A Brief History of the Sport of Darts

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:14

- Written by yingying

- Hits: 341

A brief history of the sport of darts from the middle ages to today:

Early beginnings. The popular belief is that darts was created as a result of the boredom of being a warrior in medieval times. During downtime between battles, soldiers would challenge each other to games of throwing short spears at a thin slice of a felled tree. The age rings in the wood and the cracks that developed from drying created a simple likeness of a modern dart board comprised of multiple lines and many different scoring areas. The game became quite popular in the middle ages as it was used to keep soldiers’ throwing arms in practice.

A game for everyone. The sport of darts eventually became more widespread and even noblemen would be known to shoot a round from time to time. In fact, history shows that England’s King Henry VIII was given a set of darts as a gift. The game as we know it was in jeopardy of being changed over the years. People tried many different variations such as using a blowpipe to direct the dart. Some Scandinavians still play a version of darts by throwing foot long small spears from several yards away.

A game that almost never was. As it grew in popularity, the game of darts has defeated multiple attempts to have it banned. Many people believed that darts was a game of chance and not a game of skill, so it had to be settled in a courtroom in 1908. The game was banned in Scotland as a corrupt influence but the public outcry made it short-lived.

The modern game of darts. Today the sport is most popular in Britain where there are millions of players and thousands of registered clubs, however it's quickly becoming an international pastime. The game is popular in the Netherlands, Germany and the Scandinavian countries. In the U.S. hundreds of thousands of dartboards are sold every year and millions of Americans play darts every week.

With more and more people obsessed with dart sport, tungsten is the well-known material to make a perfect dart. Because tungsten darts is high-density and durable, in the mean time, tungsten darts also have fine knurling and worthy of being collective.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Advanced Strategies for 801 Tungsten Darts

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:09

- Written by yingying

- Hits: 326

The game of 801 Tungsten Darts is a test of your endurance. It is typically played with four players on one team. You can play it as a single-in, double-out or double-in, double-out. Here are some tips that can help you improve your chances of winning.

Stay focused on the game. With eight people throwing it can be easy to turn your focus away from the board between your throws. Make sure you have taken care of everything before the match, i.e. beer, smokes, bathroom break. Otherwise you run the risk of feeling anxious at the line because you took a break from the competitive atmosphere.

Beat your partners' throws. A fun game within the dart game of 801 is to try to beat the score of your partners who throw ahead of you. It’s a great way to stimulate the team to consistently throw high scores. Another idea is for each player to kick in one dollar before the 801 game starts and the person who shot the highest score wins the pot at the end of the match.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

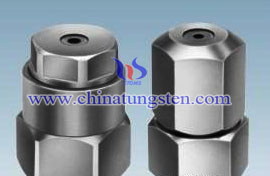

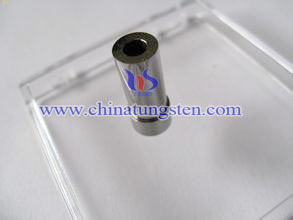

Tungsten Carbide Nozzle Distribution

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:03

- Written by xiaobin

- Hits: 307

Either tungsten carbide hollow atomizing nozzle, solid atomizing nozzle or fan-shaped nozzle, their basic principle is similar, which spraying taper angle starts in end face and enlarge horizontal size by the increasing axial distance. It has a great amount of nozzle that widely used in combustion equipments for cleaning, coating and lubricating in order to achieve the uniform distribution. Therefore, we should arrange tungsten carbide nozzle appropriately in case of improper atomizing distribution.

Theoretically, it is reasonable that arrange the distance of nozzle in accordance with annular and string-like under the equal condition, which contains spraying taper angle, atomizing quality, the flow and volume flux (the sample fluid volume pass through the detected area in unit time). However, the practical application is different from the theoretical data.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Reduce Abrasion Analysis IV

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:00

- Written by xiaobin

- Hits: 315

In addition, some experts expanding the length of nozzle to reduce the collision between grinding compound and inner wall of nozzle, which separates the core and the body and decreases the cost. There is a kind of structure design by American scholar, which is composed of penetrable stainless steel. What’s more, lubricant can pass through the media to adhere to inner wall of nozzle and build an oil slick layer after pressured. The oil slick layer will be supplemented by the pressure differential effect constantly after the erosion and shear of the grinding compound, which repairs the parts of erosion and shear wear and improves the concentration of beam of jet flow.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Reduce Abrasion Analysis III

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 16:58

- Written by xiaobin

- Hits: 314

At the present, the most widely used aspect ratio is 2:5. The experts design some unique structure nozzle to reduce the abrasion, such as tungsten carbide streamline nozzle with an arc entrance, tungsten carbide arc nozzle and tungsten carbide equal transmission nozzle. However, their processing is complicated and cost too much. A new style tungsten carbide nozzle, which take advantage of a step with angle to gather the most of grinding compound in center, which slow it down and reduce the abrasion in the area.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Reduce Abrasion Analysis II

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 16:56

- Written by xiaobin

- Hits: 332

Secondly, compared with the acceleration of water flow, the acceleration of abrasive particles is delayed during the movements in nozzle, which depends on the shape of nozzle, the size and density of grinding compound, etc. Due to the turbulence inside nozzle, the grains of grind compound has higher horizontal speed and collides with inner wall of nozzle, which leads to erosion and abrasion.

