Smart Glass Electrochromic Device Prepared Based on Tungsten Oxide Films

- Details

- Category: Tungsten Information

- Published on Sunday, 05 September 2021 18:06

In the past few decades, electrochromic devices have received great attention from researchers in related fields in the materials industry. Electrochromism is a reversible change in optical properties (such as absorbance and transmittance) of a material under low electric fields. Electrochromic devices have a wide range of applications, including reflective displays, smart windows, information displays, and electrochromic paper.

Tungsten trioxide (WO3) has been considered an excellent EC material. However, its drawbacks such as poor stability and slow switching time have limited its large-scale applications. Although amorphous WO3 thin films have demonstrated good optical performance and high coloration efficiency they still suffer from poor electrochromic repeatability, longer response time and stability.

Smart glass electrochromic device has been prepared based on tungsten oxide films, the tungsten trioxide films exhibited good optical modulation and high electrochromic performance. The synthesis of the WO3 films-based electrochromic device is as following steps:

Ammonium tungstate hydrate ((NH4)6W12O39.xH2O, Alfa Aesar) and oxalic acid (C2H2O4, Merck) are used as oxidizer and fuel, respectively. The oxidizer-to-fuel ratio (O/F) is maintained at 1. According to the reaction given in the equation. (1) Weigh 6.08 g of hydrated ammonium tungsten oxide and 2.27 g of oxalic acid. The two chemicals were dissolved in 15ml of distilled water. Then, the two solutions were mixed and magnetically stirred for 15 minutes. Use a heating mantle to initiate a combustion reaction at 300°C. Within a few seconds, the reaction was completed, and the synthesized powder was washed several times with ethanol. After filtration, the powder was dried at 80°C overnight. Due to the explosive nature of the reaction, the amount of powder obtained is less than the theoretical value.

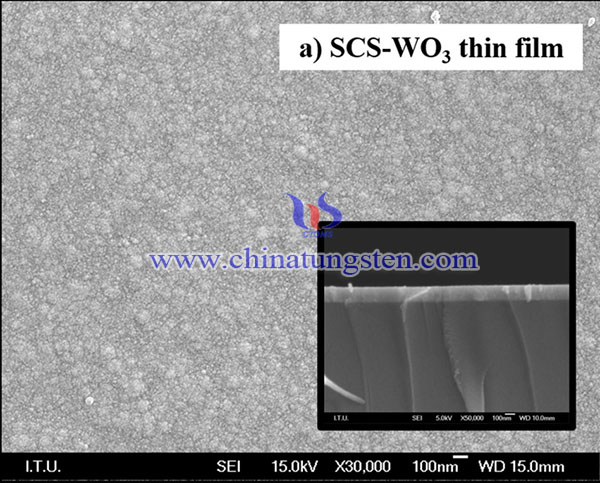

For comparison, the following steps were performed on commercial tungsten oxide powder (purity 99.8%, Alfa Aesar) and synthesized WO3 powder to obtain a thin film under the same conditions. SCS-WO3 and C-WO3 powders were prepared with particles with a diameter of 1 cm and a thickness of 0.14 cm, respectively, and then sintered at 850°C for 8 hours. The cleaning procedures for ITO (Indium Tin Oxide) and Corning glass substrates are ultrasonically cleaned in acetone, deionized water, alcohol, and deionized water. Each step includes 10 minutes. Two kinds of particles prepared by electron beam evaporation in a copper boat are deposited on the substrate of the WO3-x thin film. During the evaporation process, the vacuum degree is about 8.2×10-6 Torr. During the coating process, the substrate is kept at room temperature, and the deposition rate is 2Å/s.

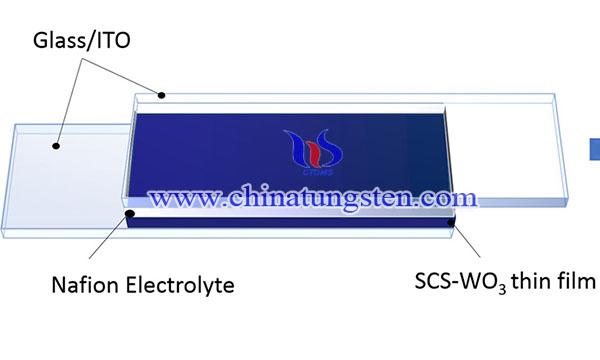

In summary, smart glass electrochromic device has been prepared based on tungsten oxide films, the tungsten trioxide films exhibited good optical modulation and high electrochromic performance. It is found that the SCS-WO3 thin film evaporated by electron beam exhibits an amorphous, homogeneous and uniform structure, and has high-efficiency electrochromic properties (ΔT=68% at 550nm and CE=60cm2/C) and C-WO3 thin film (ΔT= 58% at 550nm and CE=44cm2/C) has high coloring efficiency and optical transmittance modulation. In addition, the two samples also showed rapid coloring and bleaching speeds during the ±1V switching period. Then, Nafion electrolyte is used to manufacture an all-solid ECD based on SCS-WO3 (ΔT=63% at 550nm and CE=97cm2/C). In the future, the innovative SCS-WO3 film can be directly and widely used in energy-saving smart display applications.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com