Impact of Carbon Element on Tungsten-Nickel-Iron Alloy Performance

- Details

- Category: Tungsten Information

- Published on Thursday, 10 July 2025 11:18

- Hits: 169

Although carbon is typically present in trace amounts in tungsten-nickel-iron alloy, its influence on alloy performance is significant. Carbon exhibits a "double-edged sword" effect: small amounts enhance strength and hardness through solid-solution strengthening and carbide dispersion strengthening, while excessive carbon reduces toughness and fatigue resistance due to brittle phase precipitation and interface weakening.

Impact of Oxygen on Tungsten-Nickel-Iron Alloy Performance

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 16:24

- Hits: 180

Oxygen is a critical factor in regulating the performance of tungsten-nickel-iron alloy. Through mechanisms such as oxide inclusion formation, solid-solution strengthening, and grain boundary segregation, it impacts the alloy’s mechanical properties, thermal stability, and processability. Therefore, in practical applications, oxygen content must be controlled within reasonable limits through raw material purification, process optimization, and deoxidation techniques to fully leverage the alloy’s advantages in high density, high strength, and excellent corrosion resistance.

Sources of Impurity Elements in Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 16:21

- Hits: 171

The impurity elements in tungsten-nickel-iron alloy (W-Ni-Fe) originate from complex sources, primarily involving raw materials, production processes, and environmental media.

Impurity Elements in Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 16:19

- Hits: 175

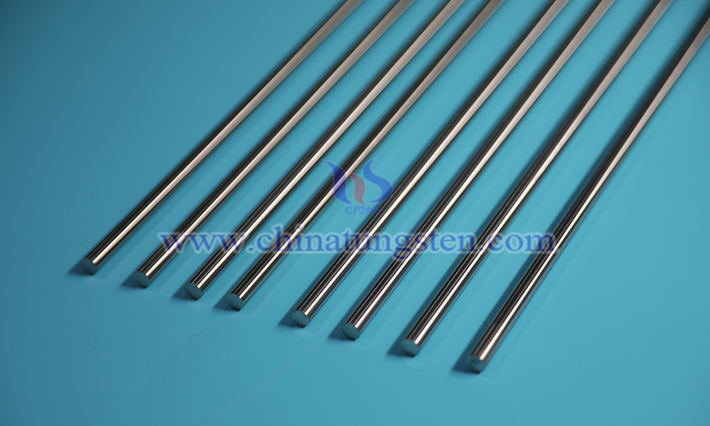

In addition to the primary elements tungsten, nickel, and iron, tungsten-nickel-iron alloy contains trace impurity elements such as hydrogen, oxygen, carbon, sulfur, and phosphorus. These impurities can compromise grain boundary integrity, form brittle phases, and reduce the alloy’s conductivity, high-temperature strength, and radiation resistance. Control is achieved through raw material purification and process optimization, such as vacuum sintering. The following outlines the impact of key impurity elements on alloy performance.

Impact of Hydrogen on Tungsten-Nickel-Iron Alloy Performance

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 16:17

- Hits: 176

Hydrogen’s influence on tungsten-nickel-iron alloy performance—through hydrogen embrittlement, conductivity degradation, and hydrogen retention—can reduce material reliability. However, controlling hydrogen content and enhancing performance can be achieved through alloy design and surface engineering.

Material Composition of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 16:15

