Molybdenum Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 29 May 2025 16:50

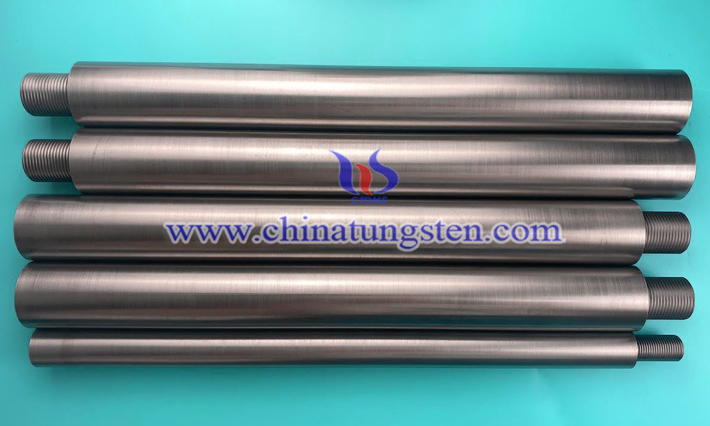

As a key component made from the transition metal molybdenum (with purity exceeding 99.95%), a molybdenum electrode—known as "molybdenum electrode" in English—shares physicochemical properties highly similar to pure molybdenum. Its typical diameter ranges from 20 mm to 152.4 mm, and its length can extend up to 1,500 mm. Notably, a molybdenum electrode differs significantly from a tungsten electrode in both shape and application.

Physicochemical Properties

Molybdenum electrode appears as a silver-gray solid with a metallic luster. It features a high specific gravity (10.23 g/cm³, approximately half that of tungsten), a high melting point (2,622°C), remarkable hardness, high thermal conductivity, a low thermal expansion coefficient, and excellent heat resistance, corrosion resistance, and chemical stability.

Classification

By Shape: Molybdenum electrode can be categorized into electrode rods, plates, poles, and threaded electrodes, each serving distinct purposes. For example, an electrode rod is mainly used in electric-melting glass furnaces, while an electrode plate is applied in heating equipment for various glass fiber furnaces and liquid flow hole panels.

By Surface Condition: It can be pided into sintered molybdenum electrodes (with a gray metallic luster), forged molybdenum electrodes (with a black surface), machined molybdenum electrodes (with a flat but rough surface), alkali-washed molybdenum electrodes (with a smoother surface), ground molybdenum electrodes (with a smooth surface), and polished molybdenum electrodes (with a bright and glossy surface).

Production Process

The preparation of a high-purity molybdenum electrode involves the following steps: molybdenum powder is first pressed into a molybdenum billet, which undergoes pre-sintering in a resistance sintering furnace, followed by two-stage sintering in a medium-frequency induction furnace. This process yields a product with carbon and oxygen content below 10 ppm.

Applications

Molybdenum electrode is used in industries such as glass wool, insulation wool, optical glass, daily-use glass, rare earth industry, glass fiber, refractory fiber, glass liquid, and water-cooled sleeves. Specifically, in the production of glass wool or insulation wool, Molybdenum electrode primarily serves as a heating component in industrial furnaces.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129595/5129696 Email:sales@chinatungsten.com |

| Tungsten News & Prices: Chinatungsten Online news.chinatungsten.com | Molybdenum News & Molybdenum Price: news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com