Molybdenum Boat

- Details

- Category: Tungsten Information

- Published on Thursday, 29 May 2025 16:52

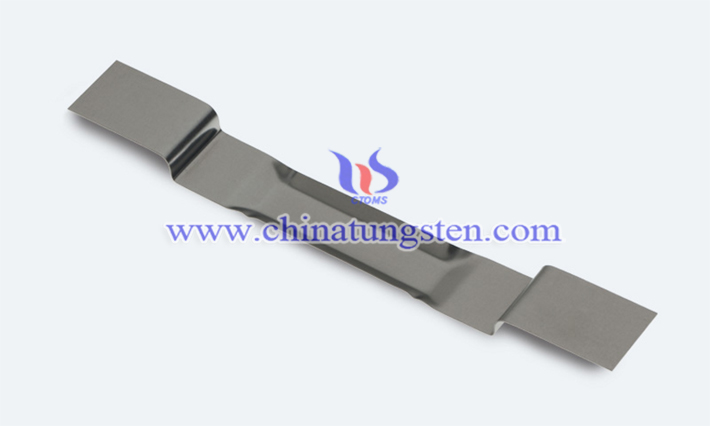

As a typical product of the transition metal molybdenum, a molybdenum boat, also known as an evaporation molybdenum boat or coating molybdenum boat, is made from molybdenum sheets or molybdenum-based alloys through welding or high-temperature stamping. It serves as a critical sintering carrier for molybdenum powder and other metal powders, with its English name being "molybdenum boat".

Physicochemical Properties

Molybdenum boat generally exhibits high density, high melting point, high strength, low thermal expansion coefficient, high-temperature resistance, corrosion resistance, excellent creep resistance, ductility, and good electrical and thermal conductivity. Note that the specific physicochemical properties and applications of Molybdenum boat vary depending on the material. For example:

Pure molybdenum boats (Note: Here, "boats" refers to different types or instances, which can be retained if the context implies multiple examples; if strictly singular, adjust to "a pure molybdenum boat") can withstand temperatures around 1,100°C and are suitable for melting rare earth materials and sintering tungsten oxide.

Molybdenum-lanthanum alloy boat and a TZM (molybdenum-zirconium-titanium) alloy boat can endure temperatures up to 1,900°C, making them ideal for high-temperature environments.

Classification

By Shape: Molybdenum boat can be circular, rectangular, square, or trapezoidal.

By Processing Method: It can be categorized as a stamped boat, folded boat, welded boat, or riveted boat.

By Material: It includes a pure molybdenum boat, molybdenum-lanthanum boat, molybdenum-zirconium-titanium boat, molybdenum-rhenium boat, and tungsten-molybdenum boat.

Structure

A high-temperature-resistant molybdenum boat typically features a rectangular boat body with a semi-elliptical sintering liner and wave-shaped heat dissipation strips around the edges. Weight-reduction holes are positioned beneath the wave-shaped strips, and the boat body is equipped with a split lid, which includes coating holes and injection holes. The advantages of this design are:

The semi-elliptical sintering liner prevents deformation under prolonged use.

The wave-shaped heat dissipation strips and weight-reduction holes reduce the boat's weight and enhance heat dissipation speed.

Applications

Molybdenum boat is primarily used in coating technology, the electronics industry, and power engineering, serving as a container for capacitor sintering, vacuum thermal evaporation, and nuclear fuel sintering.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129595/5129696 Email:sales@chinatungsten.com |

| Tungsten News & Prices: Chinatungsten Online news.chinatungsten.com | Molybdenum News & Molybdenum Price: news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com