Tungsten Carbide Inserts: Leaping Development of Manufacturing Field

- Details

- Category: Tungsten's News

- Published on Wednesday, 21 September 2016 11:09

- Hits: 690

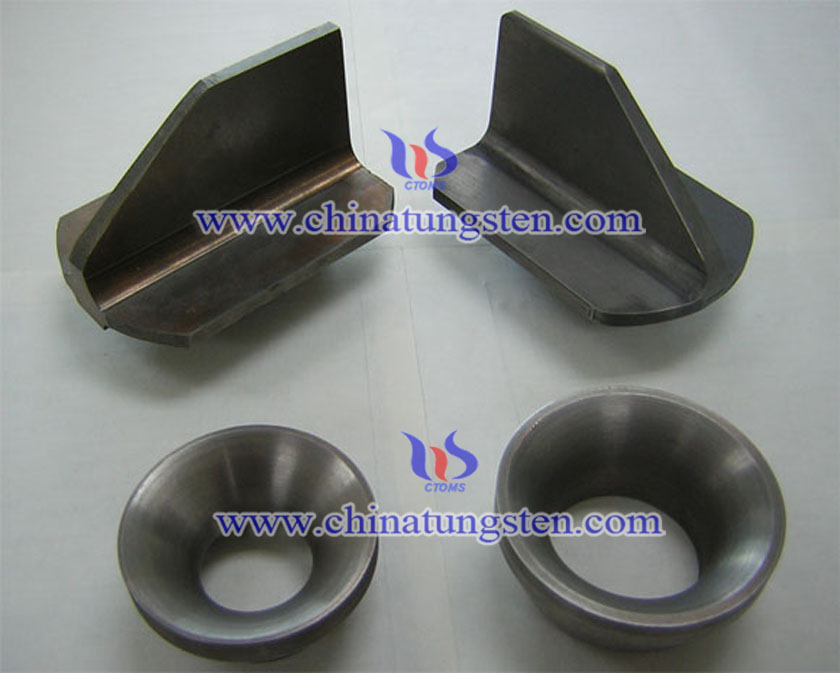

Tungsten carbide is a very high hardness materials, cutting tools are mainly used in metal cutting has been widely used. In the machinery industry, mentioned alloy steel or tungsten carbide generally refers to such materials. Carbide cutting tools can be harvested many advantages. Compared to high speed steel cutting tools, in most cases, the use of carbide cutting tools can be harvested only workpiece surface quality is better, but also to obtain higher processing speeds; Carbide Tool can withstand higher cutting heat, which is that it can achieve a higher metal removal rate of the main reasons. When the workpiece machining high-alloy steel or stainless steel such easy processing, or in mass production and capacity expansion of the occasion, a case such as high-speed steel cutting tool wear easily and quickly, using conventional carbide tools can make cutting performance better.

Tungsten carbide cutting tools for metal cutting industrialization began in the nineteen thirties. Since then, it has evolved into carbide by far the most common tool materials. The relatively small size of carbide cutting tools are often made of a whole; only non-solid carbide cutting tools with carbide in the cutting area. Early non-carbide solid carbide tools tend to be welded to the cutter body. To the 1940s, carbide cutting tools manufacturers began producing holding interchangeable machine folder blade cutter, and benefit. Compared to the earlier welding tool, this brain-hole wide open to technological innovation and the use of mechanical clamping structure makes the tool more strength, which has now been recognized as a landmark invention, not only in the field of tool manufacturing further comprising bringing advanced and efficient process for the entire metalworking industry.

The considerable progress in the field of manufacturing opened up vast room for improvement, and immediately increase the carrying capacity of the tool, the tool has the ability to make rapid removal of metal. Replace the blade becomes more simple and cost reductions made to protect the economy, but also makes it possible to separately manufacture cutting module and the cutter body except for the blade failure due to wear or breakage failure. Replace the blades often need to consider the shape, quickly replace the failed cutting edge in several ways, in addition to the blade along the central axis indexing, there are also cases reversed blade front and back. Today, the most recognized industry wide dissemination of "indexable" the title, once also known as: the disposable tip, replaceable blade, replaceable blade.