- Hits: 159

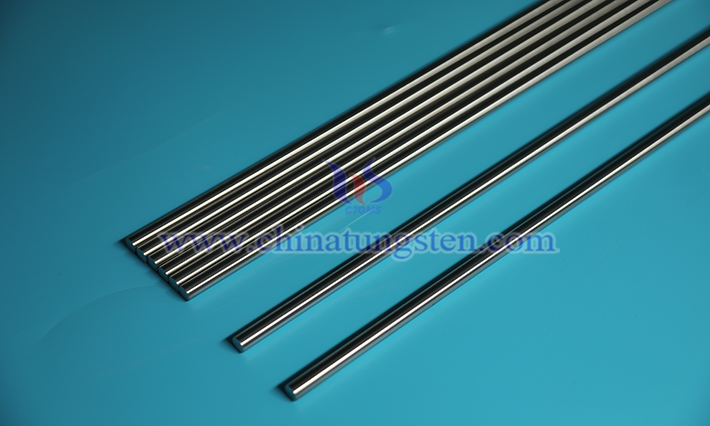

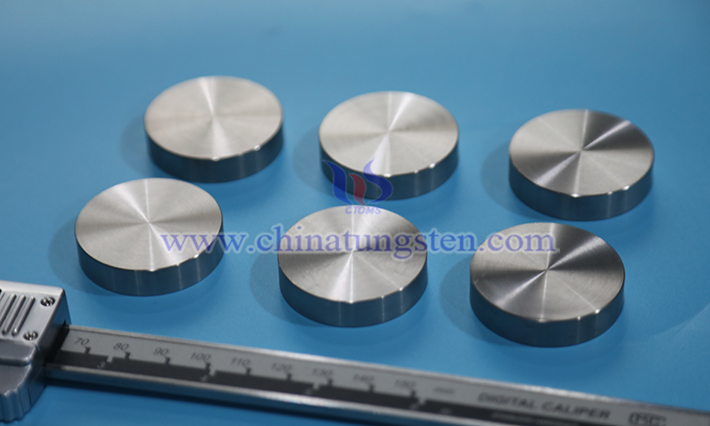

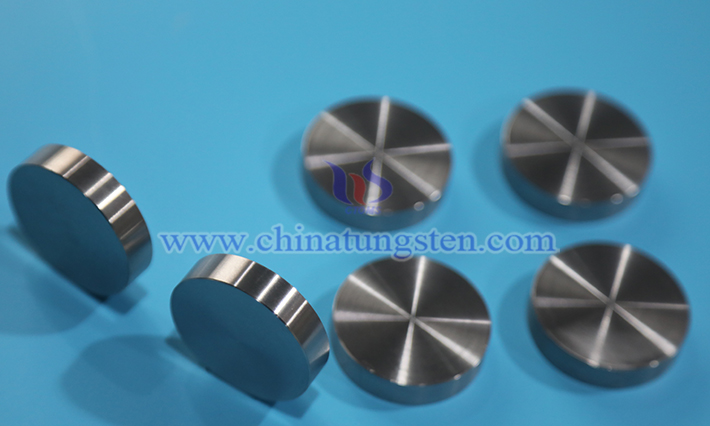

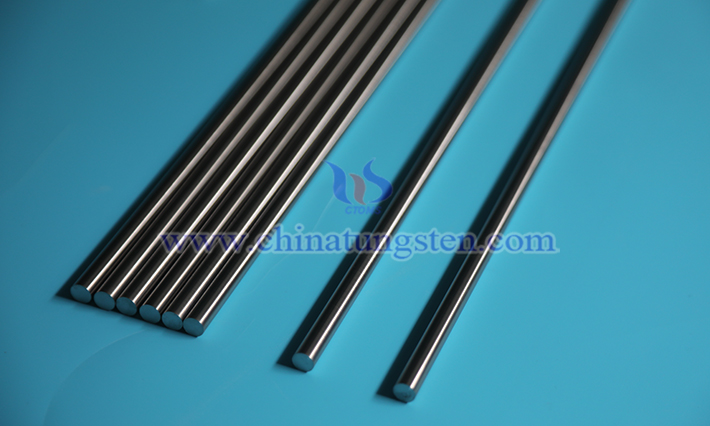

Tungsten-nickel-iron alloy (W-Ni-Fe alloy) is a high-density alloy with tungsten as its matrix, allowing for a balance of density, strength, toughness, and cost through the adjustment of the nickel-iron ratio or the addition of trace elements. It is widely used in aerospace, defense, medical devices, and other fields. The alloy’s material composition includes tungsten, nickel, iron, carbon, and other elements.

