Nano Tungsten Carbide Developments

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 May 2016 17:02

Generally, tungsten carbide is a kind of super-hard composite material consists of refractory metal carbide (e.g., WC, TiC), and the binder by transition metals or alloys (such as Fe, Co, Ni). It has high hardness, high strength, high melting point, excellent thermal hardness and wear resistance and corrosion resistance and other advantages. In the early 1920s, germen first adapted PM (Powder Metallurgy) to fabricate WC tungsten carbide, which put forward tungsten carbide widely used in aerospace, machinery processing, metallurgy, oil drilling, mining tools, electronic communications, construction, military and other fields.

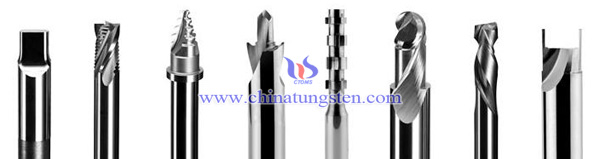

Originally, tungsten carbide mainly used in drawing die and some wear parts manufacturing. And due to the technologies, process and performance improvements, it gradually plays an important role in metal cutting industries. With the further study, the researchers found that the smaller size of WC in granularity, the shorter mean free path of the binder Co, which has a dramatical increase in the hardness and strength of the alloys. Especially when the WC grain size reduces to about 100 nm, there will be a obvious breakthrough in the mechanical properties.

Today, in some emerging industries as well as some areas of difficult to machine materials fields, such as air super-alloy materials processing, electronics industry, using a wide range of printed circuit board (PCB) drilling, composite sheet metal processing, glass-fiber reinforced structural thermoplastic material, dot matrix printer head, the precision cutting of glass, etc., all need to be completed by nano tungsten carbide cutting tools with higher hardness and better strength. However, in the process of tungsten carbide densification, the growth of grains is an inevitable phenomenon. So in order to obtain nano tungsten carbide, we should synthesize finer powder in advance.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com