Tungsten carbide indexable insert production technology based on powder metallurgy technology, the production process is as follows: Preparation of carbide mixture, pressing, sintering, sintering treatment step and coating. Despite decades or more basic process remains the same, but at the same time from the progress of science and technology but then blade manufacturing had a significant impact.

Until the 1980s coated carbide grade has not yet appeared. At that time, such that carbide can be common to the processing of different engineering materials, tool manufacturers by adding different additives (such as a hard phase or a metal additive) to the preparation of different carbide grades. Coating technology adoption has greatly promoted the development of the global machinery industry; the vast majority of today are coated carbide grades. This new technology also brings additional benefits, so some special grades can be processed a certain class of materials to be processed. You do not need to add many kinds of cemented carbide substrate additives; This reduces the cemented carbide substrate grades, production process control more stable.

PVD coating in the late 1980s is introduced into the carbide production. PVD coating because at the nanoscale coating areas to overcome the manufacturing of many problems to achieve a breakthrough in the development. PVD coating thus providing a new level of higher wear resistance nano-coating. Compared to conventional PVD coating manner coating as shown by a maximum of 50 nm (nanometer) coating composite, it has been shown to greatly improve the binding strength of the coating.

Tungsten carbide blade production progress technologies from several areas of development. More cutting-edge technology of pressing, sintering technology, coating technology and post-coating technology, more diverse surface treatments can be carried out on the cutting edge of the blade more optimized manufacturing process together make indexable inserts can provide modern metal processing industry to provide more suitable to meet their needs efficient processing solutions.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Nano Plate Catalyst to Improve Solar Energy Conversion Efficiency

- Details

- Category: Tungsten's News

- Published on Sunday, 18 September 2016 14:55

- Hits: 800

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide International Fair will be Unveiled at Shanghai

- Details

- Category: Tungsten's News

- Published on Tuesday, 13 September 2016 18:07

- Hits: 773

Tungsten carbide 2016 Shanghai International Expo area of 30,000 square meters, is expected to reach more than 500 domestic and foreign exhibitors, professional audience of 30,000 people attended the Shanghai International Expo tungsten carbide is the tungsten carbide areas set product launches, technology exchange and business cooperation in one of the professional event.

1. The establishment of an international brand exhibition, high-tech products, technology, the first to release

Many well-known manufacturers at the show site will publish new equipment, new technology, new materials, allowing you to buy better assessment; open the current Shanghai International Expo Exhibitors List Tungsten carbide, we clearly feel Shanghai International Hard alloy Expo brand cohesion remains unsurpassed: Chinese and Japanese Han Qicheng more than well-known brands, as well as a growing number of overseas famous brand in here, both industry leaders, have extraordinary potential rookie. Include: Kim Shin Zigong, Zhuzhou Lihua, accessible Zhuzhou, Zhuzhou Maoxiang, Zhuzhou Kim Shin, Xiamen Tungsten, Jiujiang spoonbills, Renqiu forward, Shanghai Grand Holcim law, Yueqing source, the Shanghai Research Institute of Materials, Jinan metallurgy Sciences Co., Ltd., Hai Keli special alloy tool and die development Co., Ltd., Taiwan and the United States Yang technology, Xin Matilda, Hunan Dingli technology Co., Ltd., Weihai Wei hard, German PTV, Chen Hao Shanghai composite materials Co., Ltd., Shenyang Heng Jin vacuum Technology Co., Ltd. SGL specialty graphite (Shanghai) Co., Ltd., France Kay Pu Technology Group Shanghai office, Shanghai Oriental carbon Co., Germany Conner KonradFriedrichsTungsten carbide (KFC), Tokai carbon Yao and many other well-known enterprises.

2. "Three Exhibition Linkage" comprehensive interpretation of the metal processing industry chain event

2. "Three Exhibition Linkage" comprehensive interpretation of the metal processing industry chain event

Shanghai International Expo tungsten carbide through continuous upgrading of hardware and software, to optimize the structure of display, in October this year the show will be a new attitude in full bloom, become more popular Tungsten carbide industry event! Tungsten carbide Shanghai International Expo, Shanghai International cutting tools and equipment Exhibition and Shanghai international Exhibition abrasive grinding processing technology exhibition three linkage, will be held in Shanghai World Expo Exhibition October 11.

