Tungsten Carbide Drill Geometry(1)

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 May 2015 14:47

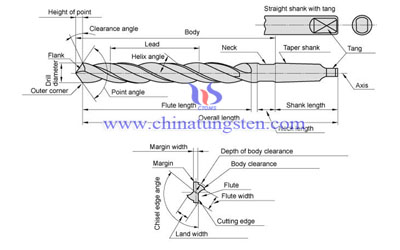

The most appropriate tungsten carbide drill geometry to apply for drilling depends on the characteristics of the material being drilled. Generally tungsten carbide drill geometry includes, rate of twist , point angle, lip angle and the overall length of the drill.

Lip angle controls the support volume offered to the cutting edge. When under the same amount of point pressure, if the drill with a smaller lip angle, it shows the larger the lip angle, the more aggressively the cutting will be. In addition the accurate lip clearance is controlled by the point angle.

Drill’s overall length controls the length of a hole can be made, the drill’s stiffness and the final hole accuracy.Specially straight shanks are adopted by most drill applications , and drill with tapered shanks are proper for the heavy duty drilling.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com