An Effective Synthesis Process of Tungsten Oxide Nanowires

- Details

- Category: Tungsten Information

- Published on Friday, 02 August 2019 00:35

Tungsten oxide is an n-type semiconductor and is a typical transition metal oxide. As a functional material, it is applied to industrial catalysts, electrochromic, battery electrodes, solar energy absorbing materials, invisible materials, gas sensing materials, and the like. Especially in the field of oxide semiconductor gas sensor applications, tungsten oxide-based materials have been considered as one of the most promising new oxide gas sensing materials for detecting NOx, SOx, NH3 and H2S.

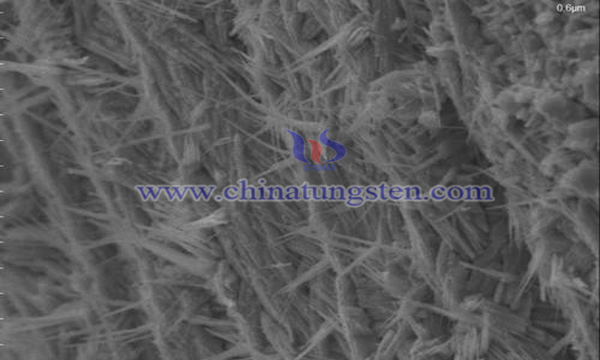

Compared with conventional tungsten oxide materials, tungsten oxide nanowires have a larger specific surface area, and have greater surface activity and stronger adsorption capacity. It speeds up the reaction with the gas, which greatly increases sensitivity and further reduces the operating temperature of the sensor.

However, at present, the technology for preparing tungsten oxide nanowires has many problems such as complicated preparation process and high energy consumption. In view of the problems existing in the preparation process of tungsten oxide nanowire materials, some scholars have prepared a large-scale tungsten oxide nanowire material with a simple sol-gel synthesis method. The specific operation steps include:

1) Preparation of sol

Accurately weigh a certain amount of P123, WCl6 and excellent pure ethanol, so that the weight ratio of P123, WCl6 and excellent pure ethanol is 0.5:1:10. Weigh the weighed P123 first. In pure ethanol, the magnetic stirring was carried out until P123 was completely dissolved, and magnetic stirring was carried out until WCl6 completely dissolved and a pale yellow sol was formed.

2) Filling the AAO template

The sol just prepared in the above 1 is filled in the AAO template under a pressure of -0.1 MPa;

3)Pre-processing after filling the AAO template

The sol-filled template was washed three times with absolute ethanol and deionized water, and then dried in a vacuum oven at 60 ° C for 10 hours;

4)Setting of sintering temperature curve

A period of 5 hours was set to raise the chamber of the atmosphere furnace from room temperature to a maximum temperature of 500 ° C, and maintained at this temperature for 5 hours, and then naturally cooled from room temperature to 500 ° C to room temperature.

5) Atmospheric sintering to prepare tungsten oxide nanowires

The dried sample was sintered at 500 ° C for 5 hours in a high-purity argon atmosphere, and then naturally cooled to room temperature, and the sample was taken out to obtain a tungsten oxide nanowire having a strange morphology.

The above synthesis process is simple, the process parameters are easy to control, has lower energy consumption, and tungsten oxide nanowires prepared are peculiar in appearance and have a large specific surface area.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com