The Diffusion of Rare Earth during Tungsten Electrode Arcing

- Details

- Category: Tungsten Information

- Published on Friday, 08 July 2016 17:38

Rare earth can effectively reduce the work function of the electrode surface, lowering the operating temperature of the electrode, which not only can promote electron emission, but also can improve welding performance. Therefore, the largest role of rare earth tungsten electrode is to reduce the surface fuction work to facilitate electron emission, but there are different a lot of different interpretations on electrode emission mechanism. For thorium tungsten electrode, in the arcing process thorium oxide is reduced to elemental thorium, so that the surface of the electrode is covered with a layer of thorium atoms. Besides, the thorium atoms have lower work function, thus the work function of the electrode surface is also lower, which can promote the emission of electrons. But after thermodynamic calculations found that the rare earth tungsten electrode has different emission mechanism with thorium tungsten electrode. In the arcing process, rare earth will not be restored, so that the atomic layer emission mechanism can not explain the diffusion behavior of rare earth in rare earth tungsten electrode.

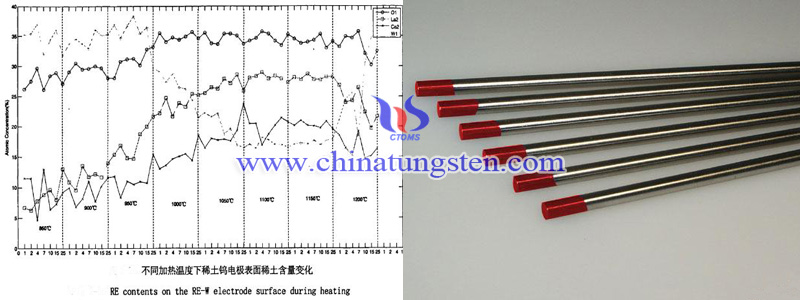

Through high-temperature simulation to study rare earth diffusion behavior. From the test pattern can be seen at 850 ℃, the content of Ce in the tungsten matrix has far more than its theoretical content. This shows that before heating, Ce has spread to the electrode surface, as the temperature rises, the content slowly increases. At 1100℃ the content can up to the maximum value. However, with temperature increasing, the evaporation rate is greater than the surface diffusion rate, so the content began to decrease.

La began to diffuse at 850 ℃. At 1050 ℃, the surface evaporation rate and the diffusion rate can achieve a balance and the La content reached maximum value 25%. When the temperature rises to 1200 ℃, La evaporation rate is higher than the surface diffusion rate and the content began to decrease.

In the rare earth tungsten electrodes, the mainly content change is La, Ce and O, caused by the change. For O, at 850 ℃ -1200 ℃, O is slowly to increase in electrode surface, reached the highest value at 1000 ℃.

Observed electrode arcing morphology change found the electrode tip has high temperature, which can promote rare earth diffuse to the surface. Ce is the first one began to migrate and the fastest. Therefore, during arcing, Ce first began to spread and formed active layer on the surface to facilitate electron emission, promoting arcing success. The diffusion of La is late and the role of it is stable arcing. The main role of O is in the early arcing. A portion O for forming a surfactant layer, the other can react with the tungsten to form gaseous oxides which may volatilize or deposit to the tip of the electrode, the projection formed, and it is conducive to high-frequency arc and stable arc.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com