Tungsten-Nickel-Copper Alloy

- Details

- Category: Tungsten Information

- Published on Friday, 27 June 2025 18:53

In the vast field of materials science, tungsten-nickel-copper alloy (W-Ni-Cu) shines like a brilliant star, exuding unique charm. As a high-performance material with tungsten as the matrix and alloying elements such as nickel and copper, it is known as the "versatile player" in the industrial field, playing an indispensable role in many key industries. From the high-tech aerospace sector to the manufacturing of daily electronic devices, its presence is ubiquitous. Let us now delve into the wonderful world of tungsten-nickel-copper alloy, exploring its composition, unique properties, and extensive applications.

I. Definition and Composition Analysis of Tungsten-Nickel-Copper Alloy

Tungsten-nickel-copper alloy, abbreviated as W-Ni-Cu, is an important alloy composed of tungsten as the matrix with the addition of trace elements like nickel and copper. It combines multiple excellent properties, playing a crucial role in various industrial fields.

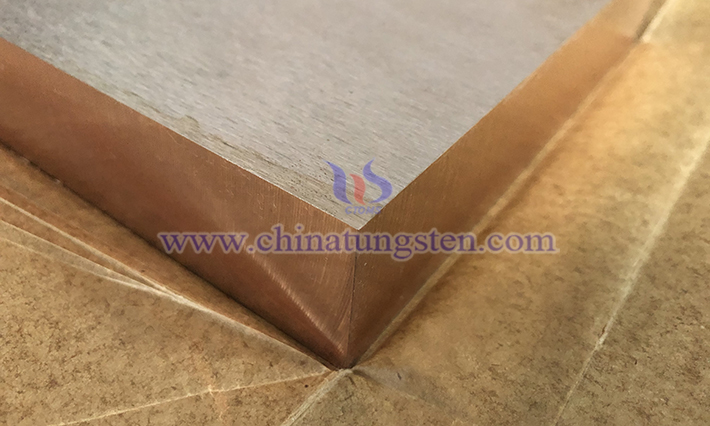

In common W-Ni-Cu alloy formulations, the addition ratio of nickel to copper is typically 3:2. This specific ratio is not arbitrarily determined but verified through extensive experiments and practices, achieving an optimal balance among multiple properties. With tungsten as the main component (content usually between 85%-99%), the alloy inherits tungsten's fundamental characteristics such as high melting point (up to 3410°C) and high density (19.3g/cm³). The addition of nickel effectively enhances the alloy's strength and toughness while improving its machinability, making the originally hard-to-process tungsten relatively easier for mechanical processing. Copper also plays a vital role: it not only improves the alloy's electrical and thermal conductivity but also adjusts its density and thermal expansion coefficient, optimizing the comprehensive properties.

For example, W-Ni-Cu alloy components used in high-end electronic devices have strict requirements for electrical conductivity and thermal stability. By precisely controlling the content ratio of nickel and copper and adding trace elements, the alloy can meet these demanding performance needs, ensuring stable operation of electronic devices in complex working environments.

II. Characteristics of Tungsten-Nickel-Copper Alloy

1. Density

W-Ni-Cu alloy boasts a remarkable density, typically ranging from 16.5 to 18.75 g/cm³, making it a genuine high-density alloy. This characteristic enables it to play a key role in applications requiring weight addition or center-of-gravity stabilization. For instance, in aerospace, satellite and aircraft components use W-Ni-Cu alloy for balance counterweights. By precisely adjusting the weight distribution, it ensures the stability and maneuverability of aircraft during high-speed flight or complex orbital operations.

2. Strength

The alloy exhibits excellent strength, with a tensile strength of 700-1000 MPa. This means it can withstand significant tensile forces without breaking. In high-pressure and high-load environments, such as key structural components of deep-sea exploration equipment or drill bits in oil extraction, W-Ni-Cu alloy works stably and reliably, effectively extending equipment service life and reducing maintenance costs.

3. Outstanding Thermal Conductivity

W-Ni-Cu alloy has a remarkable thermal conductivity, making it a star in electronic device heat dissipation. For example, heat sinks for computer CPUs and heat dissipation substrates for high-power LED lights use this alloy to quickly transfer heat, ensuring electronic components operate within suitable temperature ranges, improving equipment stability and reliability, and extending service life.

4. Good Electrical Conductivity

With good electrical conductivity, W-Ni-Cu alloy is widely applied in the electronics and electrical industry. Examples include electrical contacts for high-voltage switches and electrodes for electrical processing, which can operate stably under high-current and high-voltage conditions, ensuring normal power transmission and electrical equipment operation.

5. Low Thermal Expansion Coefficient

The thermal expansion coefficient is a key indicator of a material's dimensional stability under temperature changes. W-Ni-Cu alloy has a low thermal expansion coefficient, enabling it to maintain high dimensional stability in environments with large temperature fluctuations. For instance, high-temperature components of aircraft engines and precision parts in electronic devices experience drastic temperature changes during operation. If the material has a high thermal expansion coefficient, components are prone to deformation or damage. W-Ni-Cu alloy avoids such issues with its low coefficient, ensuring high-precision equipment operation.

