Tungsten Carbide Coating & Hard Face Welding Benefits

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 19:01

- Hits: 250

The benefits related to tungsten carbide coating and hard face welding list as follow,

- Tools can be resurfaced not replaced

- Increased gripping power

- Carbide coating increases tool life

- Treatment cost a fraction of replacement tooling

- Decreases downtime

- Tungsten carbide coating surface hardness is up to 74 Rc

- Excellent uniformity

- No thermal distortion due to the low heat input process

- True metallurgical bond

- Carbide coating will not chip, peel or flake

- In most cases clamping pressure can be reduced

- Increase machining rates with additional gripping power

- Tools can be accurately masked off

- Increase or decrease the coefficient of friction

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How are Tungsten Carbide Parts Made

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 18:59

- Hits: 313

Before a finished tool or component can be made, typically a blank needs to be made. This is performed through a powder metallurgy and sintering process.

• Firstly a mould of the macro shape of the blank desired is made. This is made intentionally at a calculated larger size to accommodate the volumetric shrinkage (which can approach up to 50%) that will occur later in the sintering process.

• Powders are then prepared with an involved process of mixing and milling, paying attention to particle size and consistency, purity, quantity etc. This step has a significant effect on the “quality” of the overall blank produced.

• The prepared powders are then compacted into a solid “green” state blank with the use of high pressure press. The green blank can then be handled and to some degree additional processes such as turning, drilling and milling can be performed on the item before it is sintered.

• The green parts are then put through a process of pre-sintering, sintering and Hot Isostatic Pressing (if specified) to remove the binder waxes, liquefy the binder and fully densify the cemented carbide. Shrinkage occurs during this process.

• The fully dense tungsten carbide blank may then be further finished by grinding, EDM wire cutting, or diamond polishing. For the most demanding high volume and hardest working production tools, tungsten carbide is a superior base material.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbides Coatings Layer Structural

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 18:57

- Hits: 248

Hard coatings of tungsten carbides have been obtained by the deposition of tungsten thin layers, on steel substrates (containing 0.7% wt. carbon), according to the cathodic magnetron sputtering held at temperature of 500°C. It is established by X-rays diffraction that, in the temperature range 500-800°C, no formation of tungsten carbides was observed. However, the annealing at a temperature greater than or equal to 900°C promotes the reaction between the constituents of the samples (W, Fe, C) and hence the formation of W2C carbide. No other compounds were detected. The micro-hardness measured by Vickers tests, increases with the rise in temperature, particularly from 900°C. The morphology of the surface samples depends on the temperature and duration of thermal annealing.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Nano-Structure of CVD Tungsten Carbide Coating Type

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 18:55

- Hits: 241

Nano-Structure of CVD tungsten carbide coating is a sophisticated nano-structured material comprising a metallic tungsten matrix with dispersed tungsten carbide nano-particles with a typical size range of 1-10 nm.

This coating type increases abrasion resistance up to tweleve fold higher than that of hard chrome and improved hardness of more than 1100 Hv. The coating can be formed on titanium, low alloy and some tool steels, stainless steel, and Ni-, Co- and Cu-based alloys. This nano-structured material shown unprecedented impact resistance, crack resistance and toughness by tolerating 3000 microstrain deformations without any deterioration.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

CVD Tungsten Carbide Coatings Application

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 18:53

- Hits: 255

CVD tungsten carbide coating is suitable for applications with many different components operating in extreme erosive and abrasive atmospheres, such as critical components of metal seated ball valves, downhole tools, and pumps handling abrasive fluids.

Ball valves coated with CVD tungsten carbide coating, demonstrate increased valve life thanks to the coating as it make them scratch-proof and able to resist erosion and abrasion.

CVD tungsten carbide coating extends the life and reduces downtime costs of downhole tools such as grippers for down-hole tractors, high loading bearings pins, and mud-driven hydraulic parts for directional drilling tools.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

CVD Tungsten Carbide Coatings Main Characteristics

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 18:51

- Hits: 289

CVD tungsten carbide coatings are different from other tungsten carbide coatings as they do not use cobalt or nickel metal matrix binder, the main characteristics of CVD tungsten carbide coatings are including,

- Outstanding chemical and corrosion resistance

- Free from through porosity, thus effectively protecting mild steel substrate from corrosive media without sealing the coating

- Superior resistance to sulfide stress cracking

- Provides effective protection against mineral acids such as sulfuric acid and hydrochloric acid

- Resists Aqua Regia at room temperature

- Superior wear resistance; Wear rate of CVD tungsten carbide coatings is four fold lower when compared to thermal spray WC, 12 fold lower than hard chrome, and 40 fold lower when compared to abrasion resistant steel AR-500

- Demonstrates better erosion rate when compared to chrome carbide weld overlay, hard chrome, white iron, cemented carbide, and various other hard materials

- Better fatigue resistance and toughness

- Superior resistance to impact and deformations

- Deposition from the gas phase enables coating of internal surfaces and intricate shapes

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide and Tantalum Carbide Coatings on Machining Tools

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 18:42

- Hits: 242

High speed steel tools for machining were coated with WC and TaC by chemical vapor deposition (CVD), 25 and were used in a high speed milling machine. The physical integrity of the tools coatings were analyzed by scanning electron microscopy at the end of the trials and materials surface roughness were compare in order to predict best behaviour too. The relevant analyses indicate that the deposits form heterogeneous films. The results suggests that the TaC coating resist higher attrition than made of WC's.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Direct Hydrothermal Precipitation of Pyrochlore-Type Tungsten Trioxide Hemihydrate