3. Professional forum the industry heavyweight mystery guest to visit the site

Over the same period will be held 2016CCME finishing Technology Forum and Shanghai International abrasive grinding technology seminars, conferences and adhere to the public nature of dry-based technology, is committed to providing various forms of flexible integration to share trends, the development of Internet technology and the latest developments, assess the latest trends in technology and operations; for technical, research and development personnel, business operators to explore new ideas, look for effective research.

4. 300 domestic and foreign media, broadcast throughout the show dynamic

Shanghai International Expo tungsten carbide and tungsten carbide gathered 300 domestic user industry media reached a strategic cooperation to form a public authority magazines, newspapers, websites, television in one powerful propaganda line-up, with the professional league to reach interactive media, publicity and promotion efforts Show information, to achieve aggregation of dissemination of information, to attract more audiences and downstream industry professionals attending the event, exchange, purchase.

Tungsten carbide 2016CCME Shanghai International Fair will be adhering to the "professionalism, effectiveness, quality, service" four exhibition service standards, more effort to build the field of Tungsten carbide exclusive event.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Incandescent Lamp Ending, LED Lamp New Era

- Details

- Category: Tungsten's News

- Published on Monday, 12 September 2016 18:41

- Hits: 1217

In China, eyes of the night over several decades, incandescent lamps announce its ending on Oct. 1, 2016. The announcement of “China Phases out Incandescent Lamp Timeline” by Development and Reform Commission of the People’s Republic of China says China will forbidden import and sale incandescent lamp over 15W since Oct. 1, 2016.

I Incandescent lamp phasing out timeline

Nov. 1, 2011 ~ Sep. 30, 2012

Transition period. The importer, seller shall be prepared working on elimination in accordance with the requirements of the government.

Oct. 1, 2012

The importing and selling of incandescent lamps over 100W are forbidden.

Oct. 1, 2014

The importing and selling of incandescent lamps over 60W are forbidden.

Oct. 1, 2015 ~ Sep. 30, 2016

Mid-evaluation period, based on the preliminary policy evaluation, the adjustment policy will be issued.

Oct. 1, 2016

The importing and selling of incandescent lamps over 15W are forbidden.

II Policy issuing

In Second half of 2006, the International Energy Agency released a report on the global lighting energy use noted that in 2005, total consumption of incandescent power terminal is 970 billion degrees, accounting for 37% of the global lighting electricity, equivalent to the carbon dioxide emissions of about 5.6 one hundred million tons. If the lamp phases out since 2008, it saves 38% of electricity for lighting until 2030, equaling to the cumulative reduction of 16.6 billion tons of carbon dioxide emissions.

Australia has been the first country to issue incandescent lamps phasing out plan in Feb. 2007. New Zealand, Germany, Portuguese and other tens of countries are put forward the same plan. So is China in 2011.

III LED lamps taking over incandescent lamps

LED lamp and energy-saving lamps have taken over the ineffient lamps and have been the main force in lighting industry. The manufacturing cost has been decreasing a lot since 2011 for the increasing quantity used in families. In order to improve the use of LED lamps, government subsidies, discount provided, offered as premiums. Hard work pays off. The LED use rate is going up from under 10% in 2011 to 32% in 2015. it is expected to be 50% in 2020.

IV Will Incandescent lamps over filaments

Incandescent lamps are one of the main applications of tungsten filament. However, the ending in China will promote the exporting of filaments and lamps. Meanwhile, tungsten wire will create its new application areas, but not limits in inefficient lamps.

