New Tungsten Cobalt Carbide Thermal Spraying Coating

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 February 2019 22:42

When using traditional WC-17Co thermal spraying powder, its crack resistance is better than that of WC-12Co spraying powder because of its high cobalt content, but its hardness is relatively low. When the hardness of the coating is increased by adjusting, the toughness of the coating decreases obviously. How to achieve a balance between toughness and hardness? Therefore, some scholars have found a way to synthesize tungsten carbide coating materials.

A new type of tungsten cobalt carbide thermal spraying powder is composed of two different particle sizes of tungsten carbide, cobalt and trace titanium carbide. The mass percentage of tungsten carbide is 83%, that of cobalt metal is 16.5%, and that of titanium carbide, a grain inhibitor, is 0.5%. The synthesis steps are as follows:

A. Preparing materials:

The nano-tungsten carbide with a mass percentage of 25-58% and a particle size of 0.05-0.2 micron was prepared. The prepared tungsten carbide with a mass percentage of 25-58% and a particle size of 2.0-8.0 micron was prepared.

B. Mixture:

Firstly, according to the process requirements, nano-tungsten carbide, medium-sized tungsten carbide and 16.5% cobalt powder were added to the ball milling equipment in step A. Then, deionized water and polyvinyl alcohol, which accounted for 25% of the raw material mass and 2.0% of the mass, were added to the ball milling equipment. The milling time was 22-28 hours, and titanium carbide, which was a grain growth inhibitor with 0.5% of the mass percentage, was added.

C. Granulation:

An open centrifugal spray drying tower was adopted to dry granulation and spherical mixture was obtained. The centrifugal atomizing disk was rotating at 8000 to 12000 rpm.

D. Sintering:

The mixture is loaded into graphite boat vessel, placed in molybdenum wire furnace and sintered continuously in hydrogen atmosphere. The pushing speed of boat is 9-12 minutes per boat, and the sintering temperature is 950-1250 ℃.

E.Fragmentation classification:

After sintering, the product is crushed by mechanical method, and the final product thermal spraying powder is obtained by sieving or airflow grading according to the size distribution range. The particle size is 15-45 micron, and the bulk density is 4.0-5.8 g/cm3.

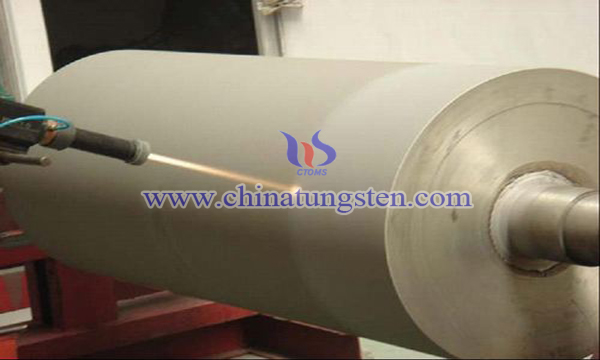

Tungsten cobalt carbide thermal spraying powder is mainly used for supersonic high-speed flame spraying or other thermal spraying coating preparation process, so the particle size distribution of thermal spraying powder is between 5 and 75 microns. The new process can effectively adjust the hardness, toughness and other related properties of the coatings after powder spraying by adjusting the different components of nano-tungsten carbide powders to prepare thermal spraying powders with different requirements and uses, so that their comprehensive properties can reach a higher level.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com