Synthesis of WO3/Bivo4 Heterojunction Nanorod via Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Monday, 01 February 2021 19:35

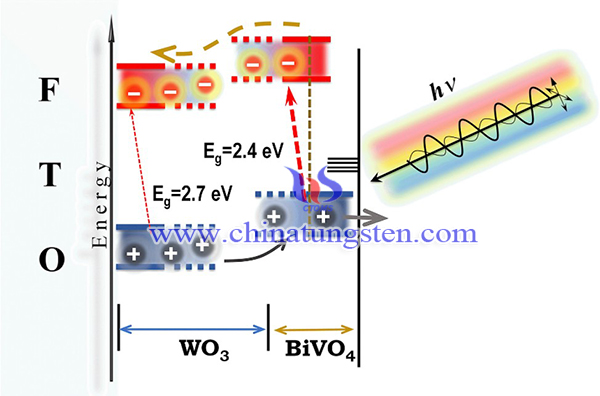

Direct solar water splitting driven by inexpensive semiconducting materials is an attractive method to produce hydrogen as a zero-greenhouse gas emission fuel. During the past three decades, however, it has been shown that the main challenge consists in identifying materials that are stable under illumination in aqueous solutions, efficiently absorb sunlight, and induce efficient water splitting. Due to their inherent stability against oxidation and low cost, semiconducting oxides are promising materials to be employed in this process. Unfortunately, relatively fast recombination of photogenerated charge carriers, either in the bulk or at the surface, and slow charge transfer kinetics from the semiconductor to the electrolyte solution restrict their performance.

A preparation method of WO3/BiVO4 heterojunction nanorod using ammonium paratungstate as raw material has been conducted. The material is considered as feasible for application in solar water splitting systems.

The experimental design as below had been conducted:

The WO3 porous films were synthesized as follows: 1 g ammonium paratungstate (APT) was heated in lactic acid until complete dissolution to get a final concentration of 10% wt. Then, 1 mL of the solution was diluted 10 times by volume with ethanol to obtain the seed layer precursor solution. The precursor solution was deposited onto the substrate via spin-coating at 3000 rpm for 15 s, and the coated substrates were subsequently annealed at 500 °C for 3 h in a furnace. The substrates covered with a seed layer were then placed into a Teflon-lined hydrothermal reactor with 1.25 g of the ammonium paratungstate solution (10 wt %), 8.75 g lactic acid, 20 g ethanol, and 0.1383 g reduced l-glutathione (C10H17N3O6S). The reactor was positioned into a stainless-steel autoclave and heated at 200 °C for 4 h. The obtained films were annealed in air at 550 °C for 1 h.

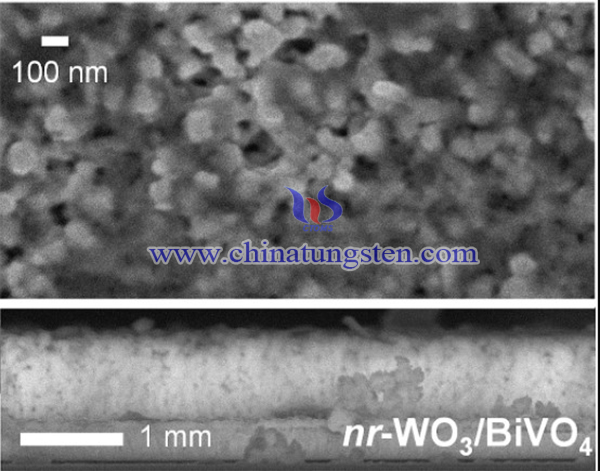

On top of the porous, nanorod WO3 films, a layer of BiVO4 was prepared by spin-coating using the same precursor solution as for the planar film, and the nr-WO3/BiVO4 heterojunction was annealed in a rapid thermal annealing furnace at 500 °C for 120 s. The procedure was repeated 3 times and the final, complete stack was annealed at 500 °C for 2 h in an air atmosphere. X-ray diffraction (XRD), scanning electron microscopy (SEM) were used to characterized the product.

Conclusion

WO3/BiVO4 heterojunction nanorod have been prepared using hydrothermal synthesis and spin coating. the WO3 surface is protected by BiVO4, and electron extraction from BiVO4 is sufficiently efficient to prevent surface recombination. At 455 nm, the nr-WO3/BiVO4 achieves quantitative water oxidation under illumination at potentials more positive than about 0.9 V(RHE) indicating its promise for application in solar water splitting systems.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com