Uses of Tungstic Acid-II

- Details

- Category: Tungsten Information

- Published on Friday, 26 June 2015 14:22

- Written by xinyi

- Hits: 391

Tungsten acid can be used for catalyst.

Catalysis is the increase in the rate of a chemical reaction due to the participation of an additional substance called a catalyst. With a catalyst, reactions occur faster and with less energy. Because catalysts are not consumed, they are recycled. Often only tiny amounts are required.

Catalysts can be heterogeneous or homogeneous, depending on whether a catalyst exists in the same phase as the substrate. Biocatalysts (enzymes) are often seen as a separate group.

Estimates are that 90% of all commercially produced chemical products involve catalysts at some stage in the process of their manufacture. In 2005, catalytic processes generated about $900 billion in products worldwide.

Tungsten powder Manufacturer & Supplier: Chinatungsten Online -www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Uses of Tungstic Acid-I

- Details

- Category: Tungsten Information

- Published on Friday, 26 June 2015 14:19

- Written by xinyi

- Hits: 382

Tungsten acid can be used for mordant.

A mordant is a substance used to set dyes on fabrics or tissue sections by forming a coordination complex with the dye which then attaches to the fabric or tissue. It may be used for dyeing fabrics, or for intensifying stains in cell or tissue preparations. The term mordant comes from the present participle of French mordre, "to bite". In the past, it was thought that a mordant helped the dye bite onto the fiber so that it would hold fast during washing. A mordant is often a polyvalent metal ion. The resulting coordination complex of dye and ion is colloidal and can be either acidic or alkaline.

Tungsten powder Manufacturer & Supplier: Chinatungsten Online -www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Insets with PVD Coatings (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 14:15

- Written by lucy

- Hits: 433

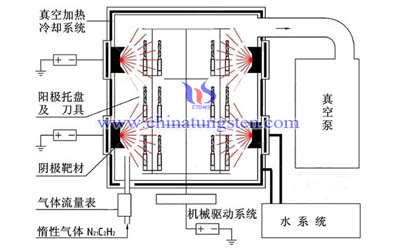

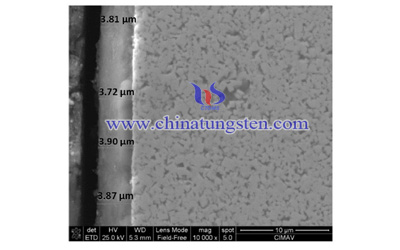

Physical vapor deposition (PVD) coatings are normally about 2-4 microns thick with hardness and chemical stable properties.

Generally the processes to help the tungsten carbide inserts to put on PVD coatings comprise, firstly the tungsten carbide inserts are required to be mounted on racks separately from each other. Besides setting the whole racks revolving within the vacuum furnace, each rack with the inserts is designed to expose every surface of the inserts is exposed to the deposition process. After that, a strong negative charge is applied to the inserts. Inside the vacuum furnace, there is a piece of titanium, or titanium and aluminum is installed on the wall or floor. The metal is vaporized by either an electric arc or an electron beam, liberating the positively charged metal ions. These ions are attracted to the negatively charged inserts. Nitrogen and methane are added as appropriate, to achieve the different types of coatings.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Insets with PVD Coatings (1)

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 14:15

- Written by lucy

- Hits: 356

Physical vapor deposition (PVD) coatings are normally about 2-4 microns thick with hardness and chemical stable properties. Tungsten carbide inserts with PVD coatings are well-suited to deal with nickel based, cobalt based or titanium based materials, sometimes even the materials like stainless steel and steel. In addition, in the application of high temperature cutting, the tungsten carbide inserts with PVD coatings also show advanced capability.

In nowadays coating technologies, the most acceptable PVD coatings for the tungsten carbide inserts include titanium carbo-nitride, titanium nitride and titanium aluminum nitride.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide AlCrN Coated Cutting Tool for Titanium Alloys (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 14:11

- Written by lucy

- Hits: 341

Tungsten carbide AlCrN coated cutting tool is a tungsten carbide cutting tool coated with a thin nano composite film made out of aluminum-chromium-nittride deposited by the PVD process.

Besides the improvement of tungsten carbide cutting tool’s wear behaviour, the AlCrN coating also presents low friction coefficients and wear rates,compared to normal heat treatment coatings. The tungsten carbide AlCrN coated cutting tool is revealed to have a wide potential tribological appliation under the sliding wear condition.

