Preparation Method of Tungsten Trioxide Graphene Composite Material (Ⅰ)

- Details

- Category: Tungsten Information

- Published on Thursday, 27 August 2020 14:10

Tungsten trioxide is an n-type wide-band gap semiconductor oxide with low price, easy preparation, stable performance, non-toxic and harmless, and has been widely used in the field of photoelectrochemistry.

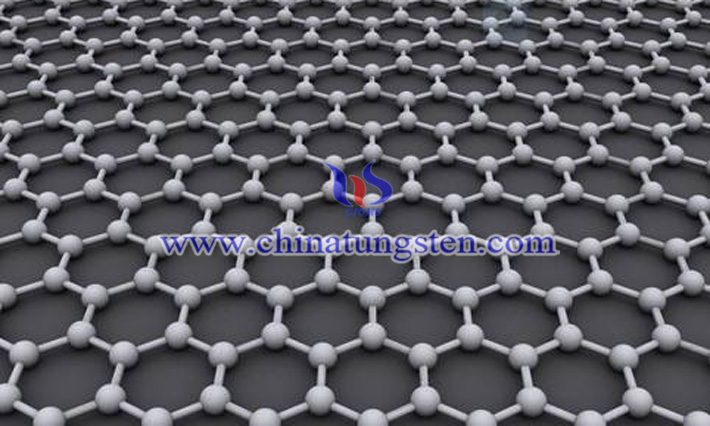

If WO3 is compounded with graphene, it will help expand the specific surface area of tungsten oxide and increase the contact area, thereby improving its chemical activity. It shows broad application prospects in the fields of gas detection, light detection, catalysis, and energy storage. Below is the preparation method of tungsten trioxide/nitrogen doped graphene composite.

At present, various methods for synthesizing graphene-supported tungsten trioxide nanocomposites can be divided into two categories according to whether tungsten trioxide is generated in situ on graphene: in-situ synthesis technology and ex-situ synthesis technology, of which water/solvothermal method It is the most widely used in-situ synthesis technology for the synthesis of sulfide graphene-based composite nanomaterials.

Because graphene oxide contains oxygen-containing functional groups, it can be uniformly dispersed in water and can be easily synthesized in large quantities. It has become the most commonly used raw material. For example, Fang Fang et al. use (NH4)10H2(W2O7)6 as tungsten source, oxalic acid as precipitant, and ammonium sulfate as morphology modifier, hydrothermally treated at 180°C for 24 h, washed and dried, and then treated in an argon atmosphere at 800°C for 2h to synthesize a tungsten trioxide/graphene composite.

Jie Lian et al. used Na2WO4•2H2O as the tungsten source and NaCl as the morphology improver, added to the graphene oxide dispersion, adjusted the pH to 2 with 2M hydrochloric acid, and hydrothermally treated it at 180°C for 24h. After centrifugal washing and drying, tungsten oxide/graphene composite is obtained.

Kyung-Won Park et al. disperse a certain amount of graphene oxide ultrasonically in 5M hydrochloric acid, then add (NH4)10H2(W2O7)6 ultrasonically to dissolve it, hydrothermally heat it at 140℃ for 6 hours, wash and dry, and then pass it through 450℃, calcined at high temperature for 2h to obtain tungsten trioxide/graphene composite.

The hydrothermal/solvothermal synthesis of tungsten trioxide/graphene composite nanomaterials is characterized by fewer synthesis steps and no additional reducing agent, but the synthesis requires high pressure and a long time.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com