Cause of Tungsten Tube Surface Longitudinal Cracks

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:38

- Written by Yahong

- Hits: 438

The main cause of CVD tungsten tube longitudinal cracks lies that: the deposition way of the inner wall of tungsten tube and the deposition process is not well controlled. The fundamental reason is that the tensile stress due to tungsten tube’s wall contraction (its cooling speed is too fast, and the amount of reaction gas is too much in unit time). Because the stress is concentrated at the growing crystal grain boundaries, so these positions are easy to crack. Growth of columnar crystals of tungsten tube is growing along the radial direction, leading to rapid expansion of the crack into the grain boundaries.

The depositing of tungsten tube inner wall is by heating the outer wall of the deposited matrix to the deposition temperature.

In the cooling process of the deposition, the inner wall of deposition tungsten tube will cooling rapidly due to continuous passing-through of hydrogen, while the outer wall of the cooling rate will be relatively slow.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Properties

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:38

- Written by Cristina

- Hits: 419

Ammonium metatungstate is also called AMT, it is inorganic chemical product. Its molecular formula is H8N2O4W and molecular weight is 283.9145. CAS number is 11120-25-5;14311-52-5. It is white or slightly yellow crystals which has no harmful components and slightly acidic. The solubility in water is 303.99/loogH:O when 20℃, aqueous fairly stable. It is insoluble in alcohol.

Ammonium metatungstate can be used as catalysts, capacitors, nuclear shielding, flame retardants, corrosion inhibitors raw materials, but also excellent raw materials in the preparation of ultra fine tungsten powder, tungsten heavy alloy powder, phosphotungstic acid, arsenic acid, silicon tungstate. It can also be used as reagents for chemical analysis such as for chemical diagnosis; source material for the preparation of high purity tungsten trioxide used as a thin film substrate for certain semiconductor devices; high purity source material for research in tungsten chemistry; source material for DENOX catalysts industry; as a precursor to a variety of POM (polyoxometalates).

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Blue Tungsten Oxide’s Oxygen Index and Colors

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:36

- Written by xiaoshan

- Hits: 416

Oxygen index have certain impact on the performance and morphology of blue tungsten oxide, researcher determination of oxygen index of blue tungsten oxide by weight method. After experimental data analysis found that the baking temperature has great impact on oxygen content and the color of blue tungsten oxide. When baking temperature at 350 ~ 500 ℃, the oxygen index between 2.96-2.90. Changing the baking temperature, the color and oxygen content of blue tungsten oxide also will change and surface gloss index has varying degrees of change.

At 350 ℃, blue tungsten oxide’s color is yellow-blue and has high oxygen index, matte. As the temperature increases, blue tungsten oxide gradually be reduced, when the baking temperature reaches at 450 ℃blue tungsten oxide’s color translated into blue-black and surface of it has metal light, oxygen index of 2.94. When baking temperature reached 500 ℃, oxygen index of 2.90, blue tungsten oxide color is blue-black. As the temperature continues to rise in parts of blue tungsten oxide restore into WO2.72 , then the blue color of blue tungsten oxide become more deepen and oxygen index further reducing. When baking temperature reaches 550 ℃, it began to appear purple WO2.72, but most retain the blue color which to form a heterogeneous mixture.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Influence Factors of Producing Blue Tungsten Oxide (2)

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:35

- Written by xiaoshan

- Hits: 440

After studies showed a major factors influence blue tungsten oxide (BTO) performance was particle size and production process. The process production conditions including baking temperature, hydrogen flow and baking time. On one hand, under the certain baking temperature, the particle will grow up and the crack will more rough when hydrogen flow decease. But on the other hand when hydrogen flow increase, the particle will finer and uniform. This is mainly because of increased pressure and permeation of hydrogen will change the internal stress of particle, such stress can lead to lattice distortion, resulting in cracking particles. Therefore, the particles tend to rupture and produce a fine particle powder. Baking time also is an important factor for producing fine blue tungsten oxide. The long baking time, the bigger particle and surface crack of blue tungsten oxide. The experiments show, baking solution temperature at 400 ~ 500 ℃, baking time for 30 to 40 minutes, the hydrogen flow 1.51ml / min, will obtain more crack and uniform fine blue tungsten oxide particle.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Advantages

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:33

- Written by Cristina

- Hits: 382

Ammonium metatungstate, also known as AMT, is a tungsten chemical in the form of highly soluble hydrated crystals, solubility is 303.99/loogH:O when 20℃, aqueous fairly stable. It is white or slightly yellow crystals which has no harmful components and slightly acidic. It is being used more frequently with the development of tungsten industry.

Its great solubility can be matched into 1.3-2.1 aqueous solution which can meet the demand of tungsten containing catalyst. Normally in order to reduce diffusion resistance, tungsten concentrate in solution should be lower. When producing doped tungsten powder, tungsten concentrate should be higher which can be achieved through adjust, so that it can reduce heat exhaustion. During the producing process, ammonium metatungstate can be pyrolysised to obtain highly active pyrolysate. Doped tungsten trioxide made from this process can be used to conduct hydrogen reduction.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Influence Factors of Producing Blue Tungsten Oxide (1)

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:32

- Written by xiaoshan

- Hits: 321

With the development of science and technology, there are more stringent on quality requirements of blue tungsten oxide. The particle size and morphology of blue tungsten oxide are an important factor affecting the performance of it. After studies show that the raw materials and producing process are important factors affecting blue tungsten oxide particle size.

