100 Years of Doped Tungsten WireⅠ- Early Attempts at Metallurgy

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 July 2022 18:47

From a historical perspective, William D. Coolidge's development PM process and tool "for making tungsten ductile" in 1909 marked the beginning of the use of tungsten filaments in the lighting industry. William D. Coolidge's development of the PM process and tools to "make tungsten ductile" in 1909 marked a breakthrough in the use of tungsten filaments in the lighting industry and began the modern industrial era of Powder Metallurgy.

Before introducing the Coolidge process, some important technological developments (Just & Hanaman procedure, Kuzel process, Pintsch method) and the corresponding impact on today's modern technologies and materials (Sol-Gel, CVD, MIM, ODS alloys, W-RE welded electrodes) will be briefly described. This article will correct some of the recurring misconceptions about the Coolidge process, especially about the doping process. Then, we will mention some discoveries and inventions derived from this period (tungsten heavy metals, gradient materials, cemented carbides). In addition, the scientific importance of potassium bubbles as the strongest pinning points to prevent dislocations and grain boundary shifts at ultra-high temperatures will be described. Because of the characteristic dimensions involved, it is important to understand the microstructural characteristics of ultrafine wires and the corresponding fabrication of diamond dies in the context of wire deformation, which also represents the leading technology in nanotechnology and micromachining today.

Introduction

In 1879, T. A. Edison and J. W. Swan invented the electric lamp with a carbon filament, heralding a new era of electrical lighting, and the history of tungsten filament processing is inseparable from the development of this branch of industry.

In the initial stages of the new era of electrical lighting, all early lamps had small gaps due to technical limitations, in which the carbon filaments were low light output and had a short life span, blackened bulb walls as well as a pronounced brittleness. As a result, the search for better incandescent lamp materials began, and with it came the "gas mantle lamp" invented by Carl Auer von Welsbach in 1883 and the "Nernst lamp" in 1898. To commemorate the 150th anniversary of the birth of Carl Ohr von Welsbach (1858-1929), the Austrian Mint issued a bimetallic silver/niobium coin called "Fascination Light" in 2008. The value side of the coin features a nostalgic gaslight lighter in front of the Vienna City Hall, while the reverse side features a bust of Karl Auer von Welsbach and a series of light sources (Figure 1). Today, there are many historic gas lamps are burning around the world, for example, more than 40,000 in the old quarter of Berlin, including a nostalgic gas lamp museum in the so-called "Tiergarten" district, as well as in other German towns, as well as in London and Boston (Lighthouse Hill), Prague (Charles Bridge) and the birthplace of Welsbach in Althofen (Austria) (Figure 2).

Fig. 1. Auer von Welsbach coin, Austria, 2008

From a present-day perspective, further advances, particularly the introduction of tungsten as a filament material, have been modern interdisciplinary developments involving a combination of scientific insight, growing material understanding and process technology. Knowledge, intuition and, most importantly, commercial requirements, with earlier work occurring in the first decade of the 20th century. Since the early of last century, tungsten has been increasingly used in light bulbs, especially in home lighting.

This process is now commonly used by companies around the world to manufacture ductile tungsten wires to meet various needs, and is commonly referred to as the Coolidge process - in honor of its developer, William D. Coolidge. In addition to the importance of tungsten technology to the light industry, the different processing steps have formed the basis for the advances and successes of modern powder metallurgy in many other materials today. It was largely Coolidge's stay in Leipzig and his meeting with Roentgen in 1899 that led him to develop an improved version of the X-ray tube, the so-called "Coolidge tube", in 1913.

Fig. 2. Auer gas mantle lamps, Berlin (Tiergarten)

This review will focus on the historical and scientific aspects of tungsten filament processing. The first part of the article discusses the early metallurgical experiments to make tungsten filaments for the lighting industry and their impact on today's modern materials and technologies. In the second part, we describe the modern scientific background of the Coolidge process and nanoscale potassium bulbs. The third part unfolds the new challenges of tungsten materials science and provides an outlook on the future of tungsten filaments in light of new technological and political developments in light sources.

Early attempts at metallurgy

Following the discovery of the Auer gas bowl lamp and the Nernst lamp (using ceramics as incandescent elements), the so-called "squirted" osmium lamp followed. The first metal filament lamp was developed by C. Auer v. Welsbach in 1898. A few years later, W. von Bolton and O. Feuerlein introduced a lamp with drawn tantalum filaments in 1902. It is worth noting that the wire drawing technology of the time was already capable of stretching the diameter of a high melting point metal to around 50 μm. The tantalum lamp was the first wire lamp to enter a truly commercial phase, largely replacing the German osmium lamp. That was when General Electric (GE) acquired the exclusive rights to produce tantalum lamps in the United States. However, the high evaporation rate of early osmium filaments and the brittleness of tantalum filaments when using alternating current led to their strong disadvantages. Interestingly, in 1905, William Coolidge was the first person to work at GE. Coolidge conducted an in-depth study of the brittleness of imported German tantalum wire during his first year at GE. Despite this, the famous steamship Titanic was still outfitted entirely with tantalum filament bulbs until 1912.

