Effect of Powder Property on Tungsten Copper Electrode Density

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 January 2016 17:17

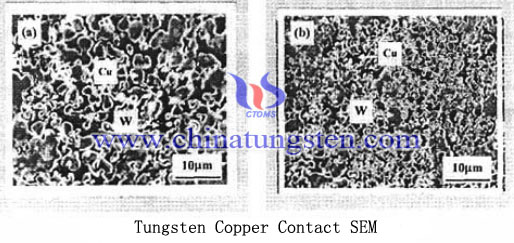

The smaller the particle size, the greater its surface area can be sintered density, the greater the driving force, and therefore tungsten, copper particles smaller particle size will make tungsten copper alloy electrode denser, and particle size on the material the microstructure also has a certain influence. Tungsten copper contact SEM image as follow:

Figure (a) above is the microstructure of our self-developed W-Cu electrode copper tungsten contact material, and (b) of the microstructure of foreign tungsten copper W-Cu electrode contact material. There is an obvious difference between them. W particles of tungsten copper electrode contacts abroad dispersed evenly, distributed copper Cu substrate gap in the tungsten W skeleton and both of two metals has good wettability; the W particles of tungsten copper electrode contact domestic are more coarse and distributed unevenly. Therefore, the difference of contact material is related to the granularity of tungsten powder and the granularity of tungsten powder has a remarkable influence on the properties of tungsten copper alloy. The related experiment shows that with the decreasing granularity of tungsten powder, the corrosion rate decreases. If the granularity of tungsten powder is too fine, the particles will aggregate to block out the path of tungsten skeleton, which leads to insufficient infiltration, macro-segregation, porosity, Cu-concentration and other defects.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com