Tungsten Concentrate Beneficiation – Dry High Intensity Magnetic Separator

- Details

- Category: Tungsten Information

- Published on Monday, 03 July 2017 17:38

Tungsten concentrate is mild magnetic mineral, under certain grinding, it can adjust magnetic intensity or change selection medium to absorb tungsten concentrate on the magnetic medium to realize separation with mineral vein.

So no matter it is tungsten concentrate selection or tungsten slime recovery, magnetic machine can be used to purify to concentrate tungsten concentrate grain, simplify the subsequent processes and save tungsten concentrate beneficiation cost.

High intensity magnetic separator can be divided into dry type and wet type. Although wet type is more widely used, dry high intensity magnetic separator can adapt to drought and water shortage area and has advantages in beneficiate medium and coarse grain minerals.

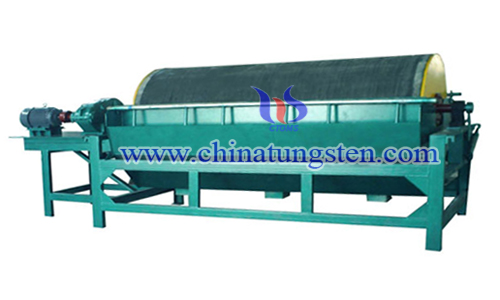

Dry high intensity magnetic separator is mainly used in rougher selection of mild magnetic mineral. Dry high intensity magnetic separator includes roll type high intensity magnetic separator and drum magnetic separator. Magnetic systems are made of high quality ferrite materials or rare earth magnets.

At present, many domestic tungsten mines has abundant water in the southern mountains, so the application of wet magnetic separator is wider. But in the long run, dry high intensity magnetic separator should have a greater market. After all, water is a valuable resource. Not only has a connection with the cost of production, but also affect the lives of residents living in the water side. At present, the dry-type magnetic separator technology has leaps and bounds, in most applications it has better efficiency than wet strong magnetic separator. So it should have a greater application space in the future.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com