Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Retests

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 19:19

- Written by Yahong

- Hits: 304

If any test fails to meet the requirement, that test shall be repeated twice. The results of both retests shall meet the requirement. Specimen for retesting may be taken from the original test sample or from a new test sample. For chemical analysis, retests need only be for those specific elements that failed to meet their test requirement. If the results of one or both retests fail to meet the requirement, the material under test shall be considered as not meeting the requirements of this specification for that classification.

In the event that, during preparation or after completion of any test, it is clearly determined that prescribed or proper procedures are not followed in preparing the test specimen, or in conducting the tests, the test shall be considered invalid, without regard to whether the test is actually completed, or whether the test results meet, or fails to meet the requirement. That test shall be repeated, following proper prescribed procedures. In this case, the requirement for doubling the number of test specimen does not apply.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Chemical Analysis

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 19:18

- Written by Yahong

- Hits: 371

Chemical Analysis

Chemical analysis shall be performed on specimen of the electrode being classified. Any analytical technique may be used but, in cases of dispute, reference shall be made to established published methods. The referee method shall be ASTM F288. The results of the analysis shall meet the requirements of Table 1 for the classification of electrode under test.

Acceptance

Acceptance of the electrodes shall be in accordance with the provisions of AWS A5.01M:A5.01 (ISO 14344 MOD).

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Classification

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 19:17

- Written by Yahong

- Hits: 350

The following are several points on specification for tungsten and oxide dispersed tungsten electrodes for arc welding and cutting normative references:

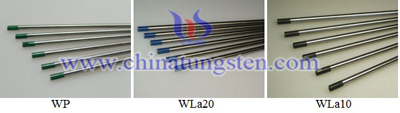

1. Classification of a tungsten electrode is based on its chemical composition.

2. The tungsten and oxide dispersed tungsten electrodes covered by this specification are classified using a system that is independent of the U.S. Customary Units and the International System of Units (SI). Classification is according to the chemical composition of the electrode as specified in Table 1.See Clause B7 for classification descriptions.

3. Electrodes classified under one classification shall not be classified under any other classification in this specification.

4. No electrode meeting the requirements of any other classification shall be classified under EWG.

5. The electrodes classified under this specification are intended for gas tungsten arc welding (GTAW), as tungsten arc cutting(GTAC), plasma arc welding (PAW), or plasma arc cutting (PAC), but that is not to prohibit their use with any other process for which they are found suitable.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Normative References

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 19:16

- Written by Yahong

- Hits: 1391

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies.

1. The following AWS standard (AWS standards are published by the American Welding Society, 550N.W.LeJeune Road, Miami, FL 33126) is referenced in the mandatory sections of this document:

AWS A5.01M/A5.01 (ISO 14344 MOD), Procurement Guidelines for Consumables – Welding and Allied Processes – Flux and Gas Shielded Electrical Welding Processes

2. The following ANSI standard (The ANSI standard is published by American Welding Society, 550N.W.LeJeune Road, Miami, FL 33126) is referenced in the mandatory sections of this document:

ANSI Z49.1, Safety in Welding, Cutting, and Allied Processes

3. The following ASTM standards (ASTM standards are published by the American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, PA 19428 - 2959) are referenced in the mandatory sections of this document:

ASTM E 29, Standard Practice for using Significant Digits in Test Data to Determine Conformance with Specifications

ASTM F 288, Standard Specification for Tungsten Wire for Electron Devices and Lamps

4. The following ISO standard (ISO standards are published by the International Organization for Standardization) is referenced in the mandatory sections of this document:

ISO 31 – 0:1922, Quantities and Units – Part 0: General principles; and Annex B, Rule A

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Scope

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 19:14

- Written by Yahong

- Hits: 310

This standard specifies requirements for classification of non-consumable tungsten electrodes for inert gas shielded arc welding, and for plasma welding, cutting, and thermal spraying.

This specification makes use of International System of Units (SI) and the U.S. Customary Unites. The measurements are not exact equivalents; therefore, each system must be used independently of the other without combining in any way when referring to material properties. The specification designated A5.12M uses SI Units; and the specification designated A5.12 uses U.S. Customary Units. The later units are shown within brackets or in appropriate columns in tables and figures. Standard dimensions based on either system may be used for sizing of tungsten electrodes or packaging or both under A5.12M or A5.12 specification.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Abstract

