Tungsten Crucible Production Mode-From Welding to Sintering

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 19:01

- Written by Yahong

- Hits: 358

Tungsten crucible, as an important component of rare earth smelting, its performance and using life is very important. Previously, the main method of making tungsten crucible to melting rare earth is through molybdenum, tungsten, and tantalum rolled and welded to the slab. However, this crucible welds exist hortcomings; it would seriously affect its using life. Especially when it is at high temperatures, if use such a crucible to smelting high purity rare earth metal, its lifetime will be short, and this phenomenon will be very prominent. Therefore, the overall state of sintering tungsten crucible emerged, this kind of crucible, compared with other types of crucibles, it is with high purity, high density, easy to use, long life, for little smelting metal pollution and other properties. And it is widely used in the rare earth industry, which is tungsten processing products development and application of important results.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy in Nuclear Medicine

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 19:01

- Written by wenjing

- Hits: 403

Tungsten alloy has excellent radiation attenuation properties, allowing the thickness of shields to be reduced, while still effectively blocking harmful X-ray and gamma radiation.

Radiation is an effective tool within nuclear medicine for both diagnostics and treatment of patients. Techniques such as SPECT and PET utilize radioactive materials injected into the patient, which are then monitored by gamma cameras (SPECT) or scanners (PET) to detect the presence of tumours in the body.

The benefits of tungsten alloy in nuclear medicine:

High radiation attenuation; good shielding capability

Thinner and often lighter than equivalent lead shields

Easy to sterilise and keep clean

Non-toxic

Easily machined with conventional tools

Hard and durable – no need for coating

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 18:59

- Written by Yahong

- Hits: 404

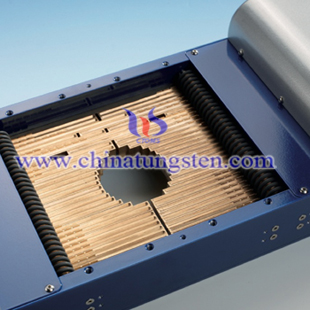

Tungsten crucible is one of deep processing of tungsten products, so it owns the properties of tungsten (high melting point, high boiling point, wear resistance, corrosion resistance, good thermal conductivity, good conductivity, good harden ability, low expansion characteristics at high temperatures, etc.).

Its molding type can be divided into the following types: sintering molding, welding molding, pressing molding, spinning molding. Or turning molding by using tungsten rod (generally its relatively size is small), etc., or the use of pure tungsten plate, tungsten sheet and pure tungsten rod processing through the appropriate process form. Tungsten crucible is used in the conditions that it is in vacuum, in inert gas, and the temperature is below 2600℃. Tungsten crucible is widely applied in quartz glass, rare earth smelting, electronics coating, crystal growth and other industries.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Bits

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 17:52

- Written by Cristina

- Hits: 420

Tungsten carbide button bit is also called cemented carbide button bit. It has many advantages like good wearing resistance, high abrasion resistance, high corrosion resistance, high tenacity, high temperature resistance, high hardness and high density. Tungsten carbide button bits have a thin metal blade or disk with a sharp, usually toothed edge. Tungsten carbide button bits are used for cutting wood, metal, or other hard materials. They can be hand-operated or power-driven. Tungsten carbide button bits are used in surface processing of cast irons, nonferrous metal and alloys, as well as nonmetal materials for hard metal, carbide rough turn, rough planning, and precision milling.

Tungsten carbide road digging button bits are used to mining the road. It can be used to reduce wear on rubbing surfaces found in roller cone drill bits, diamond bits, down-hole stabilizers, and numerous other applications.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rock Drill Button Surface Damage

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 17:51

- Written by Cristina

- Hits: 415

Wear phenomena on tungsten carbide buttons tested in percussive drilling of Kiruna-magnetite under realistic conditions have been studied with scanning electron microscopy, light optical microscopy and energy dispersive X-ray spectroscopy. In addition, a comprehensive literature study has been performed. The aim has been to chart wear phenomena, such as crack formation, occurrence of reptile skin and various wear mechanisms.

It is shown that surface cracks form shortly after drilling has started. Also the valleys and plateaus characterizing the reptile skin pattern were found after only short drilling periods. It appears that the formation of the initial surface cracks and the reptile skin pattern are separate mechanisms, which presumably interact. In addition to the formation of cracks, there is also a continuous wear of the buttons. This is assumed to be caused by wear fracturing and pullout of tungsten carbide (WC) grains or wearing of cobalt (Co) by abrasion.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button with Increased Wear Resistance

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 17:49

- Written by Cristina

- Hits: 397

In U.S. Pat. No. 4,743,515, tungsten carbide buttons are disclosed with a core of finely and evenly distributed eta-phase embedded in the normal alpha+beta-phase structure, and a surrounding surface zone of only alpha+beta-phase. (alpha=tungsten carbide, beta=metal binder, e.g., Co, and eta=M6 C, M12 C and other carbides, e.g., Co3 W3 C). In the inner part of the surface zone situated close to the core of that body, the Co-content is higher than the nominal content of Co. The Co-content in the outermost part of the surface zone is lower than the nominal and increases in the direction towards the core up to a maximum usually at the eta-phase core.

