Production of Tungsten-Copper Composite Via Ammonium Paratungstate Enhanced by Jet Milling

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 February 2021 19:23

Tungsten–copper (W–Cu) composites are extensively used in aerospace, military equipment, electronics, and chemical engineering because of their merits, like high electrical/thermal conductivity, low coefficient of thermal expansion (CTE), and outstanding strength/thermal properties of W.

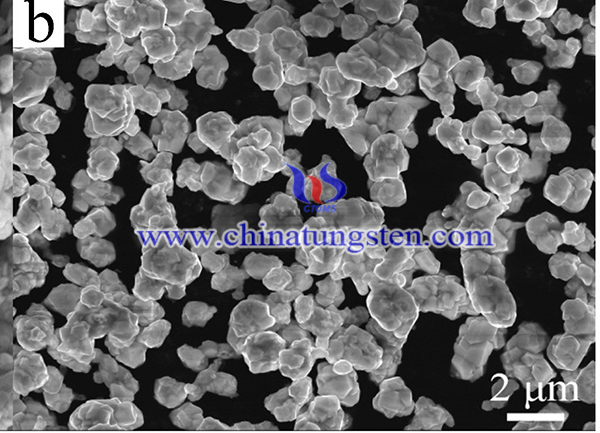

Nevertheless, there exhibits drawbacks of high-density and uniform microstructure in W–Cu parts when employing ultrafine or nano-level W–Cu composite powders. To get over these disadvantages, Jet milling (JM) method were W–10 wt.%Cu (W–10Cu) composite was used to enhance its particle size distribution and microstructures.

The synthesis procedure can be divided into 2 major steps:

Ammonium paratungstate (APT,), copper nitrate (Cu(NO3)2·3H2O), deionized water, and citric acid (C6H8O7·2H2O) were used as received.

1) W–10Cu powders

The raw materials used to prepare W–10Cu powders were APT and (Cu(NO3)2·3H2O. W–10Cu powders were fabricated from sol-spray drying, calcination and a subsequent hydrogen reduction process. In a typical process, 27.18 kg of Cu(NO3)2·3H2O, 91.4 kg APT, and moderate amounts of citric acid were initially added into 300 L of deionized water. The mixture was stirred at 90 °C for 30 min. The solution was then spray-dried and subsequently calcined at 600 °C for 4 h to obtain the oxide mixture. Finally, W–10Cu powders were obtained by the following hydrogen reduction processes at 800 °C for 3 h in a flowing hydrogen atmosphere.

2) JM process

The procedures were carried out on LHC-6 fluidized bed jet mill equipped with a grading wheel under high-purity nitrogen atmosphere. The equipment is made of 304 stainless steel, Fe, Cr, Ni and other impurities may be introduced when the high-speed powders collide with the inner wall. In order to reduce the impurities introduced during JM process, a layer of rubber is pasted on the inner wall of the equipment, and the surface of the grading wheel is sprayed with tungsten carbide coating. The machining parameters were set as follow: the feed mass was kept constant at 5 kg per hour, the gas pressure was set at 0.70 MPa, and the speed of the grading wheel is 4200 rpm.

Conclusion

Ultrafine W–10Cu powders from ammonium paratungstate and applying JM were successfully produced. The powder has the advantages of high powder loading, excellent properties, and good size stability. The agglomeration of powders considerably decreased, the surface became increasingly smooth, the particle size distribution range of the JM powders became narrow, the tap density increased, and negligible impurities were introduced. After JM, the powder volume fraction of the feedstock increased from 46 vol.% to 52 vol.%. The sintered composite shows fine and homogeneous microstructures.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com