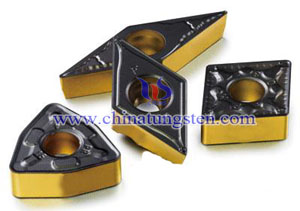

Coated Cemented Carbide Types——Multi-layer Coating

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 January 2016 17:15

Since coated cemented carbide developed, coating types were diverse, such as single-layer coating, multi-element composite coating, gradient coating, nano coating, super-hard coating and soft coating.

2. Multi-layer Coating

With the development of coated cemented carbide technology, single-layer coating has a transition to multi-layer coating with excellent properties. Multi-layer coating combines with excellent properties and applicability of different materials, which improves the comprehensive properties of the matrix further. At present, the major double-layer coating has titanium carbide/titanium nitride (TiC/TiN), titanium carbide/aluminum oxide (TiC/Al2O3), titanium carbide nitride/aluminum oxide (Ti(C,N)/Al2O3), titanium nitride/cubic boron nitride (TiN/CBN) and so on. TiC/Al2O3 coating is the earliest and the most widely used, which compared with single-layer TiC has higher hardness and better wear resistance, and the TiN has excellent chemical stability (in case of the diffusion) and crater wear resistance. In addition, TiC has closer coefficient of thermal expansion to the matrix than TiN, which usually used in the basic coat and has better binding force with the matrix. Its internal residual stress is small so that it can effectively resist the cracks expanding. Generally, TiC/TiN coated cemented carbide cutting tools is more suitable for machining, semi-finishing and precise cutting; TiC/Al2O3 coated cemented carbide has higher heat hardness and toughness, which is suitable for high-speed cutting or high-load cutting.

The common coating with three layers is TiC / Ti (C, N) / TiN, by austenitic stainless steel turning experiments some researchers find that due to TiN coating has small friction factor and has small cutting force, which is suitable for semi-finishing and precise cutting. Besides, TiN/TiC/TiN composite coating has better wear resistance, binding force with the matrix, thermal shock resistance than single-layer coating, which can be widely used in alloy steel, structural steel and high-speed milling. In a word, the more coating layer, the more advantages in high-speed cutting and milling, and with the development of technology, the coating layer become thinner. Multi-layer coating on the physical structure, mechanical properties and chemical properties of the material aspects of carbide cutting tools gives more excellent transition, is the prototype of functionally gradient materials.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com