Tungsten Carbide Ball High Precision Grinding Methods (1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 February 2016 16:49

Due to it has high hardness, high density and high strength, tungsten carbide ball plays an significant role in some oilfield or offshore drilling, which takes place of steel ball and ceramic ball gradually. The conventional grinding process itself due to mechanical constraints as well as some human factors can not exclude the influence can not be guaranteed tungsten carbide blank ball consistency and performance stability. Therefore, many related researchers has studied on tungsten carbide ball high precision grinding methods, which mainly includes eccentric V-slot grinding, angle of rotation controlling and double rotation grinding.

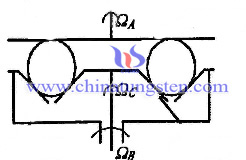

Firstly, since grinding angle active control is an idea of some of the relevant scholars from abroad first proposed, which is also known as three sets of coaxial grinding method. It is based on conventional V-slot grinding method, V-slot portion of the lower plate has been separated, so that the entire body is composed of three independently rotatable grinding disc composition, and then to adjust the ball from the corner of the blank by controlling the speed change three of grinding tray, the schematic given as follow:

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com