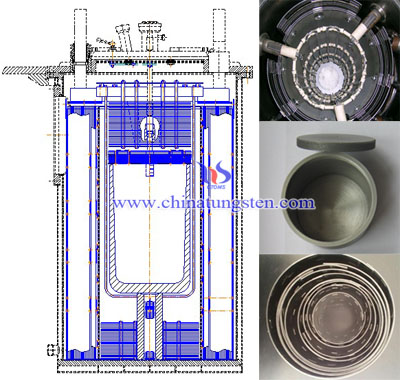

V Popular use of LED will increase the apply of tungsten and molybdenum products

Due to the universal of LED lamps, the furnace to growing LED sapphire wafers consumption will increase to a new high. At the same time, tungsten and molybdenum products, including crucibles, heating elements, heating field, sheet shield, will be required in a large number. Thus, an ending era of incandescent lamps is a new start for tungsten and molybdenum materials.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Warhead Pushes R& D of Loitering Missile

- Details

- Category: Tungsten's News

- Published on Wednesday, 07 September 2016 18:28

- Hits: 1511

The new concept of ammunition is one type of organic combined products from UAV (Unmanned Aerial Vehicle) technology and ammunition technology, which has strike, correspondent, target, monitor and other air alert functions.

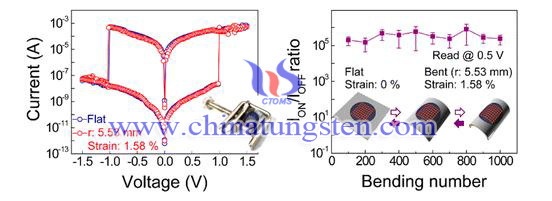

Latest Research for Non-volatile Memory Device Uses WO3

- Details

- Category: Tungsten's News

- Published on Wednesday, 07 September 2016 15:48

- Hits: 928

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

China Only Spends $6 Billions on 14 Rockets

- Details

- Category: Tungsten's News

- Published on Tuesday, 06 September 2016 16:04

- Hits: 1297

China's new generation carrier rocket "Long March VII"; in at 20:00 on June 25, 2016 the entire spaceport Wenchang in Hainan successfully launched. Long on the 7th is the near-Earth orbit carrying capacity of China's largest rocket, its first flight as China's manned space project Spacelab mission phases starting gun, flush China Aerospace multiple records, opened a new chapter in China's rocket development.

June 25, Beijing time 20:00 sharp, a bright orange light pierced the darkness shrouded in Hainan Island, along with the roar of the engine, a 53 m long rocket into the sky.

In the past few years, the number of rockets launched by China increased significantly, but this rocket because of four reasons unusual. Firstly, it is the Long March series VII first rocket, the Long March rocket VII advent to carry with multifunction cabin space station to orbit. Secondly, since it is built in Wenchang, Hainan Cosmodrome launch of the first rocket. Hainan Wenchang launch site will become China's future space exploration space program base. Again, rocket engines using tungsten copper nozzle . Finally, this is the first rocket to visitors disclosed.

In this sultry June evening, thousands of people gathered in the center of the large for viewing platform launch, a much-anticipated rocket into the sky. Rockets Yiqijuechen cheers of the crowds, began its 394 km above the surface of the journey.

Tungsten copper alloy used in the aerospace missile, rocket engine nozzle, gas vane air rudder, the nose cone, the main requirements are high temperature (3000K ~ 5000K), high-temperature airflow flushing capacity, the use of copper at high temperatures the formation of volatile cooling sweat role (copper melting point 1083 ℃), reducing the surface temperature of tungsten and copper, to ensure use in high temperature extreme conditions.

Below is tungsten copper nozzle at the bottom of the rocket detail drawings .

"China is becoming an important space power", the project of the European Space Agency (ESA) under the Council for Science Coordination Office Fabio • Fawei Ta representation.

Rocket pictures

August 16, China at the Jiuquan spaceport launched the world's first quantum communications satellite "Mo Number." US and Russian experts say, quantum communication is the best choice to ensure information security and defense hackers. "Mo Number" is a phenomenon of quantum entanglement satellite. Quantum entanglement obscure abstruse problems, and even Einstein chanting "Just Like Ghostly."

China's annual spending on space projects expected to be about $ 6 billion, although more than Russia nearly $ 1 billion, but still far less than the $ 40 billion the United States. Although the United States in the space program ho throw tens of billions, but in 2013, only the United States successfully launched 19 rockets; the same year, China launched 14, Russia launched 31. From the data, China clearly has a place in space, and in the future will only grow stronger.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Market Off Season Ended, Indicative Price Coming Soon

- Details

- Category: Tungsten's News

- Published on Monday, 05 September 2016 18:41

- Hits: 684

Tungsten market off season ended last week, the flowing trend is unobvious, market is in an intensive situation. Demand still doesn’t increase. Tungsten market volume of business keeps decrease, most enterprises hold wait and see attitude for tungsten market.