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 16:24

- Hits: 290

Pyrochlore-type tungsten trioxide hemihydrate (WO3·0.5H2O) powder with the average particle size of 0.5μm was prepared successfully from the weak alkaline sodium tungstate solution by using organic substances of sucrose or cisbutenedioic acid as the acidification agent. The influences of solution pH and acidification agents on the precipitation process were investigated. The results showed that organic acidification agents such as sucrose and cisbutenedioic acid could improve the precipitation of pyrochlore WO3·0.5H2O greatly from sodium tungstate solution compared with the traditional acidification agent of hydrochloric acid. In addition, the pH value of the hydrothermal system played a critical role in the precipitation process of WO3·0.5H2O, and WO3·0.5H2O precipitation mainly occured in the pH range of 7.0 to 8.5. The precipitation rate of tungsten species in the sodium tungstate solution could reach up to 98 pct under the optimized hydrothermal conditions. This article proposed also the hydrothermal precipitation mechanism of WO3·0.5H2O from the weak alkaline sodium tungstate solution. The novel method reported in this study has a great potential to improve the efficiency of advanced tungsten trioxide-based functional material preparation, as well as for the pollution-reducing and energy-saving tungsten extractive metallurgy.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pyrochlore-type tungsten oxide structure

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 15:46

- Hits: 294

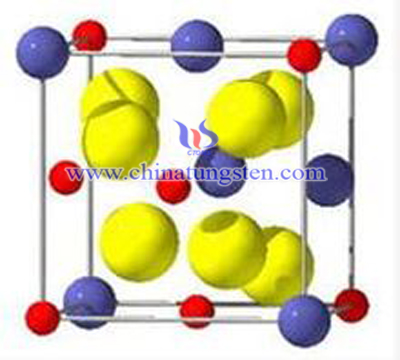

Pyrochlore type tungsten oxide (often referred to as H2W2O7 or WO3 • 0.5H2O) A vacancy is a layered perovskite-based oxide, due to the molecular sieve having a mesh structure and dielectric stability, and in catalysis, sensing, electrical photochromic, fuel cells and other areas showed a wide range of applications. Further, the tungsten oxide powder pyrochlore type after concentrated hydrochloric acid Na element can be efficiently removed, and after firing can be directly obtained WO3, tungsten industry is expected to be novel intermediates.

Pyrochlore type WO6 tungsten oxide is distorted octahedral structural motifs, by the angle of the top of the tungsten oxide rigid skeleton to build a layered structure with a six-membered ring channels, it has a three-dimensional channel, this channel is conducive to the rapid migration of cations and exchange. Wherein a water molecule is formed directly in contact with the two-dimensional layer structure of tungsten by hydrogen bonding interactions between the layers. Standard stoichiometric H2W2O7 cubic crystal lattice parameters a = 10.305 (3), Z = 16. On the thermal stability is concerned, at temperatures above 320 ℃, tungsten oxide pyrochlore-type structure is destroyed, i.e. WO6 octahedron structural motifs, by angular tungsten oxide build from the top of a rigid skeleton having a six-membered ring pore network structure collapsed, forming a quadrature type of tungsten oxide.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pyrochlore Type Oxide Reaction Mechanism

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 April 2015 15:45

- Hits: 290

Pyrochlore type oxide, tungsten oxide (often referred to as H2W2O7 or WO • -0.5H2O) to WO6 distorted octahedral structural motifs, by a rigid skeleton top corner WO6 construct a layered structure with the bore having a six-membered ring, in layers formed between road. Which has an n-type semiconductor properties and microwave absorption properties, as a new industrial materials, it photochromic, electrochromic, gas discoloration caused by aspects, catalysis have a very important significance. In addition, the tungsten oxide pyrochlore type after the firing energy directly into tungsten trioxide, tungsten trioxide can be prepared as intermediates.

Currently preparation of tungsten oxide pyrochlore type used mainly soft chemical synthesis method and hydrothermal synthesis. Hydrothermal synthesis method is widely applied in the field of inorganic materials synthesis, the advantage of easy-to-control hydrothermal conditions, the resulting product of high purity, good dispersion, size and easy to control. Currently Hydrothermal Synthesis of tungsten oxide pyrochlore type usually sodium tungstate solution for raw materials, hydrothermal reaction after acidification some time to prepare. According to the findings of the different researchers, sodium tungstate solution pH in the range of 2.0 to 8.9 can hydrothermal synthesis of tungsten oxide pyrochlore type, but its synthesis mechanism is not clear, no direct evidence to determine the reaction precursor, study needs further. The presence of an acidic environment with a variety of tungsten ions and more heteropolyacid ion, and the transformation of the structure of the situation is complex and varied, this article focuses on the basic system of tungsten oxide pyrochlore-type hydrothermal synthesis mechanism.

Pure sodium tungstate solution for the reactants, hydrochloric acid as an additive, in an alkaline environment pyrochlore type hydrothermal synthesis of tungsten oxide. Use FT-IR analysis of the infrared spectra of the test method change under different rules and acidification of the reaction solution Na2WO4 different time period, to analyze WO2-4, W7O6-24, H2W12O10-42 and W2O2-7 whether to prepare tungsten oxide pyrochlore-type reaction precursors, ruled out the use of exclusion H2W12O10-42, W2O2-7 possibility before the reaction the body as that of the precursor should WO2-4 and W7O6-24, and assisted by thermodynamic calculations prove.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com