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 19:06

- Written by Yahong

- Hits: 329

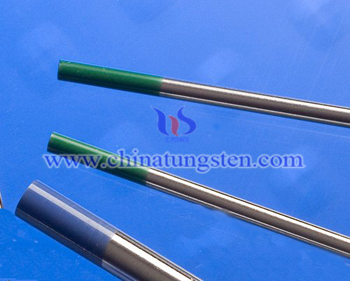

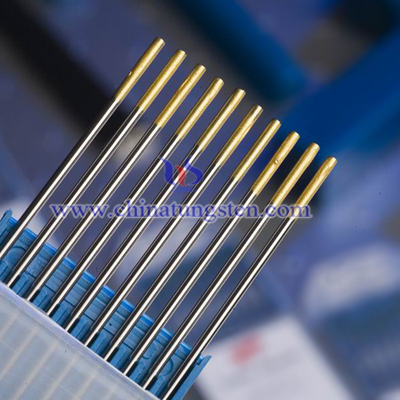

This specification prescribes the requirements for the classification of bare tungsten and oxide dispersed tungsten electrodes for gas tungsten arc welding and cutting and plasma arc welding and cutting. Classification is based on the chemical composition of the electrode. Standard sizes, finish, lengths, quantities, product identification, color coding, and chemical composition limits are specified.

This specification makes use of both U.S. Customary Unites and the International System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

This specification adopts the requirements of ISO 6848:2004 and incorporates the provisions of earlier versions of AWS5.12, allowing for classifications under both specifications.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Venturi Nozzle Used in Shot Peening III

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 17:19

- Written by xiaobin

- Hits: 281

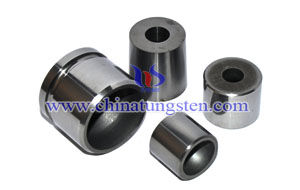

Tungsten carbide venturi nozzle has excellent uniform distribution of grinding compound. It is different with common straight type nozzle, which gathers the most of grinding compounds in the center of divergent area and narrow effective clean-up width, tungsten carbide venturi nozzle has wider effective clean-up width, more uniform grinding compound force. So that it can obviously improve the efficiency 15%--40% and reduce the consumption of the grinding compound.

In addition, there is a unique two-venturi nozzle, which has two nozzles at front and rear. Besides, there are some pores between two nozzles. Under the circumstances, it inhale surrounding air and make the volume of spraying is larger than the compressed air to accelerate the speed of grinding compound output. This diameter of two-venturi nozzle exit is longer than tungsten carbide venturi nozzle, smaller impulsion and 35% diverging area larger than normal nozzle so that the efficiency is improved.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Venturi Nozzle Used in Shot Peening II

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 17:17

- Written by xiaobin

- Hits: 302

Tungsten carbide venturi nozzle structure can be divided into three parts, which is straight segment, shrinking segment and diffusion segment. So its process is more complicated than common nozzle. In terms of gas dynamics performance, tungsten carbide venturi nozzle is better than straight type nozzle, which has low pressure loss, improves vortex phenomenon. Under the same pressure, the speed of grind compound entrance can be up to 1 times higher than the normal, even close to the speed of sound. Therefore, the kinetic energy of the grinding compound has been remarkably improved, the impact has been significantly strengthened, which enhance the efficiency of tungsten carbide venturi nozzle and reduce the cost of production.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Venturi Nozzle Used in Shot Peening

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 17:15

- Written by xiaobin

- Hits: 336

Shot peening process is similar to sandblasting processing, the only distinction is grinding compound is different and shot peening needs more air pressure. It is widely used in surface strengthen, polishing and deoxidation to eliminate forging residual stress which requires simple equipment, lower cost and not limited by the shape of material and the space. Shot peening materials contains cast iron balls, steel balls, glass balls and pottery balls, and the glass ball has high requirements, which should be above 6-7 Moh’s hardness. Otherwise, it will be fragile under high-speed impact and increase the cost. After shot peening process, the material will be harder, tougher and has better anti-corrosion and fatigue strength, extends their lifespan.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Deep Cryogenic Technology III

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 August 2015 17:12

- Written by xiaobin

- Hits: 332

Tungsten carbide nozzle is mainly composed of WC hard phase and Co binder phase. It is essential that hard phase ensure the high hardness, toughness and good heat resistance. While the binder phase has a polymorph characteristic, and usually plays a very important role in physical and chemical action in cemented carbide sintering process. X-ray diffraction analysis showed that the grain within tungsten carbide has structural change and increases the number of sub-grain boundaries per unit volume.

The sub-grain boundary structure is unique, which will enhance the shear stress plastic deformation resistance of the alloy so that the plastic deformation of tungsten carbide becomes difficult. Therefore, changes in internal microstructure reflected in the macroscopic properties change is to improve the ability of anti-abrasion synthetic polymers as well as its own resistance to abrasion, erosion resistance and service life have been significantly extended.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com