Tungsten Carbide Button Cobalt Content

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:58

- Written by Cristina

- Hits: 382

As the cobalt content increases, tungsten carbide hardness and wear resistance decrease, bending resistance increase, but the compressive strength is weaker than before. Also coefficient of thermal expansion rises, thermal conductivity falls down; elasticity modulus and rigidity modulus descend. Bearing fatigue point goes up.

When tungsten carbide button cracks, cobalt phase caused plastic deformation. Carbide stays almost the same, its yield strength is quite high, so it has a certain limitation for plastic deformation of cobalt phase. Low cobalt content tungsten carbide fracture toughness is KIC=3+90λ½, high cobalt content tungsten carbide fracture toughness is KIC=57+12λ½. Tungsten carbide fracture toughness ascents along with the increase of cobalt content. The maximum cobalt content is 29 percent. Tungsten carbide bending strength also goes up with cobalt content. But when cobalt content reaches 10 percent or more, bending strength goes down.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxides Particle Morphology and Size

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:57

- Written by xiaoshan

- Hits: 386

Through color electron microscopy observing the shape and size of the tungsten oxides found different phase component tungsten oxides have different particle morphology and size. Violet tungsten oxide (VTO) particles are rod-shaped, and the rest of the tungsten oxides particles morphology is nearly spherical. VTO particle size are large than other tungsten particle size. The blue tungsten oxide (BTO) which the main phase is ATB has minimum particle when compare to other tungsten oxides. Using electron diffraction pattern found violet tungsten oxide is single crystal particles, while the other was a polycrystalline particle. Where rod-shaped VTO length has several microns and cross-sectional dimensions is about 100 ~ 200nm. In the primary phase of ATB BTO particle cross-sectional dimensions is about 10nm. WO20O58 main phase of BTO particle cross-sectional dimensions is about 40nm which is similar to WO3 particle cross-sectional dimensions. From the degree of aggregation between the particles, the smallest gap between the particles is ATB. The microscopic particle size of the tungsten oxide and its macroscopic FSSS size compared to, we can see that the two are not related links.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Grain Size

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:56

- Written by Cristina

- Hits: 376

According to different applications, tungsten carbide button producing requires middle or macro tungsten carbide grain size.

Tungsten carbide grain size affects tungsten carbide button properties from the following aspects:

1.Wear resistance and hardness. Tungsten carbide button hardness is related to cobalt content and tungsten carbide grain size. With the increase of cobalt content and tungsten carbide grain size, tungsten carbide button wear resistance and hardness decrease. The finer the tungsten carbide grain size, the better the wear resistance.

2.Bending strength. If the tungsten carbide grain size is 2um, bending strength arises with cobalt content. If tungsten carbide grain size is between 3um-5um, bending strength arises at the beginning along with cobalt content.

3,Fracture toughness. For the tungsten carbide button with the same cobalt content, if the tungsten carbide grain size is larger, then the fracture toughness is higher. On the contrary the smaller the tungsten grain size is, the lower the fracture toughness will be.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Observing Tungsten Oxides Aggregate

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:55

- Written by xiaoshan

- Hits: 376

Using scanning electron observed tungsten oxides aggregate exterior morphology and the internal structure found little difference in different tungsten oxides, which have retained the appearance characteristics of raw material APT. But the particle size change largely. Different tungsten oxides surface features are not quite the same which observed by high-powered electron microscope. Including yellow tungsten oxide and blue tungsten oxide which the W20O58 and ATB are main phase large particles have varying degrees fragmentation and full of cracks. The morphology of violet tungsten is different with other three tungsten oxide. Its particles are loose and large which is made up of needle-like or rod-like grains.

Observe the internal structure of tungsten oxide aggregate found all the internal structure of tungsten oxides have a wealth of cracks, on the other hand violet tungsten oxide not only has rich crack and the interior particles are needle or rod shape. This structure making violet tungsten oxide has large particle voids, making its particles more loosely, so it is conducive to the hydrogen get into particle inside and steam escape in reduction process. So that the reduction reaction may take place not only at the surface, can occur simultaneously in the interior, beside the reaction speed is quick and tungsten powder are fine and uniform.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Carbon Content

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:55

- Written by Cristina

- Hits: 365

Tungsten carbide carbon content is an important factor that will affect tungsten carbide properties.

1.Bending strength. Normally, bending strength reaches largest where the carbon content is high for the low cobalt content tungsten carbide YG10. For the high cobalt content tungsten carbide YG20, bending strength reaches largest where the carbon content is low. Carbon content too much or less will affects the bending strength of tungsten carbide button.

2.Hardness. The change of carbon content will result in the fluctuation of tungsten carbide phase and cobalt phase. When the carbon content is insufficient, binder phase decreases thus the hardness falls down.

3.Density. If the carbon content decrease, then the density increases. If carbon content increases, tungsten carbide button density decreases.

