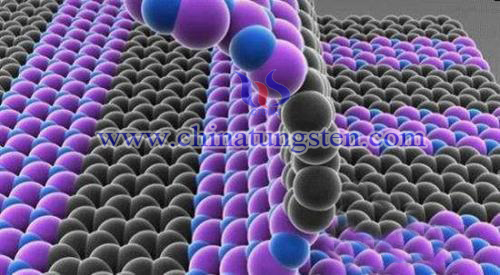

Tungsten Disulfide/Graphene Nanoribbon Composites

- Details

- Category: Tungsten Information

- Published on Sunday, 09 December 2018 19:36

Tungsten disulfide is a typical transition metal chalcogenide. It belongs to hexagonal crystal system. It has a strong S-W-S covalent bond in the layer and a weak van der Waals force between the layers. The thickness of the single layer is about 0.65 nm. Monolayer tungsten disulfide nanosheets can be obtained by stripping or lithium ion intercalation.

The results show that the active edge exposed to tungsten disulfide has catalytic activity for hydrogen evolution, so it is widely used in the field of electrochemical catalysis. However, pure tungsten disulfide is easy to agglomerate, and it preferentially grows inert inner structure rather than active lamellar edge. A large number of aggregates also further inhibit the exposure of active edge. In addition, its poor electrical conductivity, the excellent properties of pure tungsten disulfide will not be fully utilized. For this reason, some scholars have advanced the two methods. Composite materials with excellent properties were prepared by effective compounding.

(1)150 mg multi-walled carbon nanotubes were dispersed in 98% concentrated sulphuric acid, and 85% phosphoric acid was added after uniform dispersion. In this process, uniform dispersions were obtained by continuous stirring.

(2)750 mg potassium permanganate was added into the above dispersions in batches and stirred continuously.

(3)The reaction system was slowly heated to 70 ℃. After the temperature was stabilized, the reaction system was kept warm for a period of time and stirred continuously.

(4)Cool the mixed dispersions to room temperature naturally, then pour them into ice water containing 7 mL 50% hydrogen peroxide and place them overnight to make them settle naturally.

(5)The precipitate was washed many times with 10% hydrochloric acid solution, and then with ethanol/ether mixed solution for many times.

(6)Solid graphene oxide nanoribbons were obtained by centrifugal drying.

(7)Graphene oxide nanoribbons were dispersed in N, N-dimethylformamide, and stable dispersion of 1 mgmL-1 graphene oxide nanoribbons was obtained by ultrasound.

(8) 11 mg ammonium thiotungstate was dissolved in 10 mL graphene oxide nanoribbon dispersion solution, which was uniformly dispersed by ultrasound.

(8)0.2 mL 50% hydrazine hydrate was dripped into the mixture of graphene oxide nanoribbons and ammonium thiotungstate, and the ultrasonic dispersion was uniform.

(10) The prepared dispersions containing graphene oxide nanoribbons, ammonium thiotungstate and hydrazine hydrate were put into a hydrothermal autoclave and hydrothermal reaction was carried out at 240 ℃ for 12 hours. The prepared black precipitates were washed repeatedly with deionized water and ethanol, and then tungsten disulfide nanosheets/graphene nanoribbon composites were obtained.

Tungsten disulfide/graphene nanoribbon composites can be used as high performance catalyst materials and ideal electrode materials for new energy sources such as lithium ion batteries and solar cells.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com