Cadmium Sulfide-molybdenum Sulfide- sulfur Tungstenheterojunction Photocatalytic Composite

- Details

- Category: Tungsten Information

- Published on Friday, 02 August 2019 00:45

In the field of inorganic semiconductor materials, cadmium sulfide is a typical semiconductor. The CdS photocatalyst has a band gap of 2.4 eV at room temperature, and the conduction band potential (-0.87 eV) and valence band potential (1.5 eV) can meet the conditions of complete photolysis of water. . Therefore, cadmium sulfide can improve the utilization of sunlight and become one of the most attractive semiconductor catalysts in sulfide systems.

However, when CdS is not surface-modified and modified, the hydrogen decomposition activity of photodecomposition water is not high, and due to the photo-corrosion, cadmium sulfide will undergo photolysis when exposed to long-time illumination, resulting in a decrease in its activity.

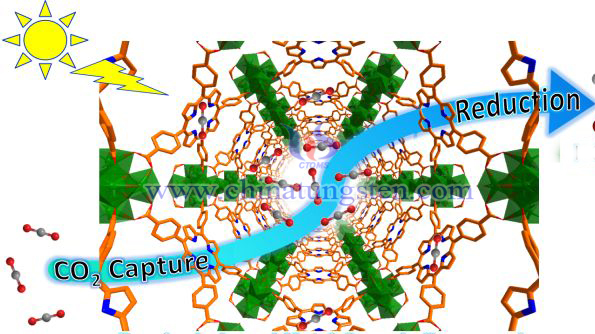

In order to solve the above problems, some scholars have simultaneously loaded MoS2 and WS2 as cocatalysts on CdS semiconductor photocatalysts to form a multi-component transition metal sulfide composite photocatalyst with synergistic effect, broadening the response range to visible light, thereby expressing excellent photocatalytic hydrogen production performance and good stability, the synthesis process of cadmium sulfide-molybdenum sulfide-sulfur tungsten heterojunction composite photocatalyst includes:

S1: Adding cadmium diethyldithiocarbamate (CED), molybdenum diethyldithiocarbamate and diethyldisulfide with a mass ratio of 2:1:2 to an appropriate amount of organic solvent ethylene glycol The tungsten carbamate was thoroughly stirred with a magnetic stirrer and uniformly mixed to obtain a precursor reaction liquid.

S2: Performing a two-stage microwave heating constant temperature reaction of the precursor reaction solution to obtain a cadmium sulfide-molybdenum sulfide-sulfur tungsten heterojunction photocatalytic composite material, specifically: the precursor obtained in step S1 under a microwave power of 200 W The reaction solution is heated from room temperature to 90 ° C and maintained at this temperature for 10 minutes to obtain a first reaction liquid; the first reaction liquid is further heated to 160 ° C at a microwave power of 500 W, and at the temperature Hold for 10 minutes to obtain a second reaction solution; finally, the second reaction solution was naturally cooled to room temperature, and centrifuged at 15,000 rpm for 5 minutes, and the resulting precipitate was washed successively with absolute ethanol and deionized water. After 3 times, and then vacuum drying, a cadmium sulfide-molybdenum sulfide-sulfur tungsten heterojunction photocatalytic composite material was obtained.

The cadmium sulfide-molybdenum sulfide-sulfur tungsten heterojunction photocatalytic composite material obtained by specific specific morphology can be prepared by photolysis of water under light conditions, and has a very excellent hydrogen production rate for photolysis. Hydrogen production provides new and efficient photolysis composites with enormous application potential and industrial value in the industrial field.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com