Therefore, a reasonable shape of inner wall of nozzle plays a significant role in reducing abrasion. There are two normal methods for reducing abrasion. One is to get a small aspect ratio in order to ensure that the entrance before the most badly wore area. And the other is contrary, which is to get a large aspect ratio to ensure that the entrance after the most badly wore area.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Porphyry tungsten Ore Deposit Occurrence in China

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 14:49

- Written by xinyi

- Hits: 453

Porphyry tungsten ore deposit occurrence in China

Lianhuashan mine in South China represents a new type of tungsten ore which can be described as a porphyry tungsten deposit. It is associated with a quartz porphyry stock of Yenshanian age (about 70–135 m. y.). The ore occurs in zone surrounding the contact of the quartz porphyry with Jurassic sandstone and extends into both rock bodies. The ore occurs either as the matrix of breccia or in the form of a very fine network of cross cutting veinlets. The major tungsten minerals are wolframite and scheelite associated with sulfide minerals of Mo, Fe, Cu, Pb and cassiterite. The minerals are fine-grained. There is zoned alteration in the wall rocks. From the center of the quartz porphyry toward the wall rocks one finds: potassic alteration, silicification-sericitization, and chloritization. All these features are similar to those of porphyry copper mineralization.

Fluid inclusion studies show three types of inclusion: liquid-rich (Type I), gas-rich (Type II), and polyphase with daughter minerals (Type III) fluid inclusions. The homogenization temperatures of Type I range from 210° to 380°C, with a salinity of 2–15 wt.% NaCl equiv., those of Type II from 270° to 420°C, and those of Type III from 240° to 400°C with a salinity of 31–33 wt.% NaCl equiv. The closely associated group of gas-rich and daughter mineral-bearing fluid inclusions homogenized at almost the same temperatures. Such results indicate boiling of oreforming fluids. These fluid inclusion data indicate that low salinity (Type I) and high salinity fluids (Type III) responsible for porpb yry copper deposits are the same as those for porphyry tungsten ore deposits.

These observations suggest that the Lianhuashan tungsten ore deposit is a porphyry tungsten deposit and was formed by hydrothermal fluids similar to those responsible for the well-known porphyry copper deposits.

Scheelite Deposits

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 14:31

- Written by xinyi

- Hits: 302

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Wolframite Veins

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 14:23

- Written by xinyi

- Hits: 326

Wolframite, including the tungstate of iron (ferberite) and the tungstate of manganese (hubnerite), has a field of occurrence similar to that of cassiterite. It appears in igneous rocks, in pegmatites, in cassiterite veins, and sometimes with quartz and bismuth minerals in veins which are evidently of the deep-seated type and allied to the tin veins. But, unlike cassiterite, wolframite also appears abundantly in veins formed under much more moderate temperature and pressure for instance, in those of Boulder County, Colorado. Small quantities of hubnerite are found in veins formed near the surface, as in those of Tonopah, Nevada, and Cripple Creek, Colorado. The principal production in the United States is derived from Boulder County, Colorado where the principal tungsten ore is ferberite, which occurs in small veins in granite. Hubnerite and wolframite have formed placers that are worked in the Little Dragoon Mountains, Arizona.

Wolframite veins of the deep-seated type have been described from the Deer Park district, in Washington and from sources in the Sierra de Cordova in Argentina. Wolframite lodes of great importance have lately been developed in the Tavoy district, These minerals are found in lower Myanmar, where they occur in granite and metamorphic schist and contain in addition quartz, mica, tourmaline, columbite, arsenopyrite, pyrite, bismuthinite and galena. At the same place wolframite is also recovered from alluvial deposits. In 1916 the mines of lower Myanmar produced about 3,000 tons of wolframite concentrates, which was about one-third of the annual output of the world. The crude ore is said to average 1.3 per cent. WO3 per ton.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Most Common Tungsten Ore Mineral

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 14:19

- Written by xinyi

- Hits: 340

The most common tungsten minerals are Wolfram, Hubnerite, Ferberite and Scheelite. They are all associated with the acid intrusive rocks, such as granites and pegmatites, rather than the ultra-basic rocks, like peridotite. Wolframite and hubnerite are by far the more important ore minerals of tungsten, scheelite being much less important. However, in the western US, sheelite has been the most common tungsten ore mineral. Wolframite and hubnerite constitute an isomorphous series. At one end of the series there is iron tungstate (FeW04) to which the name ferberite has been given; at the other end is hubnerite (MnW04). These two occur mixed in all proportions. Some writers use the names ferberite and hubnerite for the extreme types and wolframite for the intermediate types. Others recognize only two species in this series, one in which the iron tungstate predominates over the manganese tungstate (wolframite including ferberite) while in the other species (hubnerite) manganese tungstate is predominant. As in other isomorphous series of this kind, there is a gradation in physical properties, and in this particular case the color deepens and the mineral becomes more opaque as the percentage of iron increases. Tungsten minerals occur as lens shaped masses in the early segregation of an acid magma; in veins cutting acid intrusive rocks; in limestone, by metasomatic replacement; and as skarn deposits formed in contact metamorphic environments between limestone and acidic intrusive rocks.

Tungsten ore concentrates (chiefly wolframite) appear on the market in the form of concentrates, varying between 60 percent and 70 percent tungsten acid (WO3), and are purchased on the basis of their tungsten acid content. Seventy percent material is exceptionally good quality, and grades lower than 60 per cent, are saleable, but are subject to penalization. China is by far the world leader in tungsten production, having produced 56,000 tons of tungsten concentrate in 2009, which was 83% of the world output. Most of the remaining production originated from Russia (2,500 t), Canada (1,964 t), Bolivia (1,023 t), Austria (900 t), Portugal (900 t), Thailand (600 t), Brazil (500 t), Peru (500 t) and Rwanda (500 t).

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com