Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Friday, 27 June 2025 18:47

Tungsten-nickel-iron alloy is an important tungsten-based high-density alloy. By definition, it is an alloy composed of adding nickel and iron to metallic tungsten, with the nickel-iron ratio typically maintained at 7:3 or 1:1. With excellent comprehensive properties, this type of alloy is widely applied and has become the main category of tungsten-based alloys with large usage at present.

In tungsten-nickel-iron alloy, the tungsten content generally ranges from 90% to 98%, making tungsten the matrix of the alloy and playing a fundamental role. The remaining part is mainly composed of nickel and iron as the bonding phase, which tightly combines high-melting-point and high-density tungsten particles, endowing the alloy with good strength and plasticity. Due to such a unique composition, tungsten-nickel-iron alloy possesses a series of excellent properties and demonstrates important value in numerous fields.

I. Unveiling the Characteristics of Tungsten-Nickel-Iron Alloy

1. Density and Specific Gravity

One of the prominent characteristics of tungsten-nickel-iron alloy is its high density, generally with a specific gravity of 16.5-18.75 g/cm³. This high-density feature enables it to play a key role in many fields. For example, in the aerospace field, tungsten-nickel-iron alloy is used to manufacture the gyro rotor of aircraft. Since the gyro rotor needs to accurately sense the attitude change of the aircraft, the high-density tungsten-nickel-iron alloy ensures that the rotor has higher stability and inertia during high-speed rotation, thereby improving the accuracy of the gyroscope, enabling more precise control of the aircraft's flight attitude, and ensuring flight safety.

2. Mechanical Properties

Tungsten-nickel-iron alloy also performs excellently in mechanical properties. It has high strength, with a tensile strength usually ranging from 700 to 1000 Mpa, as well as good plasticity and workability. This series of excellent mechanical properties is particularly important for manufacturing complex components. Take the crankshaft of an automobile engine as an example: the crankshaft needs to bear huge alternating loads during engine operation. Using tungsten-nickel-iron alloy to manufacture the crankshaft, its high strength can effectively resist these loads, preventing the crankshaft from deforming or breaking during long-term operation; good plasticity allows the crankshaft to be accurately processed into the required complex shape through forging, machining, and other processes during processing, meeting the high-precision requirements of the engine and ensuring the stable and efficient operation of the engine.

3. Radiation Absorption Capacity

It is worth mentioning that tungsten-nickel-iron alloy also has strong radiation absorption capacity, which is 30-40% higher than that of traditional radiation protection materials like lead. In the medical field, equipment such as CT machines and linear accelerators generate a large amount of radiation. Due to its high density and good workability, tungsten-nickel-iron alloy is made into protective doors, collimators, main shielding walls, and other components, which form a multiple protection system with materials like glass and concrete. This can control the radiation leakage within safe limits and effectively protect medical staff and patients. In the nuclear power field, nuclear reactors in nuclear power plants generate strong γ rays, and shielding materials made of tungsten-nickel-iron alloy can effectively shield these rays, ensuring the safety of nuclear power plant workers and the radiation safety of the surrounding environment.

4. Other Characteristics

In addition, tungsten-nickel-iron alloy has other characteristics. It has a high thermal conductivity, which makes it applicable in scenarios requiring rapid heat dissipation, such as radar transmitter modules that need to meet both heat dissipation and radiation shielding. Its low coefficient of thermal expansion enables the material to maintain dimensional stability in environments with large temperature changes. For example, this property is utilized in high-temperature components of aircraft engines to ensure that components will not affect performance due to thermal expansion and contraction under high-temperature working conditions. Moreover, tungsten-nickel-iron alloy has certain ferromagnetism, which has special applications in some electromagnetic devices, such as magnetic sensors; it also has good electrical conductivity and weldability. Good electrical conductivity makes it widely used in the lighting and electric welding industries, while weldability facilitates the connection with other components during manufacturing, further expanding its application scope.

II. Introduction to the Preparation Process of Tungsten-Nickel-Iron Alloy

The most commonly used process for preparing tungsten-nickel-iron alloy by CTIA GROUP LTD is powder metallurgy, and its main steps include:

1. Ingredients

According to the required composition and performance of the alloy, high-purity and appropriately sized tungsten powder, nickel powder, and iron powder are accurately weighed. For example, to prepare a 95W3Ni2Fe alloy, ingredients should be carried out according to the ratio of 95% tungsten, 3% nickel, and 2% iron. Sometimes, some other trace additives may be added, such as adding a small amount of cobalt to further improve the strength and hardness of the alloy under certain special requirements.

2. Ball Milling

The mixed powder is put into a ball mill, and an appropriate amount of grinding medium is added. During ball milling, the powder collides and rubs with the grinding medium, further refining the powder particle size and making various components more uniformly mixed. Parameters such as ball milling time, rotation speed, and the type and quantity of grinding medium will affect the ball milling effect. Generally, the longer the ball milling time, the finer the powder particle size and the more uniform the mixing. However, too long a ball milling time may introduce impurities and increase production costs, so optimization is needed according to actual situations.