Firstly, the raw materials, if it has small particle size then using small raw material to produce blue tungsten oxide the particle of it will finer. Besides the blue tungsten oxide particle will more uniform.Secondly is producing process. The main factors which influence particle size is baking temperature, hydrogen flow and baking time and so on. Effect of baking temperature is at the beginning the crack will increase with the baking temperature increase, besides the rule crystal turn to irregularity small particle. But when the reaction reach to a certain degree the blue tungsten oxide particle crack will decrease with the temperature increase. While baking temperature at 400 ℃ blue tungsten oxide particles is uniformly but with the temperature rises, the uniformity of the particles is decline and the particles have grown.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Classes

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:31

- Written by Cristina

- Hits: 363

Ammonium metatungstate can be used as reagents for chemical analysis such as for chemical diagnosis; source material for the preparation of high purity tungsten trioxide used as a thin film substrate for certain semiconductor devices; high purity source material for research in tungsten chemistry; source material for DENOX catalysts industry; as a precursor to a variety of POM (polyoxometalates). Ammonium metatungstate applied in the manufacture of various petrochemical catalysts, It's the basic raw material of W-base catalyzer used in oil refinery.

It has different classes listed as below:

|

Class |

AMT-1 |

AMT-2 |

|

WO3(%) |

≥88 |

≥84 |

|

Water Solubility |

300g/100ml |

|

|

Fe |

0.002 |

0.005 |

|

Si |

0.002 |

0.006 |

|

Mo |

0.01 |

0.03 |

|

Cu |

0.001 |

0.001 |

|

M |

0.001 |

0.001 |

|

Mg |

0.001 |

0.001 |

|

Sn |

0.0001 |

0.002 |

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analyzing Blue Tungsten Oxide Appearance

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:30

- Written by xiaoshan

- Hits: 399

Learning blue tungsten oxide (BTO) phase morphology, size and uniformity, help to improve the performance blue tungsten oxide, so that it can be applied in more areas. To produce blue tungsten oxide is boat loading ammonium paratungstate (APT) to the hot zone and during the process to control the hydrogen flow, temperature and holding time these three parameters to produced blue tungsten oxide.

By using hydrogen reduction method to produce blue tungsten oxide and the surface of it has a large number of cracks and voids star, breakage obviously, it has lost the characteristics of hexagonal grains, forming a loose rule like appearance. Blue tungsten oxide surface has cracks is due to a large amount of water molecules and ammonium molecules which is produced from APT decomposition during the reaction. So the crystal inside of APT will cause inner stress to make crystal lattice mutation, resulting in cracks. At the same time, the external hydrogen to penetrate APT inside promoted deepening and expanding of cracks. Because of this crack APT generating vacancies and in baking time it caused partial intense contractions to make further fragmentation then to produce a fine particle powder.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

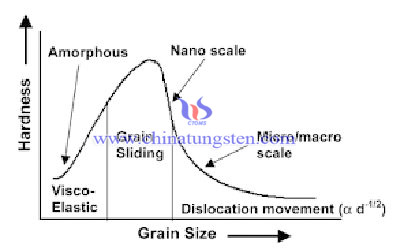

Tungsten Carbide Cutting Tools Grain Size

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 12:16

- Written by lucy

- Hits: 498

It is known that tungsten carbide hardness and toughness is affected by the WC grain size. For the finer grain size could be adopted in tungsten carbide cutting tools for light to medium-heavy roughing cuts, whereas the much tougher carbides- the coarse grain size over 8 μm, instead of cutting, they are applied in forming dies. In terms of medium grain size leads to a balance between hardness and toughness and are likely to be used for heavier rough cutting. Specially, if the grain size varies from 0.5μm to 1μm, it falls into micrograin carbides, with which the tungsten carbide cutting tools could offer more wear resistance, sharper cutting edge and better surface finish for hardened steels machining.

With nowadays cutting-edge technology, a hard tungsten carbide adopts using “ultrafine” WCpowder with less than 1% Co binder could offer moderate fracture toughness.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

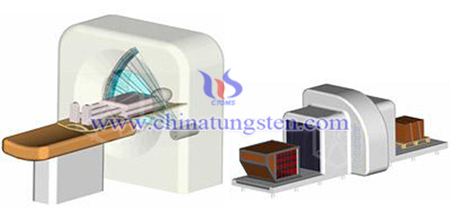

Tungsten Anti-Scatter X-Ray Collimators

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 09:56

- Written by wenjing

- Hits: 382

Tungsten anti-scatter collimators (also referred to as anti-scatter septa or grid), which is comprised by tungsten shielding, are used in CT X-ray equipment used for medical imaging, but also non-medical X-ray applications such as cargo scanners at (air)ports.

CT scanners consist of an x-ray source opposite an arc-shaped array of detectors. The collimator is located immediately in front of the detectors to protect them from scattered X-rays. Ideally, each detector in a CT scanner measures intensity of X-rays that reach the detector after traveling along a straight-line path from the X-ray source to the detector.

The commonly known tungsten anti-scatter collimator is comprised of thin plates formed from tungsten shieldling, which is suitable X-ray absorbing material. These tungsten plates are focused at the x-ray focal spot and generally located between columns of detectors (z-direction) but not between rows of detectors. This collimator is referred to as a "1D" anti-scatter collimator. In multi-slice scanners it has been found more advantageous to have shielding between both columns and rows of detectors; both directions are focusing to the X-ray source. This type is called a "2D" anti-scatter collimator.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com