WO3-Based Composite Nanofibers with High Visible Light Photocatalytic Activity

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 August 2021 22:33

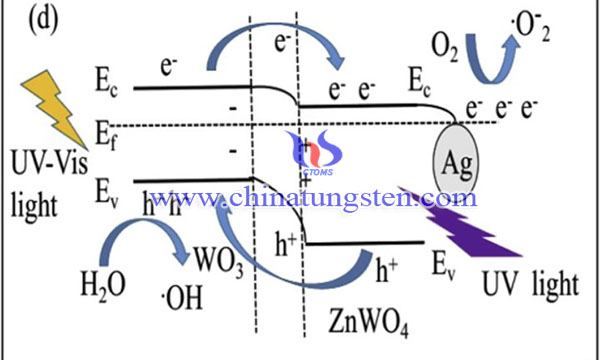

Photocatalysis is a great technology to treat wastewater with environmental protection, more straightforward operation, high mineralization rate, and strong oxidation ability to efficiently remove the low concentration of organic pollutants in water.Tungsten trioxide (WO3) is a promising candidate for photocatalyst owing to its narrow energy gap (2.4–2.8 eV), high oxidation potential (+3.1–3.2 VNHE) of the valence band (VB), which is further meritorious for inducing the performance under visible light. WO3 is a widely studied metal oxide semiconductor for many cutting-edge applications such as photo/electrocatalysis, energy storage, smart window, antibacterial, anticancer agents, and pathogens control. Zinc tungstate (ZnWO4) has a wide band gap (about 3.8–5.7 eV) and possesses matched band structures with WO3. The introduction of ZnWO4 not only significantly promotes electron-hole separation but also broadens the absorption edge of WO3 and increases light absorption. Moreover, the addition of noble metal silver (Ag) can improve visible-light photocatalytic efficiency due to the increase of electron-transfer between semiconductor and noble metal.

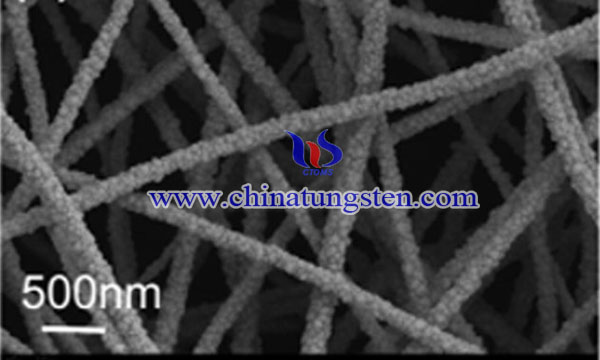

WO3-based composite nanofibers with high visible light photocatalytic activity has been successfully prepared, rate of charge carrier separation has been greatly enhanced. A novel Ag/ZnWO4/WO3 composite nanofibers are successfully fabricated by a facile electrospinning route followed by subsequent annealing treatment. The synthesis and characterization of Ag/ZnWO4/WO3 composite is as below:

In a typical procedure, Ammonium Metatungstate (AMT, 1.3 g) was dissolved in 2 mL deionized water. Subsequently, 3 mL DMF, 0.6 g Polyvinylpyrrolidone (PVP), 0.002 g AgNO3 and 0.1 g ZnNO3 were added into the above mixture in turn under magnetic stirring. After stirring for 24 h at room temperature, the obtained homogeneous precursor solution was transferred into the injector for electrospinning. A voltage of 15 kV and a collection distance of 11 cm were applied for the electrospinning process. Then, the collected samples were annealed in a furnace at 500 °C for 4 h in air with a heating rate of 2 °C/min to obtain Ag/ZnWO4/WO3 composite nanofibers. The fabrication procedure of Ag/WO3 and WO3 nanofibers was like that of Ag/ZnWO4/WO3 composites. In absence of ZnNO3 and AgNO3/ZnNO3 respectively, Ag/WO3 and WO3 nanofibers were obtained, respectively.

Photocatalytic activity test was performed as follows. 0.1 g Ag/ZnWO4/WO3 (or WO3, Ag/WO3) composite nanofibers were added to 250 mL MB (200 mg/L) aqueous solution and the suspension solution was stirred in the dark for 30 min until the adsorption/desorption process reached equilibrium. A 300 W Xe lamp was employed as the UV–visible light source, and it was placed 13 cm away from the solution. In every 15 min, 4 mL of the solution was taken away and the suspension was removed by using centrifugation. Then measuring the maximum absorbance at 664 nm of the MB by the spectrophotometry.

In summary, WO3-based composite nanofibers with high visible light photocatalytic activity has been successfully prepared, rate of charge carrier separation has been greatly enhanced. the distinctive Ag/ZnWO4/WO3 composite nanofibers photocatalyst have been successfully prepared and they show much higher photocatalytic activity than Ag/WO3 and WO3 nanofibers. The as-prepared Ag/ZnWO4/WO3 can increase the efficiency of visible light absorption, promote the rate of charge carrier separation effectively, and as a result, their recombination processes are suppressed. Benefiting from structural and composition advantages, Ag/ZnWO4/WO3 nanofiber is a feasible material for photocatalysis, batteries, filtration, sensor and other applications.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com