Metallization of Alumina Single Crystal Tungsten Yttrium

- Details

- Category: Tungsten Information

- Published on Saturday, 03 August 2019 23:38

Metallization modification of the welded surface of alumina composite single crystal is the precondition of reliable sealing with metal. Conventional molybdenum-manganese metallization process, sintering temperature is generally about 1400 ℃, later welding or use process exceed this temperature, the glass phase in the metallized layer will flow, destroy the metallized layer, thereby affecting the sealing strength and sealing gas tightness of ceramics-metal and other properties. Moreover, the low metallization sintering temperature also limits the selection of high temperature quinone solder for sealing alumina composite single crystal with metal, and directly limits the high temperature use of sealing parts.

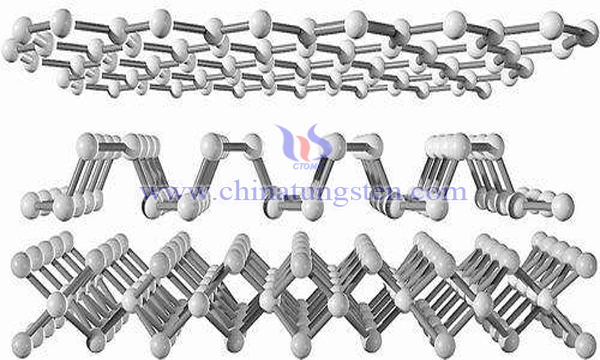

Scientists used W-Y2O3 activation metallization process for the metallization of alumina single crystal, and tungsten yttrium oxide composite powders prepared by co-deposition method for the metallization of alumina single crystals. The surface metallization modification of alumina single crystals was completed by secondary pasting and sintering process. The specific operation of this process includes:

(1) Pretreatment of alumina composite single crystal before metallization

Firstly, the surface of alumina composite single crystal was ground and polished, and then cleaned.

(2) Preparation of tungsten yttrium oxide composite powder

Hydrazine oxalate and ammonium yttrium oxalate composite salts were prepared by chemical co-deposition with tungstic acid, yttrium nitrate, oxalic acid and hydrazine hydrate, and then pyrolyzed and reduced to obtain tungsten yttrium oxide composite powder.

(3) Alumina composite single crystal metallized primary paste

Tungsten yttrium oxide composite powder was pasted with cotton nitrate solution and uniformly coated on the surface of alumina composite single crystal. The coating thickness ranged from 30 to 40 microns.

(4) Low temperature metallization sintering of alumina composite single crystal

Aluminum oxide composite single crystals which were first pasted were sintered at low temperature in hydrogen atmosphere.

(5) Alumina composite single crystal was metallized twice with paste thickness of 20-30 um.

(6) Alumina composite single crystal metallized high temperature sintering

Aluminum oxide composite single crystals with second paste were sintered at high temperature in hydrogen atmosphere. The results show that the metallized layer on alumina surface is compact, high strength and uniform in quality. Moreover, the activated tungsten metallized alumina single crystal can be welded with high temperature solder, and the service temperature of the sealing parts is obviously increased.

The metallized layer prepared by the process has strong bonding force with alumina composite single crystal, no skin and uniform thickness, which provides a reliable guarantee for the high air tightness and high strength sealing of alumina composite single crystal with metal in the later stage.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com