Tungsten Carbide Rod Inspection Standards

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 17:57

- Written by Cristina

- Hits: 453

Tungsten Carbide Rod Inspection Standards

Tungsten carbide rod is in huge demand for its very high strength as well as rigidity. Its comprehensive strength is higher than all existing melted and cast or forged metals and alloys. Its compositions range from two to three times as rigid as steel and four to six times as rigid as cast iron and brass. Tungsten carbide rods maintain all the features of tungsten carbide with availability of different grades.

Manufacturers follow the established standards for all tungsten carbide grades and control checks are performed at each operation. They also check the grain sizes and do chemical analysis to assure that all products conform to the set standards, Test are made to determine physical properties of the products for their hardness, strength and density. They also observe for any fractured and polished surfaces through micrographic test with the test results being recorded before shipping the product to the final customers or users. Some manufactured do provide certification of test results when asked by the customers.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Special Forms Tungsten Oxide Producing Methods

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 17:56

- Written by xiaoshan

- Hits: 396

Nano tungsten oxide has strong organizational ability to grow and in a stable reaction conditions the interactions between molecular are fairly obvious. Molecular can epitaxial growth which is accordance with lattice arrangement strictly and to form the formation ratio complete and single component structure. With the improvement of nano technology, now there have been some special form of tungsten oxide, including arborescent, clitheriform, nanorods, nanowires and other special forms. There are many methods to produce special form nano tungsten oxide which can be divided into three types: high-temperature synthesis, hydrothermal synthesis method, and solution low temperature synthesis method. Although high-temperature synthesis method is most common, but it has high requirements in equipment so this method is difficult wildly be used. The hydrothermal synthesis method is acidification W (CO) 6 and ammonium tungstate, the reaction is from 2 to 100 hours at 160-200 ℃ range in autoclave for produce different shapes of nanorods. This method is low cost so it can be widely used than high-temperature synthesis method. Solution low temperature synthesis method is a new invention so in produce special morphology tungsten oxide is not mature, but the method has attracted much attention and the prospects are very broad.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Surface Roughness Affecting Factors

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 17:55

- Written by Cristina

- Hits: 459

Tungsten Carbide Rod Surface Roughness Affecting Factors

Tungsten carbide rod surface roughness affecting factors including the granularity of grinding wheel, rotating speed of grinding wheel, the concentration of grinding fluid and granularity of tungsten carbide rod.

1.The granularity of grinding wheel. The grinding process of tungsten carbide rod is generally divided into two to three steps. The first few steps are coarse grinding and the last step is fine grinding. The higher the granularity of grinding wheel is, the finer the diamond particle will be. The grain will be more detailed and the product will be brighter.

2.Rotating speed of grinding wheel. If the rotating speed is high, the friction period with tungsten carbide rod will be shorter, so there will be less grain formed on the surface of tungsten carbide rod.

3.The concentration of grinding fluid. Although grinding fluid is just an auxiliary material, the concentration will also affect the surface roughness of tungsten carbide rod.

4.Granularity of tungsten carbide rod. Tungsten carbide rod is made of many particles. The finer the particle is, the gap between particles will be smaller, thus the density will be better. It is easier to polish.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Trioxide Photochromic Properties

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 17:54

- Written by xiaoshan

- Hits: 420

Tungsten trioxide as a transition metal oxide is an excellent photochromic material. The study found it under ultraviolet light will turn blue. And it can use in optical information storage and optical recording and other filed. Photochromic refer to compound A is subjected to the wavelength λ1 of light, can be generated product B specific chemical reaction which is different structures and spectroscopic properties. And on the other hand in the light of the wavelength λ2 or heating, products B can reversible generation compound A. The basic features of this process are: A, B under certain conditions is stable and color disparity is significant different. What’s more in the process A, B is reversible. When the energy of light which is greater than the band gap of WO3 light on the sample, then the electron-hole pairs are generated. Photo-generated electrons into the conduction band of WO3, and adjacent W6 + combine to generate W5 +. At the same time electron holes can react with water molecule which is adsorbed on the sample surface, weakening the water molecules bond H-O, caused by the decomposition of water molecules, generating protons. Proton release into the WO3 then is become blue H2WO3 which is tungsten bronze.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantages of Tungsten Alloy Industrial Radiography Shielding

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 16:57

- Written by wenjing

- Hits: 458

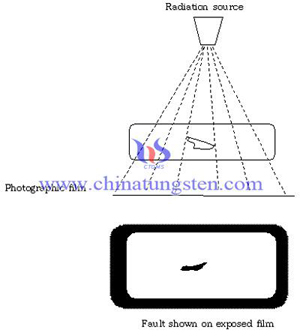

Industrial radiography is a method of inspecting materials for hidden flaws by using the ability of short X-rays and gamma rays to penetrate various materials. Tungsten alloy shield is widely used to produce radiography welding inspection shielding, ionizing radiation detector shielding, and container inspection radiation shielding in industrial radiography.

