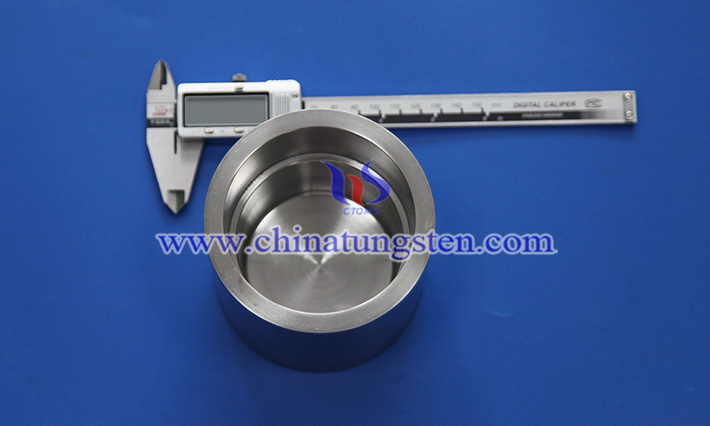

What Are the Main Properties of Tungsten Crucible?

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 April 2025 15:00

The main properties of tungsten crucible include high melting point, high temperature resistance, excellent corrosion resistance, good thermal shock stability, and high strength and stability.

1. High melting point and high temperature resistance

Tungsten has a high melting point of 3422°C, which is one of the highest melting points in nature, which allows crucibles to operate reliably in extremely high temperature environments. For example, during the growth of sapphire single crystals, the temperature in the furnace often exceeds 2000°C, and the crucible can withstand such high temperatures without melting or deformation. In addition, the crucible exhibits excellent stability in vacuum or inert gas environments, avoiding high-temperature oxidation problems. This resistance to high temperatures makes it ideal for high-temperature melting (such as high melting point metals such as titanium, zirconium, etc.) and for the preparation of semiconductor materials.

2. Excellent corrosion resistance

Tungsten crucibles have excellent corrosion resistance to a wide range of chemicals, especially in the smelting of rare earth metals. Rare earth element melts are usually highly corrosive, and tungsten can effectively resist the erosion of these melts and extend their service life. In addition, tungsten crucibles can maintain structural integrity in high-temperature chemical reactions or acid-base environments, reducing chemical reactions with melts and ensuring material purity. This is particularly important for the preparation of high-purity materials, such as in the semiconductor and photovoltaic industries.

3. Good thermal shock stability

Thermal shock stability refers to a material's ability to resist cracking or breakage under rapid temperature changes. The W crucible needs to withstand rapid heating and cooling from room temperature to more than 2000°C in high-temperature cycles. Tungsten's low coefficient of thermal expansion and good thermal conductivity make it less prone to cracking under thermal shock. This performance is particularly critical in high-temperature experiments and vacuum heat treatment.

4. High strength and mechanical stability

The crucible retains high mechanical strength at high temperatures, avoiding deformation caused by external force or thermal stress. Its high hardness and creep resistance make it less susceptible to deformation or failure during long-term high-temperature operation. For example, in the melting process of aerospace superalloys, the W crucible is subjected to complex stresses, and its high strength ensures process stability. In addition, the manufacturing process of tungsten crucibles, such as powder metallurgy or plasma spraying, further optimizes its microstructure and improves the overall mechanical properties.

5. Thermal conductivity and heat transfer performance

Tungsten has a high thermal conductivity (about 173 W/m·K), which enables the W crucible to conduct heat quickly in high-temperature environments and achieve uniform temperature distribution. This is especially important for single crystal growth and high-temperature melting, as a uniform temperature field improves crystal quality and melt consistency. At the same time, the thermal conductivity of the W crucible helps to reduce the thermal stress concentration and extend the service life.

6. Other Features and Limitations

Tungsten crucibles also have the characteristics of high density and low vapor pressure, which is suitable for use in vacuum environments and reduces volatile pollution. However, it also has some limitations, such as difficult processing, high cost, and easy oxidation in certain oxidizing atmospheres. To overcome these problems, modern processes often employ surface coating techniques such as alumina or zirconia coatings to enhance their oxidation resistance or to optimize performance by doping trace elements.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com