WO3 Films as Electrochromic Material for Smart Glass Applications

- Details

- Category: Tungsten Information

- Published on Friday, 27 August 2021 16:07

Electrochromic (EC) materials have received distinguished attention because of their potential applications in smart windows, displays, and antiglare rearview mirrors. More interestingly, the electrochromic smart windows are considered being able to provide indoor comfort and reduce energy consumption in buildings because it could exhibit an ability to regulate the amount of sunlight entering the buildings. To achieve the excellent energy-saving effect, electrochromic smart windows should be able to adjust to near-infrared light along with visible light due to its broad range in sunlight.

Among the several EC materials, tungsten trioxide (WO3) is considered as the most promising one due to its high coloration efficiency, good cyclic stability and low-cost. However, the current EC materials suffer from low performance, low response time and high energy consumption. The literature review shows that nanostructure features play an important role for improving their electrochromic properties. Therefore, many researches focus on designing new nanostructure features of WO3 films using different techniques in order to increase the switching responses, the coloration efficiency, and the cycling stability of the films.

Herein, the tungsten trioxide (WO3) films were prepared on an indium-doped tin oxide (ITO) glass substrates in an atmospheric system at room temperature by the sparking method using external electric fields. WO3 films have been successfully produced as electrochromic material for smart glass applications, monoclinic structure is achieved at annealing temperature of 300 °C. The fabrication process of WO3 electrochromic films is as below:

First, the experiment was started with sparking off tungsten wires (Ø 0.25 mm, purity 99.8%) under high DC voltage of ~3 kV that was discharged from a 24 nF capacitor. The tungsten wires were then placed horizontally with 1 mm spacing (d) in ambient condition at atmospheric pressure. These conditions caused the repetition rate and pulse duration of sparking were approximately 6.2 Hz and 0.16 s, respectively.

The Cu plate (Ø 10 mm, purity 99.0%) was used as an anode and an ITO glass substrate (10 × 10 mm) container as a cathode which were then placed vertically at 1.5 cm spacing (h). A high DC voltage of ~9 kV was applied to the electrodes to produce the external electric fields (Eext) of 6 kV/cm between sparking tips, which correlates to E α V/d. The as-deposited films in this work were synthesized on an ITO glass substrate for 20 min by the sparking method using an external electric field of 6 kV/cm, in order to enhance the uniformity and the deposition rate of films as confirmed by our previous paper. Finally, the films were annealed at different annealing temperatures ranging from 200 to 500 °C for 1 h in atmospheric pressure.

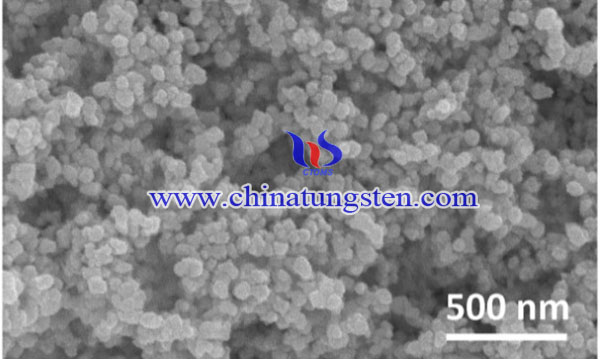

In summary, WO3 films have been successfully produced as electrochromic material for smart glass applications, monoclinic structure is achieved at annealing temperature of 300 °C. The SEM images shows that the nanoparticle's size increases with increasing the annealing temperature. The annealed sample at 300 °C was found to have a large optical modulation of 16.3%, fast switching response of 1.2 s and 2.6 s (for coloration and bleaching state respectively), and high coloration efficiency of 49.6 cm2/C. These results indicate that its morphology provides a high surface area and high coherence of the particles in the film. In addition, the coloration efficiency decreases for the films annealed at temperature higher than 300 °C which is result of the high crystallinity of WO3 films.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com