The advantages of tungsten alloy industrial radiography shielding:

Tungsten alloy materials has high density,and the characteristics of environment protection. Due to tungsten alloys have the ability of various high-ray shielding,tungsten alloy can be the good materials for industrial radiography shielding. The thickness 3mm of tungsten alloy can shield 95% of 150keV γ radiation. Tungsten alloy materials are suiting for high spatial resolution occasion, such as welding inspection.Tungsten alloy industrial radiography shielding with higher spatial resolution than lead shielding.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Radiation Shielding in Nondestructive Testing

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 16:53

- Written by wenjing

- Hits: 398

Nondestructive testing or Non-destructive testing (NDT) is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage.

Industrial radiography uses gamma radiation to detect structural faults in materials such as metal and concrete. As with pipeline inspection, the equipment uses tungsten alloy radiation shielding for non-destructive testing, which is coupled with tungsten collimator. Gauging radioactive sources are used in industrial processes to measure thickness, density or levels of materials during production e.g. paper, plastic film, steel sheet or surface coatings.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Abrasive Particle Size Selection

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 16:21

- Written by limei

- Hits: 409

Tungsten carbide cutting tools abrasive particle size selection is mainly on account of the surface roughness of tungsten carbide cutting tools and grinding efficiency requirements for salvation, and also consider the poor thermal conductivity of tungsten carbide cutting tools, grinding prone to crack this important factor, which generally according to the following principles:

The contact area between the grinding wheel and tungsten carbide cutting tools is large, ungsten carbide cutting tools abrasive particle size selection should follow the choice of some of the coarser grinding wheel, for example, the same surface grinding, grinding wheel with a cross-section than the periphery of the grinding wheel coarse granularity to some, when the contact area is small, the wheel can be used some fine-grained, wet than dry grinding with the wheel. You can finer granularity. This choice is easy to make, mainly from the grinding heat generated carbide grinding cracks factor to consider.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools PVD Coating Technology

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 16:19

- Written by limei

- Hits: 437

Tungsten carbide cutting tools PVD coating technology can improve the overall performance of tungsten carbide cutting tools. Due to low deposition temperature on the sharp edges can be coated with a smooth, fine-grained, crack-free coatings and excellent residual stress, etc., tungsten carbide cutting tools PVD coating technology has been in the field of tungsten carbide cutting tools and other wide range of applications.

Development of tungsten carbide cutting tools PVD coating technology has led to the emergence of the commercialization of new compounds such as compounds TiCN, TiALN and TiZrN and CrN like. In the cutter, drill, threading, grooving and cutting, such as processing, the application of tungsten carbide cutting tools PVD coating technology is widely than CVD coating technology .In the processing of high temperature alloy, tungsten carbide cutting tools pvd coating technology can achieve very good results.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Diamond Coated Tungsten Carbide Cutting Tools

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 16:17

- Written by limei

- Hits: 476

Diamond coated tungsten carbide cutting tools is one of coated tungsten carbide cutting tools which has incomparable superiority. Diamond coated tungsten carbide cutting tools has high hardness, low coefficient of friction, high thermal conductivity and low coefficient of thermal expansion. However, the diamond will work with the Periodic Table Group IVA to Group VIIA elements react, so diamond coated tungsten carbide cutting tools can only be used in machining the workpiece scrap metal and non-metallic materials.

Diamond coated tungsten carbide cutting tools has a small planar structure, which makes its surface rough. In the back of the tool, this facet will cause deterioration of the workpiece surface finish.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Router Bit Flutes

- Details

- Category: Tungsten Information

- Published on Thursday, 04 June 2015 15:21

- Written by lucy

- Hits: 440

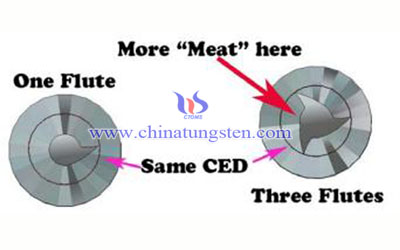

The flutes of the tungsten carbide router bit refers to the deep helical grooves running up the bit. The quantity of the flutes is the number of the cutting edges that are made in the body of the bit. Since the cutting purposes and materials to be cut are varied, the flute is one of the geometry of the bit could make an effort in matching those specific cutting purposes.

Generally, the tungsten carbide router bits are available for one, two and three flutes (less commonly) , and more flutes increases the strength of the tool, but reduces space for chip flow. For example, one flute bit has more room for chips being evacuated, making faster cutting possible, while three flute bit is stronger and cuts with a finer finish.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com