Tungsten market not only needs demand but also stability of market. Last week, some enterprises sell the price below market level which is challenging the confidence of market. However, volume of business is still small.

Last week, tungsten products price changes originates from ammonium paratungstate, the mainstream enterprises maintain stable quotation. Some large metallurgy factories say that due to the cost of raw material, ammonium paratungstate price won’t decrease in the next few weeks. APT quotation stays 105~107 thousand RMB/ton. Some other enterprises show that they have advantages both in raw material cost and manufacturing cost. In order to sell the product intiative, quotation maintains at 103~105 RMB/ton, but the selling amount is negative.

Today the indicative price by Ganzhou Tungsten Industry Association, China Minmetal and Jiangxi Rare Earth and Rare Metals Tungsten Group Corporation will come out. It will indicate market price and keep the mainstream stay positive. The indicative price is mainly based on support market confidence, it will be a bit higher than spot market.

The future market trend will greatly depend on this week. It will either turn splendid or fade away. Break weak balance of market is easy, but there is no one who will intervene market balance. Although supply and demand are the most important factors, tungsten price is already below the cost level which is unchangeable. We predict that in short times market will turns weaker and stay stable in the whole as a whole. Dynamic of large enterprises is a key to market, once the stimulus appears, to promote and develop the market is not difficult.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Greenest Shanghai Tower May Use Tungsten Trioxide

- Details

- Category: Tungsten's News

- Published on Monday, 05 September 2016 11:15

- Hits: 675

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Breakthrough of Chinese Scientists - Let Liquid Metal Machine Run, Jump

