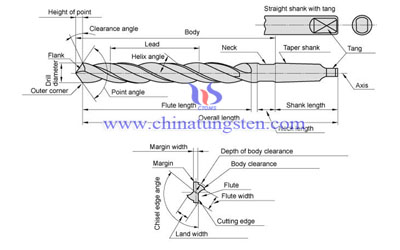

Tungsten Carbide Drill Geometry

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 May 2015 14:47

The most appropriate tungsten carbide drill geometry to apply for drilling depends on the characteristics of the material being drilled. Generally tungsten carbide drill geometry includes, rate of twist , point angle, lip angle and the overall length of the drill.

The drill’s rate of twist indicates the chip removal rate. For the high feed rate usage during the low spindle speeds, if a large volume of swarf removal is asked, a high twist rate drill is recommended. On the contrary, a low twist rate drill is used in high spindle speeds and where the material has a tendency to gall on the bit or otherwise clog the hole, such as aluminum or copper.

Point angle is determined by the working pieces’ material. A lager point angle is suitable for harder material whereas the softer material matches a sharper angle.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com