Ag-WC-C Contacts Material

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2015 15:53

- Written by Yahong

- Hits: 359

Ag-WC-C contacts material has been gradually replaced AgC5 contact material, because its excellent physical properties is better than the latter’s and it can reduce the use of silver material and saving cost. Ag-WC-C contacts material is mainly making use of the properties of good thermal conductivity and electrical conductivity of Ag and the properties of high hardness, high melting points and wear resistance of WC, which has been promoting the use, mainly used in electrical switches, such as, large capacity circuit breakers, molded case circuit breakers and automatic switches.

Traditional Ag-WC-C contacts preparation method is usually adopting powder metallurgy method --- pressing the mixing powder directly in the mold after mixing silver powder, tungsten carbide powder and additives, and then the contacts can get by sintering and forging and other processes. The advantages of using the process to prepare the kind of contacts are: simple process, easy operation and low requirements for equipment and lower production costs; disadvantages are: the contact material is defective prepared by this process, for example, its density is poor, organization is not even, and arc erosion resistance is poor and so like.

In the on-off process, Ag-WC-C contacts often due to material melting, arc erosion or splashing, making the generation of tungsten trioxide, silver tungstate and some other non-conductive compounds on its surface, leading to the increase of contact resistance, resulting in contact surface temperature increasing greatly, and ultimately affect the on-off performance of contact.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Reliability Research on Tungsten Contacts

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2015 15:51

- Written by Yahong

- Hits: 385

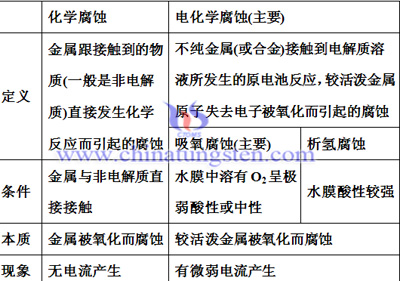

1. The dark brown gum on tungsten contacts surface is --- H2WO4 (which can be dissolved in water, its aqueous solution is gray, after dewatering, it would turn into brown oxide dura --- WO3) is a compound which is generated by electrochemical corrosion under high temperatures and high humidity conditions.

2. The root causes of electrochemical corrosion: the potential difference (0.54V) between contact wafer (tungsten) and the base (copper) is larger.

Electrochemical corrosion refers to a corrosion galvanic cell, in which metal and electrolyte act as an electrode composition.

Deoxygenating methods: the common deoxidize methods of vacuum, heating powder, iron scrap, resin and chemical agent methods.

3. In order to improve the reliability of the contact of tungsten contacts

(1) Minimize the electrode potential difference between the contact wafer and the copper base. Under normal weather conditions, the contact potential difference between the electrodes can not be more than 0.5V; in bad weather, can not be greater than 0.25V.

Electrode potential refers to, in the electrolyte solution (water), there are potential difference generated between the metal (tungsten) surface and the solution, that is, the electrode potential of the metal in the solution.

(2) The combination of W and Ni or tungsten-rhenium 10 - nickel, then weld them into contact, can improve the reliability of tungsten contacts, which can prevent the formation of oxide film on tungsten contacts surface.

4. When the load current is not very large, use other materials, such as silver and copper, to take the place of tungsten as a contact.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Processing

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2015 12:31

- Written by xinyi

- Hits: 356

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effect on Tungsten Polymer Injection Molding

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2015 12:52

- Written by wenjing

- Hits: 335

Tungsten polymer is a composition of various resins and tungsten powder which are mixed together through special metallurgical technology, which is injection molded. As its special high density of 11.34 g/cm3 min., tungsten polymer has a perfect radiation shielding performance comparable to lead for anti-radiation shielding.

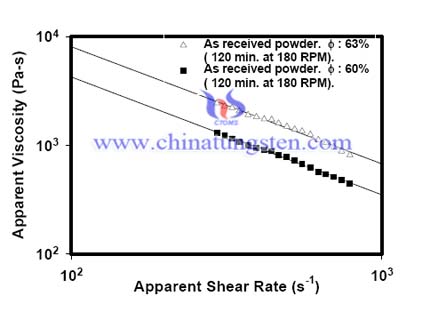

There has been conducted with as-received, agglomerated tungsten powder and rod milled tungsten powder to study the effect of mixing on the homogeneity of tungsten polymer injection molding. An increase in the mixing shear intensity increases the hydrodynamic force and contributes to the agglomerate size reduction. Deagglomeration during mixing improves the packing efficiency of the particles promotes homogeneity. Viscosity is a good indicator of the homogeneity of the feedstock. An increase in the homogeneity of the feedstock is reflected as a decrease in its viscosity. A perfectly homogeneous mixture will have the least viscosity. It is observed that with an increase in the intensity of mixing, the viscosity of the feedstock composed of as-received powder approaches that of the deagglomerated, rod milled powder.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cadmium Borotungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2015 12:07

- Written by xiaoshan

- Hits: 360

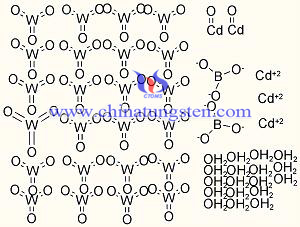

Cadmium borotungstate is a heavy white crystal, soluble in water and the solution is yellow or lilac, besides, it will break down in sunlight. Its chemical formula is Cd5 (BWl2O40) • 18H2O. On the other hand, it can be produced by the thermal reaction of tungsten trioxide, cadmium oxide and borax taken.

As below will introduce using extraction method to produce cadmium borotungstate:

1.Taking 396g Na2WO4H2O dissolved in 300ml water, besides, adding HCl with stirring and heated to 85 ℃, heat preservation for 1-2 hours, PH is maintained at about 3. Then added 18.2g H3BO3 maintained at 85 ℃ for 30 minutes, then add the acid to adjusted PH value to 2, maintained at 85℃ 3-4 hours, cooled and filtered. The filtrate contains 12-boron sodium tungstate.

2. The solution was concentrated placed in a separatory funnel and extracted by ether. At the same time, adding 2-3 volumes of 33% H2SO4 for three times, oscillating for 5 minute to layered, obtained third-phase of heavy oil shaped and then separated the bottom of the third phase. Adding a small amount of water to remove Et2O obtain tungstoboric acid.

3. Adding excess CdO to the tungstoboric acid solution, and then filtered to give claybank solution after concentrated, cooling and crystallized to give an off-white cadmium borotungstate.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com