- Details

- Category: Tungsten's News

- Published on Friday, 02 September 2016 17:42

- Hits: 957

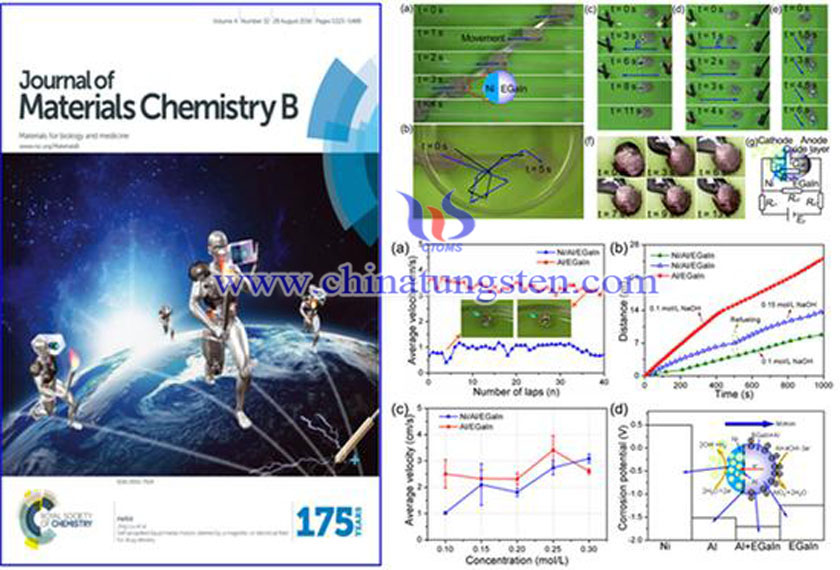

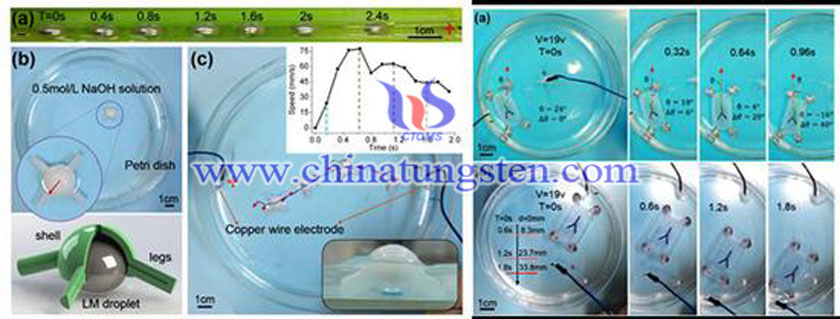

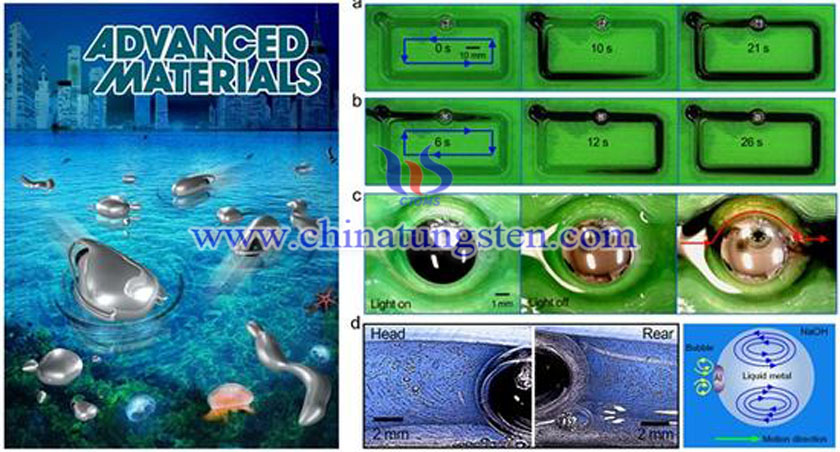

In 1991, the movie "Terminator 2" appears in a powerful robot T-1000, the use of liquid metal to create a robot no matter how much harm can be met with an instant automatic recovery, and even can change the body shape and facial appearance. This deformation robot scientist has always been one of the goals, and now, a study by Chinese scientists in the field of liquid metal eligible for a breakthrough in the long road of research and a small step forward. New research allow liquid metal machine can "run" can "jump".

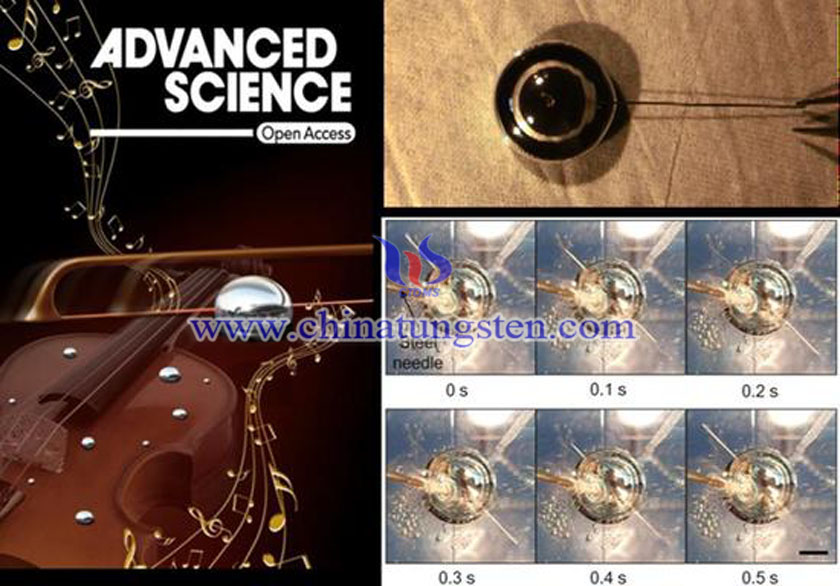

Liu Jing team research group reported an unusual unique self-oscillation effect of liquid metal solid-liquid combination machine: when the tungsten copper wire touches treated aluminum-containing liquid metal, tungsten copper wire are quickly swallowed by the liquid metal, and then made a long shuttle back and forth movement of the liquid metal in the body, like playing the violin string music in general.

Tungsten copper wire with heat ablation resistance, high strength, electrical conductivity and other characteristics.

