The Advantages of Tungsten Alloy Applied in Medical Shielding

- Details

- Category: Tungsten Information

- Published on Thursday, 10 February 2022 22:58

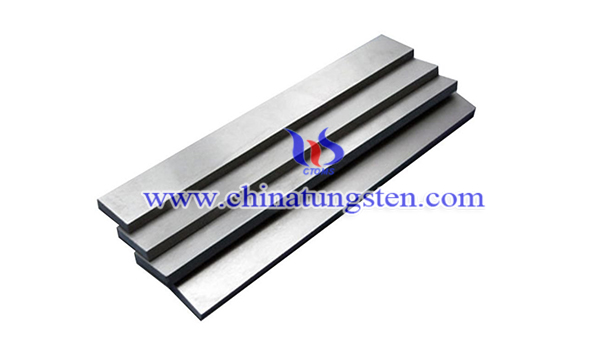

Tungsten alloy has the advantages of high density, machinability, good corrosion resistance, and high radiation absorption capacity, and high strength. It is widely used in the fields of aerospace and automotive industries and radiation shielding.

Tungsten alloys are best suited for applications where there is a requirement for a large weight concentrated in the minimum possible space. Tungsten has a density that is approximately 1.7 times higher than the traditional shielding material: lead. The radiation shielding property of a material is closely related to the density of the material. Higher density means better radiation absorption and radiation shielding capabilities.

Thus, it provides a higher degree of shielding. This is a viable option for applications where lead is not feasible, including reducing size, and maximizing weight in large or small cavities for radiation shielding. It is strong and highly customizable into precision components. The high specific gravity tungsten alloy shield has better shielding properties to γ-rays so that the volume of the shield can be reduced. Compared with lead, tungsten alloy shields of the same volume with high specific gravity have better radiation shielding properties. In addition, since tungsten alloys are non-toxic and pollution-free, they are more environmentally friendly than lead and depleted uranium. To prevent exposure, lead may need to be encapsulated or coated.

In conclusion, tungsten is the preferred choice for medical and industrial settings that require radiation shielding since it uses less material than lead to provide the same level of absorption. An excellent shielding material, tungsten guarantees minimum radiation exposure and ensures ALARA (as low as reasonably achievable) goals in the workplace. Machinability, radiographic density, strength, low toxicity, and heat resistance allow for superior design adaptability vs. other shielding materials. Because tungsten alloy features high density (density 60% higher than lead), machinability, good corrosion resistance, and high radiation absorption capacity (better than lead and steel), high strength, tungsten alloy is the best raw material for shielding parts. Tungsten alloy shields still have the same radiation shielding capabilities as lead, although the volume and thickness of tungsten alloy shields are reduced.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com