Tungsten Crucible – Sintering Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 18:41

- Written by Yahong

- Hits: 384

Sintering tungsten crucible uses a crucible-shaped mold to press out of the crucible, and then by sintering. After sintering it, by polishing it, to ensure its smooth surface finishment, and has a metallic luster. Surface finishment can be controlled at Ra1.6um.

Sintering tungsten crucibles’ tungsten purity is above 99.95%, and a density of 18.2g / cm3. Sintering tungsten crucible height can reach to 850mm, maximum diameter can be 500mm, the wall thickness is between 8 ~ 12mm. Sintering tungsten crucible diameter and height tolerance can be controlled within +/- 0.5mm. Sintering tungsten crucible is mainly used for Sapphire furnace, to produce wafers.

Tungsten crucible performance:

Tungsten crucible performance mainly has the following points, wear resistance, high melting point, high boiling point, corrosion resistance, high temperature resistance, high thermal conductivity; good harden ability, low expansion characteristics at high temperatures.

Tungsten crucible purposes:

Tungsten crucible is widely used in crystal growth, rare earth smelting, electronics coating, quartz glass and other industries.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Crucible - The Use of Crucible in lab

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 18:38

- Written by Yahong

- Hits: 449

Tungsten crucible is a vessel or melting pot, whose shape is similar to the pot or cup, which is also a kind of crucible and is made of extremely refractory material (such as graphite, quartz, clay, china clay or compare refractory metal, etc.) .

Crucible is a bowl-shaped vessel, which has a ceramic-like deep bottom. The following is something about the use of crucible in lab. Because crucible’s high temperature resistance performance is better than glass crucibles’, so when there is a solid requires heating or melting, we must use it. When using a crucible, in order to prevent heat objects bounces or melting liquid spills, a crucible cover is usually needed to diagonally cover on the crucible, to allow air to have a freely access and for possible oxidation reactions. Because the bottom of the crucible is very small, generally you need to put it on the pipeclay triangle and then directly heat it. Crucible can be positively or obliquely put on the pipeclay triangle, according to the requirements. After heating, the tungsten crucible should not immediately be placed on a cold metal table, to prevent it from being broken due to the rapid cooling.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effective Treatment of Tungsten Multileaf Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 18:29

- Written by wenjing

- Hits: 396

Due to tungsten alloy has excellent radiation attenuation properties, with thinner thickness but high effective in blocking harmful X-ray and gamma radiation, , it is widely used in multileaf collimator. During radiotherapy, tungsten multileaf collimator are delivered while the gantry rotates around the patient. The intensity of the radiation is modulated and the shape of the beam is dynamically adjusted by moving the tungsten alloy leaves. The gantry speed and dose rates may also be changed during the rotation. This provides the potential to create effective treatment that are high standard with a shorter treatment time.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Multiple Layer Multileaf Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 18:27

- Written by wenjing

- Hits: 422

Tungsten multiple layer multileaf collimator for shaping radiation beam. The collimator comprises first and second layers of a plurality of elongated radiation blocking tungsten alloy leaves. The leaves of each layer are arranged adjacent one another so as to form two opposed rows of adjacently positioned tungsten alloy leaves and are movable in a longitudinal direction which is generally traverse to the direction of the beam so as to define a radiation beam shaping field between the opposed ends of tungsten alloy leaves. The layers are arranged one above another in the beam direction and offset in a lateral direction generally transverse to the beam direction and orthogonal to the longitudinal direction so that spaces between adjacent tungsten alloy leaves of the first and second layers are positioned over and under, respectively, tungsten alloy leaves of the second and first layers, respectively.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

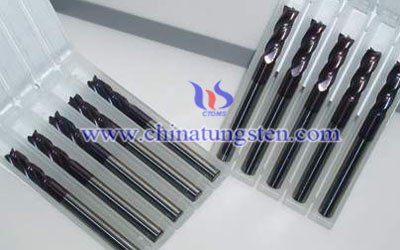

Tungsten Carbide Cutting Tools Chipping Reasons

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 16:36

- Written by limei

- Hits: 441

Master tungsten carbide cutting tools chipping reasons is helpful to take appropriate measures to address chipping problems of tungsten carbide cutting tools, tungsten carbide cutting tools chipping reasons reflect in five aspects.

1. Poor choice of tungsten carbide cutting tools grade, specification.

2. The geometry of the inappropriate choice of tungsten carbide cutting tools (such as front and rear angle is too large, etc.).

3. Incorrect welding process of tungsten carbide cutting tools, resulting in excessive stress welding or welding cracks.

4. Unreasonable selection of tungsten carbide cutting tools. Such as excessive, machine tools boring car; intermittent cutting, high cutting speed; when blank margin uneven, the depth of cut is too small

5.Insufficient coolant flow or incorrect filling method which results in tungsten carbide cutting tools damage.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Grinding Features

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 16:36

- Written by limei

- Hits: 400

Tungsten carbide cutting tools inherited high hardness, brittleness, thermal conductivity and other characteristics of tungsten carbide materials, making tungsten carbide cutting tools grinding have great difficulty. Tungsten carbide cutting tools grinding features can be concluded in two aspects.