4.Corrosive resistance. A bit carbon content combines cobalt content will increase the corrosive resistance of tungsten carbide button. On the contrary, exceeded carbon content will lower the corrosive resistance of tungsten carbide button.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Producing

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:53

- Written by xiaoshan

- Hits: 373

Tungsten oxide is an important raw material for producing carbide. With the carbide industry development the quality and performance of the products have become more sophisticated. So to understand the performance of tungsten oxide for producing carbide with high performance has a significant advantage. Almost all tungsten oxides are based on APT (ammonium noon) as raw materials and calcined to produce. With different calcine conditions, the tungsten oxide powder is different. For example, using the same batch APT as raw material through different calcination process will produce violet tungsten oxide, blue tungsten oxide and yellow tungsten oxide. Each one has its own unique crystal structure, so they are not quite the same physical properties.

Violet tungsten oxide phase component is WO2.72 for its unique crystal structures so much use for producing fine tungsten oxide powder and fine tungsten carbide powder. Blue tungsten oxide phase component in theory is WO2.97. But in the actual blue tungsten oxide is typically a mixture of many tungsten oxides, including yellow or violet tungsten oxide phase. Yellow tungsten oxide has various crystal forms with different calcination temperature will obtain different WO3 crystal form. At a calcination temperature of 700 ℃ may producing orthorhombic tungsten trioxide.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Quality Control Methods

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:53

- Written by Cristina

- Hits: 406

Tungsten carbide button quality control can be devided into inner quality control and external quality control. Inner quality control includes ingredient and construction. External quality control includes size and surface roughness.

1.Tungsten carbide button size, bending, burr, deformation should be within the standard.

2.Tungsten carbide button should be made under high temperature and long term carbonization. Carbon content should be between 6.14-6.20%. Tungsten carbide grain size is ought to be 2-3um.

3.Tungsten carbide carbon content should be within a certain limit. Magnetic saturation value of tungsten carbide button should be 93%-96%.

4.According to usage of tungsten carbide button, cobalt content should be 6%-16%. Wet grinding period should be within 24 hours. Sintering temperature should be high enough to increase tenacity of tungsten carbide button.

5.Reduce voids and large grain size inside of tungsten carbide button.

6.Use low pressure sintering, make the voids of tungsten carbide button smaller, enhance fracture toughness.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool’s Tool Wear in Particle Board Machining (1)

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:32

- Written by lucy

- Hits: 424

It is known that, during the particle board cutting processes, as they can have abrasive fragments, loose micro-fragments can penetrate the tool under cutting pressure and preferentially remove the cobalt, which would affect tool wear.

When applying tungsten carbide cutting tool in particle board machining, a maximum wear tool area presents, which corresponded to the region in contact with the board surface whereas a wear minimum near the center of the cutting region. This profile is attributed to differences in board density and silicate content. It could be suggested that particleboard which can exhibit low tool wear in both the surface and middle layers can be manufactured depending on its structure and the composition of the materials used.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool’s Tool Wear in Particle Board Machining (2)

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:29

- Written by lucy

- Hits: 388

In terms of observing the tungsten carbide cutting tools’ cutting edges when machining three layered southern pine particleboard, the blunting was attributed to a combination of the effects of cured urea-formaldehyde resin and the higher board density. A similar effect of the resin glue content on wear was also shown in recently research, with the increasing of board density, silicates and resin content, a linear increasing relationship occurs in the abrasiveness of the board. In addition, if the resin content increases from 5 to 8%, there’s no effect on the tool wear while increasing the resin content from 9-11%, the abrasiveness almost doubled.

Most of the wear is found on the clearance face of tool, due to the rubbing action between the tool face and the wood. Less wear is found on the rake face, since no continuous chip is formed in machining synthetic wood products like particle board as they machine mostly by fracture.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Woodcutting Tool Cutting Forces (2)

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:29

- Written by lucy

- Hits: 362

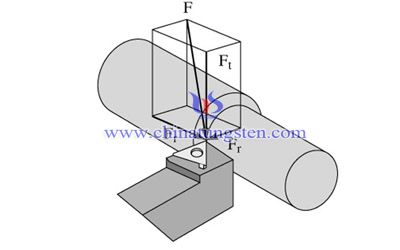

For the tungsten carbide woodcutting tool, the inclination of knife in its holder has an impact on the magnitude of the cutting forces applied as well.

The inclining the knife to the work piece advanced in input energy quantity control, which results in a lower transfer of stress from tool face to wood, hence causing smaller deformation zones in the contact zone. Some researchers measured the normal cutting force for a range of cemented carbides when cutting particleboard and found that the edge recession increased with increasing cutting force for the range of materials tested. The cutting forces measured were dependent on the binder content of the hard metal, with higher forces being recorded with increasing binder content.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com