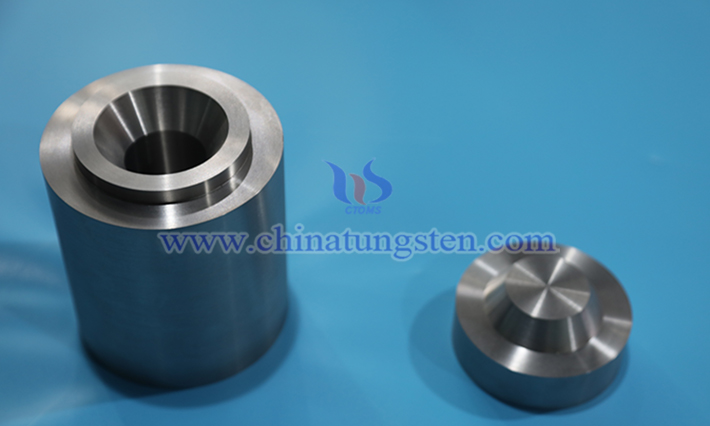

3. Compression Molding

The mixed powder is put into a specific mold and formed under a certain pressure to obtain a green body with a certain shape and size. Factors such as pressing pressure, pressing method, and mold design will affect the quality and performance of the green body. For example, using isostatic pressing can make the green body receive uniform pressure in all directions, thereby obtaining a green body with more uniform density, which is suitable for manufacturing products with complex shapes or high requirements for density uniformity.

4. Sintering

The pressed green body is put into a high-temperature furnace for sintering to densify it. During sintering, protective gases such as hydrogen and nitrogen are usually introduced to prevent the alloy from oxidizing at high temperatures. The sintering temperature should be controlled within a reasonable range to ensure that the atoms in the alloy diffuse sufficiently, promote the bonding between particles, and improve the density and strength of the alloy. At the same time, the sintering time will also affect the properties of the alloy. A longer sintering time can make the alloy more dense, but it may also lead to grain growth and reduce the toughness of the alloy, so the sintering temperature and time need to be precisely controlled.

The tungsten-nickel-iron alloy prepared by the above powder metallurgy process has high density and good comprehensive properties. Of course, in actual production, process parameters will be optimized and adjusted according to different product requirements and application scenarios to meet persified production needs.

III. Wide Application Fields of Tungsten-Nickel-Iron Alloy

1. Industrial Counterweights

In the industrial field, tungsten-nickel-iron alloy is often made into counterweight components for balancing and stabilizing various equipment or products. In the aerospace field, precise counterweights are required for the wings, tail wings, and other parts of aircraft to ensure the stability and maneuverability of the aircraft during flight. The counterweight blocks made of tungsten-nickel-iron alloy can provide sufficient weight within a limited space. At the same time, due to their high strength and good corrosion resistance, they can ensure long-term stable operation in harsh flight environments. In the automotive industry, the crankshafts, transmissions, and other components of some high-performance racing cars use tungsten-nickel-iron alloy counterweights to optimize the moment of inertia of the components and improve the performance and response speed of the engine. In sports equipment, the heads of golf clubs use tungsten-nickel-iron alloy counterweights to adjust the center of gravity distribution of the clubs, making it easier for players to control the hitting force and direction and improve the accuracy and distance of hitting.

2. Radiation Protection and Guidance

Due to its strong radiation absorption capacity, tungsten-nickel-iron alloy plays an important role in medical equipment, radiotherapy, nuclear medicine, and other fields. In the fields of radiotherapy and nuclear medicine, components such as collimators and multi-leaf gratings made of tungsten-nickel-iron alloy can accurately guide and control the direction and intensity of radiation, making the radiation accurately irradiate the lesion site, improving the treatment effect, and reducing damage to surrounding normal tissues. In the nuclear industry, tungsten-nickel-iron alloy is often used to manufacture shielding components of nuclear reactors, radioactive material storage containers, etc., which can stably block radiation in complex radiation environments, ensure equipment safety and personnel health, and are important materials for radiation protection in the nuclear industry.

3. Security and Defense

In the field of national defense and military industry, tungsten-nickel-iron alloy has become an important material for manufacturing key components such as armor-piercing projectile cores by virtue of its high density, high strength, and high penetration capacity. When an armor-piercing projectile hits a target, it needs strong penetrating power to penetrate targets such as tank armor and strong defense. The projectile core made of tungsten-nickel-iron alloy has a large density, which can carry huge kinetic energy during high-speed flight, and has good strength and hardness, making it not easy to deform or break during impact, thus effectively penetrating the target. In addition to armor-piercing projectile cores, tungsten-nickel-iron alloy is also used in the counterweight components of some missiles to adjust the center of gravity of the missiles, improve the flight stability and hit accuracy of the missiles.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com