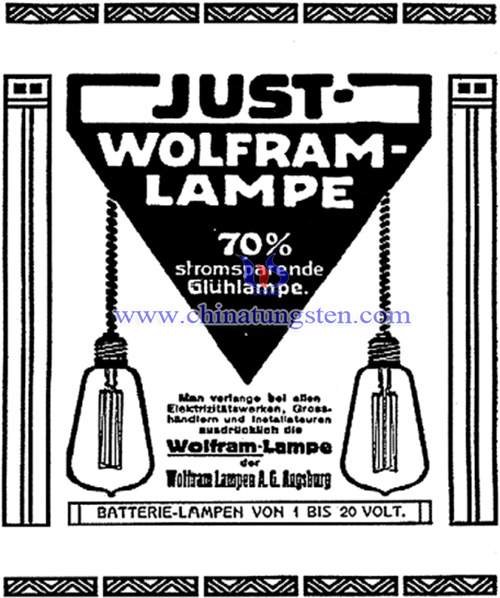

However, in 1903, the first tungsten filament lamp by A. Just and F. Hanaman marked a new era in modern lighting, increasing the efficiency of carbon lamps from about 3.2 lumens per watt (lm/W) to about 7.9 lm/W. At the same time, the efficacy of the first metallic filaments (osmium and tantalum) (about 6.3 lm/W) was also greatly surpassed. The reason that tungsten was not studied in the early days may be that information on its melting point was incorrectly recorded at that time, especially the description of tungsten appeared to be inherently brittle. As early as 1912, M. Pirani and A. R. Meyer of Siemens and the Halske Metal Laboratory (a few years later part of the newly formed OSRAM research group in Berlin) had already determined the melting point of tungsten to be 2965°C (about 450°C below the true value of 3420°C).

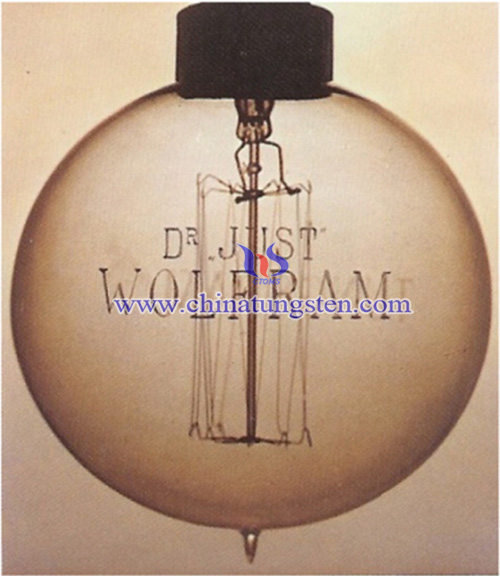

The first patents of A. Just and F. Hanaman probably date back to the early investigations of A. de Lodyguine and the osmium filaments of Auer von Welsbachs. They heated carbon filaments in a mixture of tungsten oxychloride and H2, resulting in deposits of tungsten on the carbon surface and the formation of brittle tungsten carbide in the core (Figure 3). The transformation of tungsten carbide to tungsten at high combustion temperatures in the lamp and the annealing of the filament in moist H2 resulted in the formation of a brittle pure tungsten tube.

The next milestone was a new patent in 1904 by A. Just and F. Hanaman. Following the recognition that carbon increases the brittleness of tungsten, a tungsten compound was mixed with a carbon-free binder, avoiding the earlier mixture of sugar and glue, to create a binder. The binder is then extruded through a fine diamond die, wound into wire loops, cut into "hairpins" and then heated to red in a suitable gas mixture to remove the binder. Each "hairpin" with a straight section is then mounted in a clip and heated by an electric current in a hydrogen background. At very high temperatures, the fine tungsten particles are sintered together to form the skeleton of a solid tungsten filament (Figure 4).

Fig. 3. First tungsten coated carbon lamp, 1905

These filaments are elastic but rather brittle, but they can be processed into hairpin or loop when heat. The method is similar to Auer von Welsbach's process of squirted osmium filaments. However, this patent was purchased by the Auer-Gesellschaft (DGA) of Germany in 1904. In Hungary, under Just and Hanaman's patent, tungsten lamps were also produced at Egger in Budapest, later TUNGSRAM, and in 1906, under Just and Hanaman's patent, the new tungsten lamp was presented to a delegation from GE in New York in Berlin. Shortly thereafter, DGA and GE signed a patent license agreement for the tungsten lamp and a technology exchange agreement for the extruded ("squirted") wires. The agreement gave GE exclusive patent rights in the United States.