6. Good Machinability and Weldability

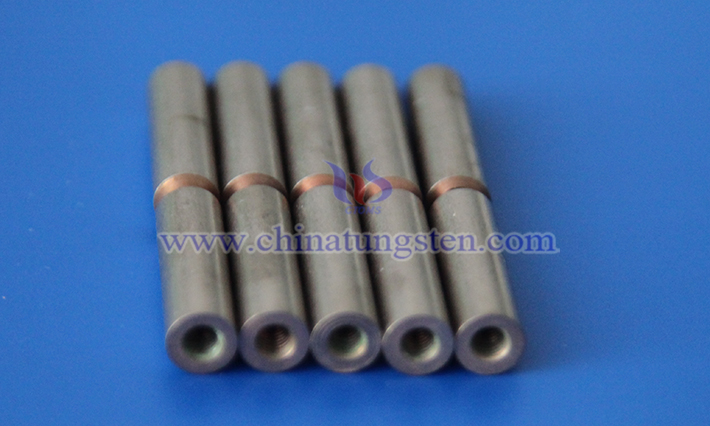

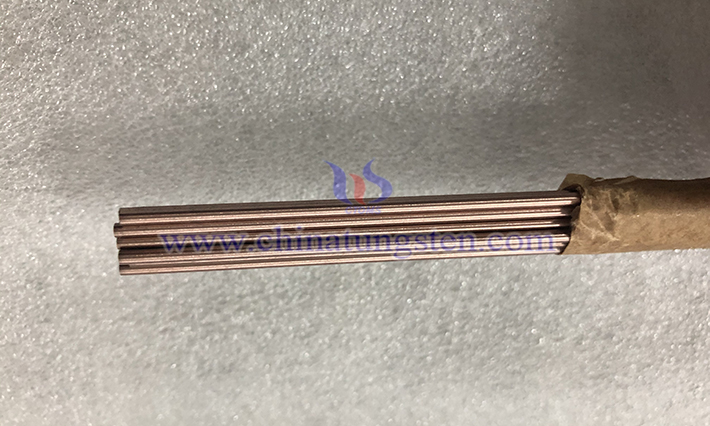

Unlike many high-performance materials, W-Ni-Cu alloy features excellent machinability and weldability. It can be processed into complex-shaped components through conventional techniques like turning, milling, drilling, and grinding to meet perse needs across industries. Additionally, it is easy to weld, allowing reliable connection with other metal materials, which facilitates manufacturing large and complex products—such as aerospace structural components or multi-layer circuit boards in electronics—greatly improving production efficiency and product quality.

7. Non-Ferromagnetic Property

W-Ni-Cu alloy is non-ferromagnetic due to the absence of ferromagnetic elements like iron and cobalt, which prevents ordered arrangement of atomic magnetic moments. This property makes it widely used in scenarios requiring anti-magnetic interference:

As shielding cases for precision instruments to resist magnetic field impacts on equipment accuracy;

As sensor components in aerospace to avoid magnetic signal interference;

As casings for electronic components to ensure stable circuit operation, making it an ideal material in the electromagnetic compatibility field.

III. Application Fields of Tungsten-Nickel-Copper Alloy

1. Aerospace Field

In the high-tech aerospace sector, where component material performance requirements are extremely demanding, W-Ni-Cu alloy becomes an ideal choice for manufacturing key components due to its exceptional comprehensive properties, including high melting point, high strength, good thermal stability, and thermal fatigue resistance.

2. Electronics Field

With the development of electronic technology, the miniaturization and high-performance trends of devices impose stricter requirements on heat dissipation and stability. W-Ni-Cu alloy is widely used in electronics for its unique advantages:

In electronic devices like computers, mobile phones, and servers, core components such as processors and graphics cards generate significant heat during operation. The alloy's excellent thermal conductivity allows heat sinks and thermal conductive plates to quickly transfer heat, which is then dissipated through cooling fins and fans, effectively reducing component temperatures and ensuring stable, reliable operation under long-term high-load conditions.

In electronic circuits requiring high resistance accuracy and stability (e.g., precision measuring instruments and high-end electronics), resistors made from this alloy ensure accurate and stable resistance values under different working conditions, providing reliable support for normal circuit operation.

3. Power Industry Field

In the power sector, where equipment must operate stably under complex conditions like high voltage, high current, and high temperature, W-Ni-Cu alloy stands out as an excellent material for manufacturing high-temperature resistors, resistance sheets, and electrical connectors due to its outstanding high-temperature stability and good electrical conductivity:

High-temperature resistors in high-voltage transmission lines, made from W-Ni-Cu alloy, maintain stable resistance values in high-temperature environments and withstand high currents and power, ensuring normal power system operation—such as resistors used for current limiting and voltage pision in high-voltage substations.

Electrical connectors, as key components connecting electrical elements in power equipment, made from this alloy maintain good electrical conductivity and contact stability under high-current and high-voltage conditions, reducing contact resistance and power loss, preventing electrical accidents, and ensuring reliable operation of power equipment.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com