Thermal Stability of Tungsten Wire in Heating Glass Equipment

- Details

- Category: Tungsten Information

- Published on Friday, 27 June 2025 17:13

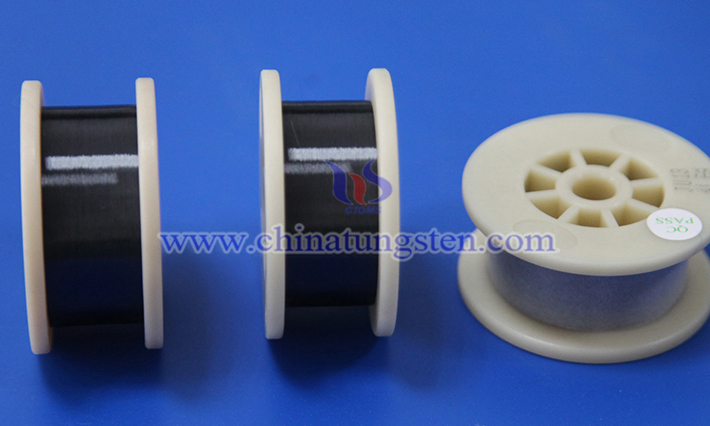

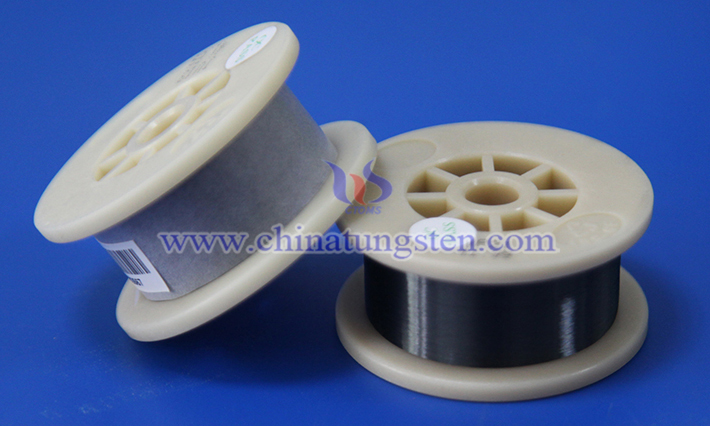

Tungsten wire exhibits excellent thermal stability in heating glass equipment due to its ultra-high melting point, low vapor pressure, excellent high temperature strength, good creep resistance (especially non-drooping tungsten wire) and low thermal expansion coefficient, making it an ideal choice for high temperature heating elements.

1. High Melting Point

Tungsten has the highest melting point of all metal elements, reaching an astonishing 3422°C. This allows tungsten wire to remain solid in an environment far higher than the melting temperature of most other metals, meeting the high temperature requirements required for glass processing or equipment operation (usually in the range of 1500°C to 3000°C).

2. Low Vapor Pressure

At high temperatures, tungsten has a relatively low vapor pressure. This means that in a vacuum or inert gas environment, the rate at which tungsten wire loses material due to evaporation is very slow, thus ensuring its dimensional stability and life for long-term use. This is critical for heating glass equipment (such as vacuum tubes) that need to maintain precise shapes for a long time or avoid contaminating a closed environment.

3. Excellent High-Temperature Strength

Even in a white-hot state close to its melting point, tungsten can still maintain a high strength and rigidity. This allows the tungsten wire to withstand certain mechanical stresses (such as its own gravity, thermal expansion stress, and slight tension during installation) at high temperatures, and is not prone to sagging, deformation, or breakage. This is the key to maintaining the shape and function of the heating element.

4. Good Creep Resistance

Under high temperature and continuous stress, the material will undergo slow and permanent deformation (creep). Tungsten has relatively good creep resistance, especially in "non-drooping tungsten wire" doped with specific elements (such as potassium, silicon, aluminum, etc.). This doping process effectively inhibits grain growth and grain boundary sliding by forming stable potassium bubbles at the grain boundaries, greatly improving the ability of tungsten wire to resist sagging and deformation at high temperatures, which is one of its core advantages in thermal stability.

5. Low Thermal Expansion Coefficient

Tungsten has a relatively low thermal expansion coefficient (about 4.5×10⁻⁶/K in the range of room temperature to 1000°C). This means that the dimensional changes of tungsten wire are relatively small during heating and cooling cycles. When tungsten wire needs to be used with glass parts (such as sealing ends or support structures), the lower thermal expansion coefficient helps to reduce the thermal stress caused by thermal expansion mismatch, improve the reliability of sealing and the overall stability of the device.

6. Chemical Stability (Under Specific Environments)

In a vacuum or inert gas (such as argon, nitrogen) environment, tungsten is very stable at high temperatures and is not prone to chemical reactions. However, in an oxygen-containing atmosphere, tungsten will quickly oxidize to volatile tungsten trioxide (WO₃) at high temperatures, resulting in rapid failure. Therefore, the application of tungsten wire depends on maintaining an oxygen-free or reducing environment.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com