How to Choose the Size of Lanthanum Tungsten Electrode According to the Application?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:17

- Hits: 108

Tungsten inert gas welding (TIG) and plasma welding, the choice of electrode material plays a decisive role in the welding quality. With the widespread application of environmentally friendly materials, lanthanum tungsten electrode has gradually become an important choice in the welding industry.

Which Welding Current Range Is Suitable for Lanthanum Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:13

- Hits: 129

In modern welding processes, the correct current setting plays a crucial role in weld quality.

Is the Lanthanum Tungsten Electrode Suitable for Direct Current or Alternating Current?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:11

- Hits: 118

With the widespread use of argon arc welding (TIG) technology today, the type of welding power source—direct current (DC) or alternating current (AC) —has a direct impact on welding process stability, material compatibility, and welding efficiency. Electrode material, a key component of the welding process, and its compatibility with the power source are fundamental to weld quality.

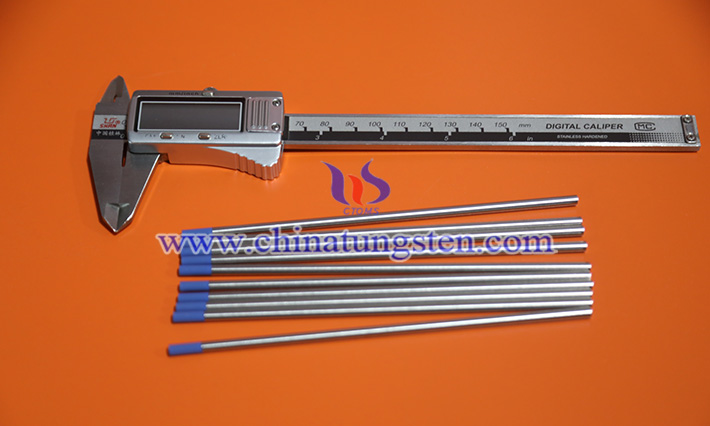

How to Distinguish the Color-Coded of Lanthanum Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:08

- Hits: 115

In the welding industry, tungsten electrodes, a key material in precision processes like argon arc welding (TIG), play a crucial role in arc generation, stable electrical conductivity, and heat conduction. With the advancement of materials processing, welding alloys doped with rare earth elements have gradually replaced traditional products containing radioactive components.

How Does Different Lanthanum Contents Affect Tungsten Electrode Performance?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:06

- Hits: 116

In modern welding technology, the choice of electrode material directly impacts welding quality, efficiency, and equipment stability. As a key consumable widely used in TIG (tungsten inert gas arc welding) and plasma cutting, tungsten electrodes, due to their high melting point, excellent conductivity, and ablation resistance, have become a vital component in industrial manufacturing.

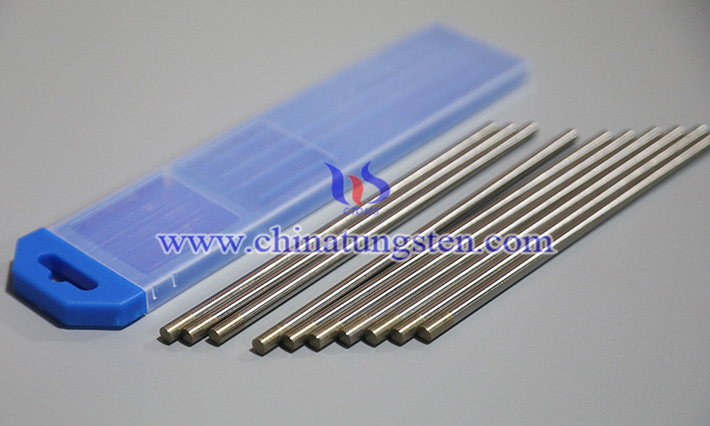

What Are the Common Types of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:03

- Hits: 125

In modern welding, tungsten-based welding materials doped with the rare earth element lanthanum have become an indispensable electrode material in industrial manufacturing due to their excellent arc starting performance and environmentally friendly properties.

What Is Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:00

- Hits: 113

In modern welding technology, non-consumable electrodes play an extremely important role in high-quality welding processes, especially in application scenarios such as tungsten inert gas welding (TIG), where the performance of electrode materials directly determines the stability, efficiency and quality of welding.

Application of Tungsten Alloy Counterweights in Sports Equipment

- Details

- Category: Tungsten Information

- Published on Monday, 28 July 2025 11:45

- Hits: 139

In the vast world of sports, from the rigorous training of professional athletes to the daily fitness routines of the general public, various sports equipment play a crucial role. Among these, there is a component often overlooked yet vital—the counterweight. Like an unsung hero behind the scenes, it silently contributes to the high-performance capabilities of sports equipment. For instance, in fitness dumbbells, improper counterweighting can not only affect workout effectiveness but also lead to injuries; similarly, in golf clubs, the right counterweight can enhance shot precision and power. Today, let’s delve into a standout counterweight material in the sports field—tungsten alloy counterweights.

Exploration of Tungsten Alloy Application Fields

- Details

- Category: Tungsten Information

- Published on Monday, 28 July 2025 11:35

- Hits: 135

In the vast field of materials science, high-density tungsten alloys stand out due to their unique properties, becoming a focal point across numerous industries. Tungsten alloy is a material with tungsten as the base (W content 85-99%) and small amounts of elements such as Ni, Cu, Co, Mo, and Cr added. Its density ranges from 16.5 to 18.75 g/cm³, more than double that of steel, making its remarkable high-density characteristic a key factor in its wide-ranging applications.

What Is Tungsten-Copper Contact?

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 July 2025 17:48

- Hits: 151

Tungsten-copper (WCu) contacts, like tungsten-silver (WAg) contacts, are highly representative types of tungsten contacts. The reason their physicochemical properties, production methods, and applications are largely similar lies in the fact that both are manufactured using the refractory metal tungsten as a base. However, there is a cost difference between silver and copper, with silver generally being more expensive than copper.

sales@chinatungsten.com

sales@chinatungsten.com