Tungsten carbide button for rock drilling comprises a core and a surface zone surrounding the core whereby both the surface zone and the core contains WC (alpha-phase) and a binder phase based on at least one of Co, Ni, or Fe and the core in addition contains eta-phase. The eta-phase core extends to the very top (working) surface of the button and as a result is obtained longer life and higher drilling rate particularly for rotating crushing drilling, cutting drilling and percussive drilling in soft rocks.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Wedge Button

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 17:48

- Written by Cristina

- Hits: 370

Tungsten carbide wedge button used primarily as a medium and small-scale tooth carbide buttons for inlay system cone drill and impact drill, drilling in soft and hard rock, but also can be used for other drilling alloy sheet. It has superior wear resistance and toughness, compared with similar products has higher drilling speed.

A variety of models and sizes of tungsten carbide wedge buttons:

|

Type |

D |

H |

h |

θ1 |

θ2 |

SR |

e |

α |

|

CT0809 |

8.25 |

9.0 |

5.5 |

22.5 |

45 |

1.35 |

1.0 |

20 |

|

CT1013 |

10.25 |

13.0 |

9.0 |

22.5 |

45 |

2.50 |

1.6 |

18 |

|

CT1115 |

11.25 |

15.0 |

8.0 |

22.5 |

30 |

2.75 |

1.5 |

18 |

|

CT1114 |

11.30 |

14.0 |

8.1 |

21.5 |

37.5 |

3.50 |

1.3 |

20 |

|

CT1117 |

11.30 |

17.1 |

9.1 |

20 |

26.5 |

3.00 |

1.3 |

20 |

|

CT1118 |

11.30 |

17.8 |

10.1 |

17.5 |

25 |

3.15 |

1.1 |

18 |

|

CT1621 |

16.35 |

21.0 |

11.0 |

22.5 |

35 |

2.60 |

2.0 |

18 |

|

CT1623 |

16.35 |

23.0 |

12.0 |

18 |

30 |

3.00 |

2.0 |

18 |

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Types

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 17:46

- Written by Cristina

- Hits: 422

According to different shapes, tungsten carbide button can be devided into conical button, wedge button, spoon button, and claws button .Different tungsten carbide buttons have different usage.

1.Tungsten carbide conical button. Tungsten carbide conical button is a button which drill point is round. It can be used for manufacturing compacts of roller cone bits with high buttons exposure.

2.Tungsten carbide wedge button. Tungsten carbide wedge button used primarily as a medium and small-scale tooth carbide buttons for inlay system cone drill and impact drill, drilling in soft and hard rock, but also can be used for other drilling alloy sheet.

3.Tungsten carbide spoon button. Tungsten carbide spoon button inserts made for roller cone bit, the way to cutting the broken rock, suitable for high speed drilling of soft rock.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tipped Annular Cutter (2)

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 14:10

- Written by lucy

- Hits: 393

Tungsten carbide tipped annular cutter is a suitable solution for a wide range of possible applications, it is combined extreme hardness and durability, and its material is harder than the most of material to be drilled.

There are various available sizes of tungsten carbide tipped annular cutters for different applications, generally the diameter varies from 12 mm to 200 mm and larger if required, and among the manufacturers the sizes are differed as well. For the length of the annular cutter, it largely depends on the thickness of the material to be drilled. The most popular cutter length in the market , including 30 mm, 55 mm, 75 and 110 mm. Annular cutters are also called as core drills because, after drilling hole, the drilled material is ejected from the cutter in the form of a cylindrical blank, this blank is called a core.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tipped Core Drill

- Details

- Category: Tungsten Information

- Published on Monday, 08 June 2015 14:09

- Written by lucy

- Hits: 440

Tungsten carbide tipped core drill is made from tungsten carbide material on its tip. It is known that tungsten carbide is a extreme hard manmade material, since the material price is high, the tungsten carbide tipped core drill is more expensive then HSS core drill, but it has better performance in terms of drilling faster and easier to make bigger holes. Generally, tungsten carbide tipped core drills are cheaper for bigger diameter.

There are different types in tungsten carbide tipped core drills, which are all efficient for cutting hard material. Compared to HSS core drills, the main disadvantage of tungsten carbide tipped core drill is the chances of tip breakage is more . Another shortcoming related to maintenance is the tungsten carbide tipped core drill is not able to reground. Once the its core drill is damaged it has to be thrown away, it can not be reused like the HSS core drills. It is always recommended by manufacturers to use core drills only for larger diameter and for very hard material, while giving priority to HSS core drills because of its price and re-sharpening advantages.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com