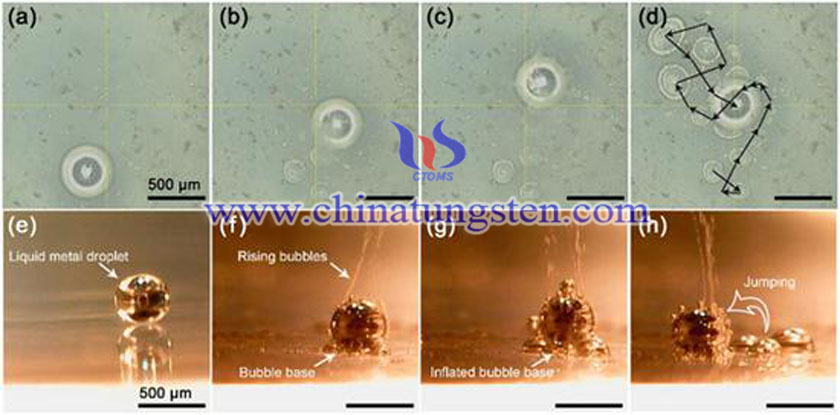

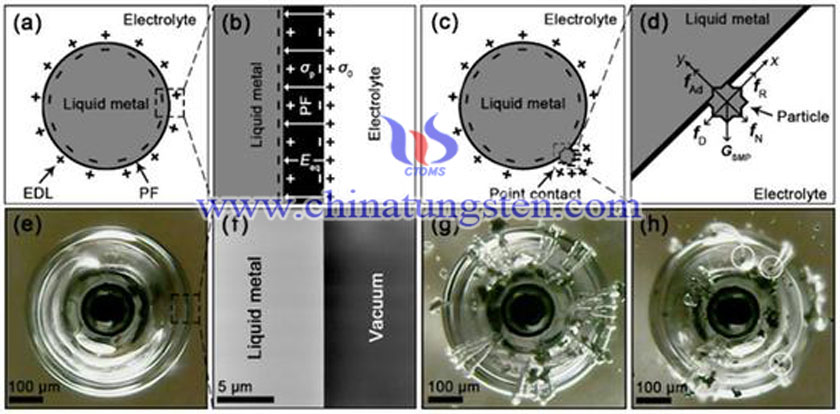

The authors found that a class of interesting liquid metal jump behavior: There is added to the discharge of solid metal particles (tungsten, nickel, copper, iron, etc.) solution system of metal droplets, the original stationary metal droplets began to beat up and leaving a string of cake in the bottom of the container "footprint."

Research revealed that the surface of the metal particles and liquid metal point contact occurs when the electric field strength at the interface significantly enhanced, as well as in the solution within the electrolysis hydrogen production, hydrogen bubbles are formed in the substrate continues to grow adsorption "gas spring", which droplets jump provide thrust. One of the factors leading to the electric field polarization between the liquid metal from the metal particles with solid potential difference that is galvanic effect; the other reason is that the solid - liquid material microstructure differences between the interface will lead to charge accumulation, sparking tip discharge effect.

Research team by a plating method in the liquid metal surface mount ferromagnetic nickel layer, thereby realizing flexible control of the machine in an external magnetic or electric field and verify its potential value in terms of drug delivery. Beyond the random motion of the liquid metal type machine it is that the magnetic solid-liquid combination can be achieved from the machine stop motion, steering and acceleration of complex behavior.

Furthermore, the team also developed a kind of flexible deformable "wheels" driven miniature vehicle, its body is made of plastic and metal droplets through a combination of 3D printing. In the electric field, the liquid metal "wheel" can rotate deformed, and then drive the vehicle travels, and even accelerate the realization of more complex motion.

Liu Jing study team found that in the electrolyte, a liquid gallium based alloy, after "swallowing" Aluminum as food or fuel, can actually deformed shape long high-speed motion machine to achieve without external power autonomy movement.

In recent years, Liu Jing team has been working to promote joint industry liquid metal industrial applications. She said: We have the opportunity to study in the liquid metal in the world to go ahead, but can not lag behind in terms of industry, we need to seize the historic opportunity to help build our country into a world-class liquid metal valley.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com