From about 1905-1911, most tungsten filaments were produced using this method, although many different alternatives were established in the research laboratories of lighting companies.

In the United States, William. Coolidge introduced a mercury-mixed tungsten filament consisting of mercury, cadmium and bismuth (as a binder for tungsten powder) in 1906. The mixture was also ejected through a die as usual, after which the binder was removed by applying high temperatures. The bonding of the tungsten particles is carried out in the filament under passing current.

However, this filament was still too brittle. Coolidge then discovered that less brittle filaments made by his amalgam process could be pressed between heated blocks of steel or by rolling mills with heated steel rolls.

Fig. 4. Squirted tungsten lamp, 1910

This can already be considered as the basis for the later successful thermomechanical treatment of sintered tungsten ingots. After three years of intensive research and development, Coolidge and his colleagues finally succeeded in producing tungsten wires with good ductility and amalgamation that could be drawn through diamond dies down to 0.249 mm.

It is interesting to note that between 1906 and 1910, a patent license agreement was also reached between Auer and GE, which led the Auer team to support the installation of the first tungsten production facilities in Schenectady, New York, based on Just and Hanaman patents. In appreciation for their help in setting up the U.S. tungsten lamp plant, GE colleagues gave DGA access to their swaging and drawing processes and related Coolidge patents a few years later. The procedure was repeated in the late 1970s when experts from German Osram GmbH supported the installation and introduction of a Kocks mill operation for tungsten deformation at GE in Cleveland, Ohio.

At the beginning of the last century, there were many technological developments that, although they had little success in the lighting industry, influenced some of the major advances in materials technology that followed.

- 1905: H. Kuzel: Squirtin process of tungsten powder pastes with sugar and gum as binder and decarburization in H2/H2O gas mixture.

- 1905: H. Kuzel: Tungsten colloid process without binder.

- 1906: Siemens and Halske: Filling of copper tubes with fine tungsten powder, heating as well as deformation by rolling or drawing.

- 1907: AEG: Development of tungsten-nickel (2-4%) for drawing tungsten wires, including evaporation of nickel annealed in a vacuum.

- 1907: J. Pintsch: Single crystal process developed from spray extruded thoriated tungsten by zone/gradient annealing.

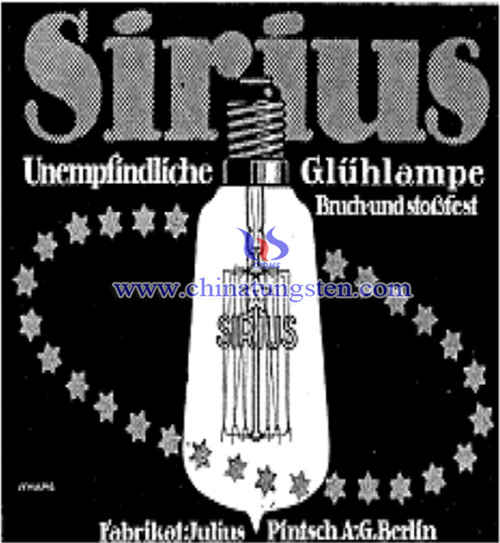

Figures 4 through 5 depict some early examples of lamps where all filaments were straight due to the brittle nature of tungsten. As an exotic example, Figure 6 shows a picture of a century-old carbon bulb from the Livermore, CA Fire Department, where the filament has undergone significant deformation due to creep processes.

Fig. 5. Sirius colloid lamp, 1910

In addition, Figure 7 shows the "squirting process" and the "gradient annealing" principle according to J. Pintsch. After squirting, the thoriated tungsten wires are treated with a temperature gradient of about 2200°C to induce the growth of long single crystal fibers.

C. Auer von Welsbach, A. Just and F. Hanaman's “squirting” technology, H. Kuzel's "colloid process", and Wilhelm Coolidge's "amalgam process" together formed the basis of modern MIM (metal injection molding) technology. Coolidge's "amalgam process" formed the basis of modern MIM (Metal Injection Moulding) technology. All of these technologies use the squirting process, whose main drawback is the limited ductility and the inability to further process the filament and the lamp. In addition, Siemens and Halske's patents can be considered as the forerunners of today's modern deformation processes for superconducting wires. Tungsten-nickel pseudo-alloy technology developed by AEG in 1935 was the precursor to the introduction of heavy metal alloys into production. The Pintsch process formed the basis for the later single crystal technology and today's gradient annealing (see Table 1).

In addition, the Pintsch process and the development of the Pintsch single-crystal wire based on thorium-plated tungsten were the main reasons for the invalidation of the William Coolidge patent in 1927. Coolidge's patent was invalidated in 1927.

(Credit: P. Schade “100years of doped tungsten wire”, International Journal of Refractory Metals and Hard Materials, Volume 28, Issue 6, 2010, Pages 648-660, ISSN 0263-4368)

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com