In terms of dealing with the titanium alloy in the machining or aerospace and biomedical components, with adequate process parameters, lubrication and other condition, the tungsten carbide AlCrN coated cutting tool is indicated to display acceptable levels of productivity and better wear resistance as well as better cutting performance due to the coating is mixed with high amounts of aluminum. Generally, the advantages include excellent properties at high temperatures, excellent antioxidation characteristics, as well as anti-spalling and debris removal properties for the contact interface.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide AlCrN Coated Cutting Tool for Titanium Alloys (1)

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 14:10

- Written by lucy

- Hits: 346

Titanium alloys are widely used in medical and aerospace components manufacturing, which are difficult-to-cut, and the requirements of parallel coated tungsten carbide cutting tools include high performance, enhanced tribological and resistance properties.

Tungsten carbide AlCrN coated cutting tool is a tungsten carbide cutting tool coated with AlCrN coating, which is a thin nano composite film made out of aluminum-chromium-nittride deposited by the PVD process. Since the heat treatment of AlCrN coating allows recrystallization and crystal growth the coated tungsten carbide tool’s wear behavior is enhanced.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Colloidal Tungstic Acid-IV

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 10:29

- Written by xinyi

- Hits: 383

The composition of the hydrosol has not been determined, but it is thought to consist of tungstic acid in combination with water, or possibly with sodium tungstate, since Sabaneeff obtained an amorphous powder, of composition Na2O.4WO3, from the dialysed solution.

When the solution is evaporated to dryness, transparent vitreous scales remain, strongly adherent to the crucible; on heating this residue to redness, the trioxide WO3 results. The aqueous solution has a bitter astringent taste; its density at 19° C. is as follows:

| Per cent. WO3 | 5 | 20 | 50 | 66.5 | 79.8 |

| Density | 1.0475 | 1.2168 | 1.8011 | 2.396 | 3.243 |

The gelatinisation of silicic acid is retarded by the presence of colloidal tungstic acid.

Tungsten powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Colloidal Tungstic Acid-III

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 10:26

- Written by xinyi

- Hits: 394

Colloidal solutions of tungstic acid, in presence of various organic reducing agents such as formaldehyde, sucrose, glucose, dextrin, etc., yield intensely blue solutions on exposure to light. If the solution is kept for some time, it does not undergo this reduction on being exposed to light; but on raising the temperature the blue reduction products are obtained. In order to account for this it has been suggested that two forms of colloidal tungstic acid exist, one being photochemically sensitive and the other not. The former changes spontaneously into the latter, the reverse change being brought about by rise in temperature, and the absorption spectra of the two modifications differ considerably.

Tungsten powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Colloidal Tungstic Acid-II

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 10:23

- Written by xinyi

- Hits: 388

The colloidal solution may also be prepared by dissolving tungsten tetrachloride in alcohol and ether (equal volumes) and then diluting with alcohol and water. The solution obtained acts as a positive colloid and coagulates immediately when small quantities of neutral salts, hydroxides, or strong acids are added. On passing an electric current through the solution, a deep blue precipitate separates at the cathode.

A hydrosol of tungsten hydroxide is readily produced by the electrolysis of a 2 per cent, solution of sodium tungstate between a mercury cathode and a silver anode in a Hildebrand cell. The solution must not be allowed to become acid, or blue compounds are produced. The hydrosols obtained in this way are clear and transparent but brown in colour. The addition of potassium chloride causes coagulation, a black powder, resembling the lower oxides of tungsten, being formed.

Tungsten powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Salts of Tungstic Acid-VII

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2015 10:11

- Written by xinyi

- Hits: 418

Such formulation suggests a closer relation to the metatungstates than appears to be justified, and would not account for the very essential differences between the two types of compounds.

Paratungstates gradually decompose in aqueous solution with formation of the normal and metatungstates, so that while a freshly prepared solution is neutral to phenolphthalein, it gradually becomes acid on standing - more rapidly on boiling. For this reason the electrical conductivities of the solutions slowly increase at ordinary temperatures.

According to Hallopeau the free paratungstic acid is formed in dilute solution when the barium salt is treated with dilute sulphuric acid. Concentration of the solution, even in vacuo, causes decomposition, and on prolonged boiling, metatungstic acid is formed. Alkalies neutralise the solution, yielding paratungstates. There is, however, no proof that this solution contains any special modification of tungstic acid.

Tungsten powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com