mineral called tungstenite. The scientists began by depositing tiny crystals of tungsten oxide, which are less than one nanometer in height, and they then passed the crystals through sulphur vapour at 850 degrees Celsius. This process led to individual layers -- or sheets -- composed of one atom in thickness. The resulting structure -- called tungsten disulphide -- is a honeycomb pattern of triangles consisting of tungsten atoms bonded with sulphur atoms.

"One of the most exciting properties of the tungsten disulphide monolayer is its photoluminescence," Terrones said. Terrones explained that photoluminescence occurs when a substance absorbs light at one wavelength and re-emits that light at a different wavelength. The property of photoluminescence also occurs in certain bioluminescenent animals such as angler fish and fireflies. "One interesting discovery from our work is the fact that we see the strongest photoluminescence at the edges of the triangles, right where the chemistry of the atoms changes, with much less photoluminescence occurring in the centre of the triangles," Terrones said. "We also have found that these new monolayers luminesce at room temperature. So no special temperature requirements are needed for the material to exhibit this property."

Co-author Vincent H. Crespi, Distinguished Professor of Physics, Chemistry, and Materials Science and Engineering at Penn State, added, "The images of the photoluminescence are beautiful; the triangles light up all around their edges like little holiday ornaments -- holiday ornaments with potentially transformative, long-term applications in nano-optics."

The research has many potential applications in the fields of optical light detection, the production of light-emitting diodes, and even laser technology. The researchers also plan to try the chemical-vapour-deposition technology to grow innovative monolayers using other layered materials with potentially useful applications.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com