Influence of Nickel-Iron Ratio on Tungsten-Nickel-Iron Alloy Performance

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 11:27

- Hits: 162

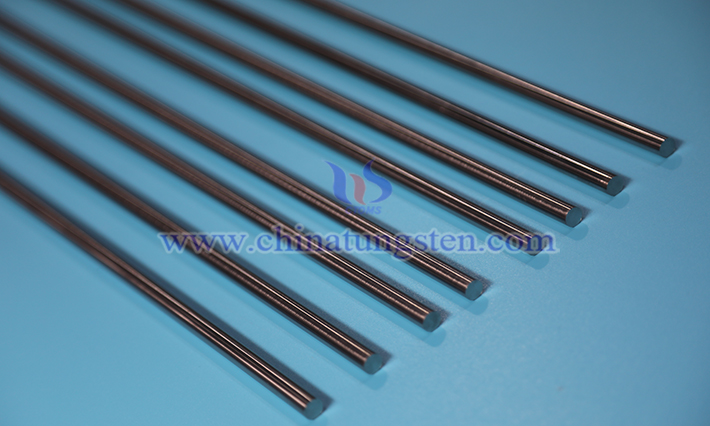

Tungsten-nickel-iron alloy boasts high density, high tensile strength, excellent radiation absorption, and good processability, making it widely applicable in aerospace counterweights, armor-piercing projectile cores, nuclear radiation shielding, and medical equipment protection. Beyond tungsten content, powder characteristics, production processes, and process parameters, the nickel-iron ratio is another key factor influencing its performance.

Influence of Tungsten Content on Tungsten-Nickel-Iron Alloy Performance

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 11:14

- Hits: 157

Tungsten is the core component of tungsten-nickel-iron alloy, imparting exceptional counterweight performance through its high density of 19.35 g/cm³. It also enhances the alloy’s strength and hardness via solid-solution strengthening and particle dispersion strengthening, while optimizing its radiation absorption capacity, making it an ideal choice for high-performance shielding materials.

Factors Influencing the Performance of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 11:06

- Hits: 153

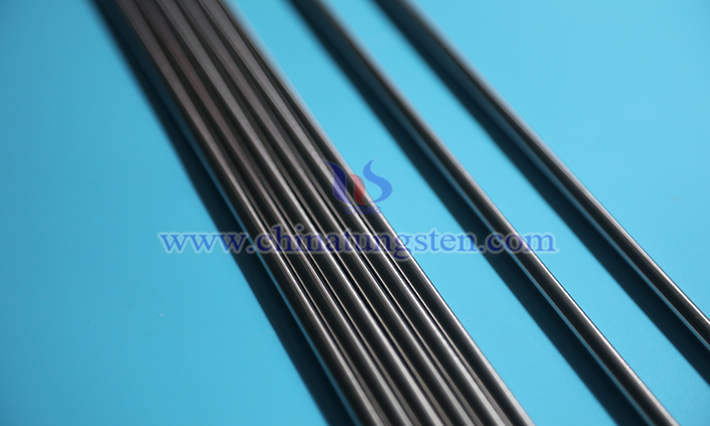

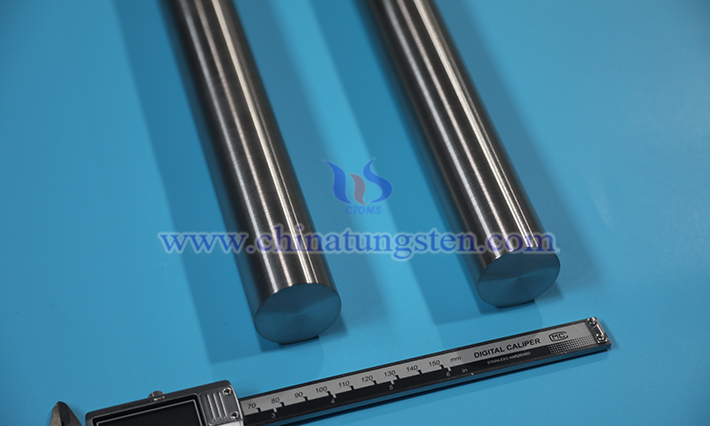

Tungsten-nickel-iron alloy is a material with tungsten as its base, incorporating nickel and iron, where tungsten content typically ranges from 90% to 98%, and the nickel-to-iron ratio is commonly 7:3 or 1:1. It exhibits high density, high strength, and excellent radiation shielding capabilities, finding wide use in counterweights and shielding applications. However, its performance is not fixed and is influenced by factors such as composition ratio, raw material quality, forming process, and heat treatment parameters.

Properties of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Monday, 07 July 2025 10:58

- Hits: 161

In the expansive realm of materials science, tungsten-nickel-iron alloy garners significant attention for its unique properties and broad applications. As the name suggests, it is an alloy based on tungsten, with nickel and iron added, typically in a nickel-to-iron ratio of 7:3 or 1:1, and tungsten content ranging from 90% to 98%. This composition endows it with a host of exceptional characteristics.

sales@chinatungsten.com

sales@chinatungsten.com