Nanosized Tungsten Trioxide Prepared Toward Gas Sensing of NO2 and Ethanol

- Details

- Category: Tungsten Information

- Published on Friday, 20 August 2021 01:43

Transitional metal oxides (TMO) such as ZnO, CuO, CdO, TiO2, and NiO had been widely applied in the field of gas sensing. Tungsten trioxide (WO3) is one of the n-type semiconducting TMO materials which possess fantastic properties such as wide band gap, thermal stability and surface-active sites. The WO3 nanomaterials also studied for various applications viz photocatalysts, photoelectrode, photochromism. The WO3 with various morphologies such as cauliflower, thin film, nanosheets and nano-spherical particles have been utilized for gas sensing. Nanosized WO3 is very sensitive toward reducing and oxidizing gas such as ethanol and Nitrogen dioxide (NO2).

Ethanol is a common volatile organic compound (VOC) widely used in many commercial applications, such as drinks, food, and fuel for vehicles. However, drunk driving often causes fatal road accidents. Therefore, Ethanol detection is of high interest, and WO3 based sensors are promising materials. Moreover, NO2 is a gas that can cause acute respiratory illness in children when exposed at a concentration greater than 53 ppb. The excellent response toward NOx gases makes WO3 based sensors relevant for commercial applications.

Thus, RF-sputtering technique had been applied in WO3 nanorod thin-film gas sensors prepared with different controlled thicknesses on SiO2/Si substrates for C2H5OH and NO2 sensing applications. Nanosized tungsten trioxide has been fabricated targeting gas sensing of NO2 and ethanol, the produced sensors possess good baseline stability, good repeatability, and fast response. The synthesis process of is as following steps:

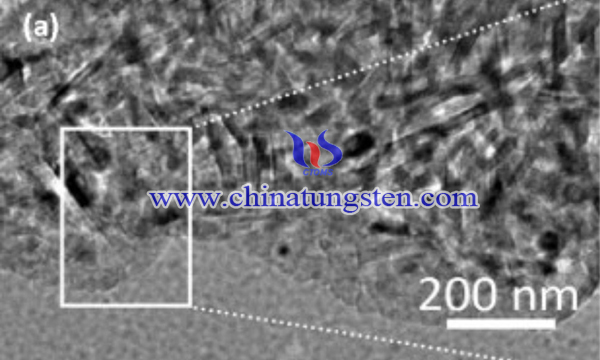

The WO3 nanostructured films were sputtered onto pre-fabricated interdigitated (IDT) electrodes made of SiO2/Si based substrates. Thin layers of SiO2 (~300 nm), Cr (~50 nm) and Au (~100 nm) were successively electron-beam evaporated onto the Si substrates. Once these steps were completed, a standard photolithographic patterning process was applied to obtain the IDT. The Au/Cr IDTs contained 8 finger pairs with spacing of 50 μm. Prior to WO3 deposition, the fabricated transducers were cleaned successively with acetone and isopropanol under ultrasonication and dried in a flow of nitrogen (N2). Once ready, the samples were attached on a substrate holder and loaded into the deposition chamber.

WO3 nanorods were deposited in a variable angle RF magnetron sputtering system. The sputtering target was a 3-inch tungsten disc with 99.995% purity (K.J. Lesker). The distance from the target to substrate center and the substrate rotation were set at 7 cm and 30 rpm, respectively. The substrate normal was positioned at an angle of 85° with the respect to the vapor incident flux (the vertical axis). The chamber was evacuated by rotary and turbo molecular pumps (Pfeiffer Inc.), while the vacuum pressure was continuously monitored with Pirani and Penning pressure gauges to a base pressure of 5.6 × 10−6 mbar. The tungsten target was then reactively sputtered in a mixture of 99.999% argon (Ar) and 99.999% oxygen (O2) at controlled flow rates of 9.6 and 11.0 sccm, respectively. The plasma discharge was generated at a constant RF power of 200 W at a sputtering pressure of 5.0 × 10−3 mbar. The film thicknesses were varied by changing sputtering time from ½ to 2 h. The samples deposited at ½, 1, and 2 h were labeled as W1, W2 and W3, respectively. The fabricated samples containing WO3 based thin-films were then annealed in air at 450 °C for 2 h with a ramp up/down of 2 °C/min.

In conclusion, RF sputtered nanosized tungsten trioxide has been fabricated targeting gas sensing of NOx and ethanol, the produced sensors possess good baseline stability, good repeatability, and high and fast response/sensitivity. The sensors were exposed to both the reducing (C2H5OH) and oxidizing (NO2) analytes. The ethanol response of WO3 nanorods based thin-film was found to increase with decreasing film thickness, and a maximum response of 10 for C2H5OH of 200 ppm was obtained from the thinnest sensing film at the optimized operating temperature of 300 °C. On the contrary, the NO2 response was enhanced with increasing WO3 nanorods film thickness, and the thickest films exhibited a very large response of 1075 (10 ppm of NO2) at a relatively low optimized operating temperature of 150 °C.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com