First, tungsten carbide cutting tools grinding features reflects in that tungsten carbide cutting tools grinding process requires a better self-grind resistance and good cooling, so as to reduce the production of grinding cracks.

Second, tungsten carbide cutting tools grinding features reflects in that diamond grinding wheels are widely used in tungsten carbide cutting tools grinding due to high grinding efficiency, small grinding force, easy to passivation and lower local temperature grinding surface contact area ( generally at 400 ℃ for around), etc.. But in the diamond grinding wheel process of tungsten carbide cutting tools, due to large grinding allowance, processing methods, diamond tools and grinding systems feature if choose unproperly, will result in instantaneous temperature of tool grinding surface is too high , resulting in grinding cracks.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Chipping Countermeasures

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 16:36

- Written by limei

- Hits: 385

Master effective tungsten carbide cutting tools chipping countermeasures is helpful to prevent chipping problems of tungsten carbide cutting tools, tungsten carbide cutting tools chipping countermeasures mainly in the following areas:

1. Increase the blade thickness of tungsten carbide cutting tools, select grades with high bending strength and high toughness.

2. Use a larger negative blade angle of tungsten carbide cutting tools in order to avoid geometric parameters.

3. Avoid using enclosed on three sides blade slot structure, as mechanical reinforcement structure.

The transition for carbide tool wear should be timely tool change or replace the cutting edge.

4. Increase the flow of cutting fluid, rational layout location of the cutting fluid nozzles, using effective cooling methods such as spray cooling, avoid cutting fluid flow is insufficient or incorrect filling method, resulting in tungsten carbide cutting tools damage.

5 Reduce the overhang of tungsten carbide cutting tools.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

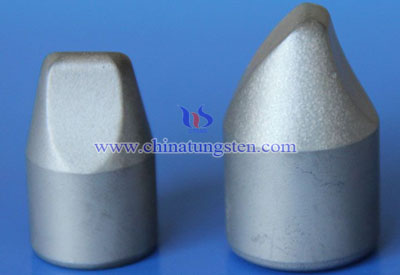

Tungsten Carbide Mushroom Button

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 16:25

- Written by Cristina

- Hits: 387

The shape of tungsten carbide mushroom button is like a mushroom, it is also called cemented carbide mushroom button. Because of its high wear resistance, high bending strength and high hardness, tungsten carbide mushroom button is ideally suited for wear parts, other machine parts and dies which are subject to severe service conditions, such as high temperatures, corrosion and abrasion.

A variety of models and sizes of tungsten carbide mushroom buttons:

|

Type |

Size |

|||||

|

D |

H1 |

H2 |

h |

R |

A |

|

|

CT1822 |

18 |

10 |

22 |

8.0 |

30 |

1.5 |

|

CT2025 |

20 |

12 |

25 |

10.0 |

35 |

1.5 |

|

CT2027 |

20 |

12 |

27 |

10.5 |

35 |

4.0 |

|

CT2128 |

22 |

14 |

28 |

12.0 |

40 |

1.5 |

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Spoon Button

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 16:22

- Written by Cristina

- Hits: 383

Tungsten carbide spoon button is the shape like spoon. It is also called cemented carbide spoon button. It has many advantages like good wearing resistance, high abrasion resistance, high corrosion resistance, high tenacity, high temperature resistance, high hardness and high density. Tungsten carbide spoon button made for roller cone bit, the way to cutting the broken rock, suitable for high speed drilling of soft rock.

A variety of models and sizes of tungsten carbide spoon buttons

|

Type |

Size |

||||||||

|

D |

H |

h |

e |

α |

SRa |

SRb |

SRc |

θ |

|

|

CT1621 |

16.35 |

21.0 |

9.9 |

2.0 |

18 |

15.0 |

23.0 |

2.5 |

30 |

|

CT1623 |

16.35 |

23.0 |

11.9 |

2.0 |

18 |

15.0 |

23.0 |

2.5 |

30 |

|

CT1624 |

16.35 |

24.2 |

12.8 |

1.2 |

18 |

15.0 |

24.0 |

2.3 |

30 |

|

CT1930 |

16.35 |

30.0 |

17.0 |

2.0 |

18 |

16.0 |

25.0 |

3.0 |

30 |

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button in rock drilling

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 June 2015 16:18

- Written by Cristina

- Hits: 379

There are three main groups of rock drilling methods: percussive, rotary crushing and cutting rock drilling. In percussive and rotary crushing rock drilling the bit buttons are working as rock crushing tools as opposed to cutting rock drilling, where the tungsten carbide button work rather as cutting elements. A rock drill bit generally consists of a body of steel which is provided with a number of inserts comprising tungsten carbide. Many different types of such rock bits exist having different shapes of the body of steel and of tungsten carbide button as well as different numbers and grades of the inserts.

For percussive and rotary crushing rock drilling, tungsten carbide button inserts often have a rounded shape, generally of a cylinder with a rounded top surface, generally referred to as a button.

For cutting rock drilling, tungsten carbide button inserts often are provided with an edge acting as a cutter.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com